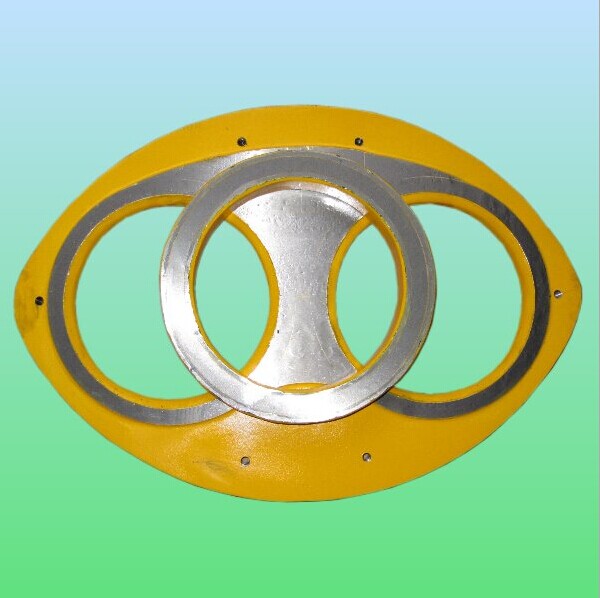

Zoomlion Spectacle Wear Plate and Cutting Ring DN200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

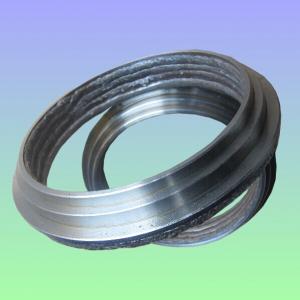

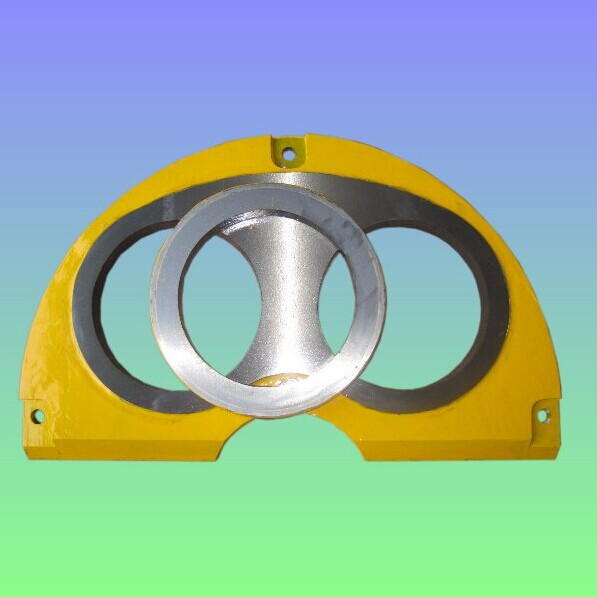

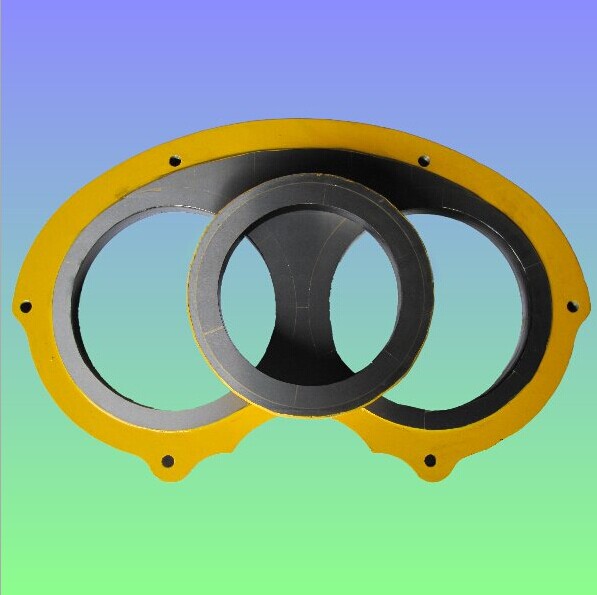

Product Name:Zoomlion Spectacle Wear Plate and Cutting Ring DN200

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade.

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 25000 N/mm2

6. Application: trailer and trunk mounted Zoomlion concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our Zoomlion Spectacle Wear Plate and Cutting Ring DN200 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs Zoomlion Spectacle Wear Plate and Cutting Ring DN200 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Zoomlion Spectacle Wear Plate and Cutting Ring DN200 according to customers request?

A4: Yes, we can produce Zoomlion Spectacle Wear Plate and Cutting Ring DN200 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: How often should hopper screens be cleaned or replaced?

- Hopper screens should be cleaned or replaced on a regular basis, typically every 3 to 6 months, depending on usage and the type of materials being processed. Regular cleaning of the hopper screens is essential to maintain optimal performance and prevent clogging or blockages. If the screens become excessively dirty or damaged, they should be replaced immediately to ensure uninterrupted flow of materials and prevent any potential damage to the equipment. Regular maintenance and inspections of the hopper screens will help to prolong their lifespan and ensure smooth operation of the entire system.

- Q: How do I identify the right spare part for my concrete pump model?

- To identify the right spare part for your concrete pump model, there are a few steps you can follow: 1. Refer to the manufacturer's manual: The manufacturer's manual is the best place to start as it usually provides detailed information about the concrete pump model and the corresponding spare parts. Look for the part numbers, descriptions, and any specific instructions for ordering or replacing parts. 2. Research online: Use the internet to search for your concrete pump model and related spare parts. Many manufacturers have official websites or authorized distributors that offer product catalogs or online databases where you can search for the specific part you need. Look for compatibility charts or diagrams that match your concrete pump model with the appropriate spare parts. 3. Consult with a specialist: If you're unsure about the compatibility or availability of spare parts for your concrete pump model, it's a good idea to consult with a specialist. Reach out to the manufacturer's customer service or contact a local distributor or service center that specializes in concrete pumps. Provide them with the details of your pump model and the specific part you are looking for, and they should be able to guide you in identifying the right spare part. 4. Check with other concrete pump owners: Reach out to other concrete pump owners or operators who have the same or a similar model as yours. They may have experience with finding and replacing spare parts and can provide recommendations or tips on where to look or who to contact. Remember, it is crucial to ensure that the spare part you choose is compatible with your concrete pump model to avoid any damage or malfunction. Taking the time to research and consult with experts will help you identify the right spare part and keep your concrete pump running smoothly.

- Q: Can concrete pump spare parts be painted or coated for increased durability?

- Yes, concrete pump spare parts can be painted or coated to increase their durability. The paint or coating acts as a protective layer, preventing corrosion and wear and tear, thus extending the lifespan of the spare parts.

- Q: Are there any specific guidelines for the disposal of packaging materials of concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of packaging materials of concrete pump spare parts. It is generally recommended to follow the local waste management regulations and guidelines provided by the respective authorities. Firstly, it is important to separate the different types of packaging materials such as cardboard boxes, plastic wraps, foam inserts, and any other materials used for packaging the concrete pump spare parts. This will enable efficient recycling or proper disposal of each material. Cardboard boxes can typically be recycled by flattening them and placing them in the designated recycling bins. Plastic wraps should also be separated and disposed of in specific recycling bins for plastics. Foam inserts, which are commonly used for protecting the spare parts, may not be recyclable in all areas and should be checked for specific recycling instructions. If recycling is not possible, foam inserts can be disposed of in regular waste bins. It is important to ensure that all packaging materials are free from any residual concrete or other hazardous substances before disposal. Any contamination should be properly cleaned or removed to prevent environmental pollution. If the packaging materials cannot be recycled or disposed of through regular waste management methods, it is recommended to contact local recycling centers or waste management facilities to inquire about specific disposal options for these materials. They may provide guidance or accept these materials for specialized processing or disposal. Overall, it is crucial to prioritize responsible waste management practices and comply with the specific guidelines provided by local authorities to ensure the proper disposal of packaging materials of concrete pump spare parts.

- Q: What are the types, classifications and specifications of concrete pump?

- In accordance with the export pressure rating label, divided into low pressure pump (5MPa), medium pressure and high pressure pump pump (6-10MPs) (>10MPa)

- Q: How can you determine when a concrete pump pipe needs to be replaced?

- Determining whether a concrete pump pipe requires replacement involves several factors to consider. 1. Visual Examination: Thoroughly inspect the pipe visually, searching for cracks, damages, or indications of wear and tear. Pay close attention to the pipe's ends where it connects to the pump and nozzle, as these regions are more susceptible to damage. 2. Performance Assessment: Observe the concrete pump's performance. If there is a decline in pumping efficiency, such as reduced output or difficulties in maintaining pressure, it may indicate a pipe problem. Furthermore, excessive leakage or blockages in the pipe could signify the need for replacement. 3. Age and Usage: Take into account the pipe's age and the extent of its usage. Concrete pump pipes have a limited lifespan, and over time and extensive use, they can deteriorate and lose their structural integrity. If the pipe is old and has undergone substantial use, it might be time for a replacement. 4. Regular Maintenance and Repairs: Frequent repairs or maintenance on the pipe could suggest that it is approaching the end of its lifespan. While regular maintenance can extend the pipe's life, if repairs are becoming more frequent and costly, it may be more cost-effective to replace it. 5. Safety Considerations: Prioritize safety when deciding on pipe replacement. If there are significant structural issues or concerns about the pipe's ability to handle pressure, it is crucial to replace it to prevent potential accidents or hazardous situations. Ultimately, the decision to replace a concrete pump pipe should be based on a combination of visual inspection, performance evaluation, age, usage, regular maintenance, and safety considerations. It is advisable to seek guidance from a professional or experienced technician who can assess the pipe's condition and offer expert advice on whether replacement is necessary.

- Q: How do I properly maintain and replace filters in concrete pump spare parts?

- Proper maintenance and replacement of filters in concrete pump spare parts is crucial for ensuring the smooth and efficient operation of the equipment. Here are a few steps to follow: 1. Regular Inspection: Regularly inspect the filters for any signs of wear, clogs, or damage. Clean or replace them as necessary to maintain optimal performance. 2. Cleaning: If the filters are reusable, clean them according to the manufacturer's instructions. Use compressed air or a mild detergent solution to remove dirt, debris, and clogs. Ensure the filters are completely dry before reinstalling them. 3. Filter Replacement: If the filters are disposable or damaged beyond repair, replace them with suitable replacements recommended by the manufacturer. Ensure that the new filters are of the correct size and specifications. 4. Replacement Schedule: Follow the recommended replacement schedule provided by the manufacturer. Filters may need to be replaced based on usage hours, operating conditions, or as part of routine maintenance. Adhering to this schedule will help prevent premature wear and maintain the efficiency of the concrete pump. 5. Proper Installation: When replacing filters, ensure they are installed correctly, following the manufacturer's instructions. Improper installation can lead to leaks, reduced performance, or damage to the concrete pump. 6. Record Keeping: Maintain a record of filter replacements, cleaning, and maintenance activities. This will help track the lifespan of filters, anticipate replacement needs, and ensure timely maintenance. By following these steps, you can ensure that the filters in your concrete pump spare parts are properly maintained and replaced, promoting the longevity and efficiency of the equipment.

- Q: How often should carbide wear plates be replaced in a concrete pump?

- The replacement frequency of carbide wear plates in a concrete pump is dependent on various factors. These include the type and quality of the plates, the intensity of usage, and the specific operating conditions of the pump. Carbide wear plates are designed to withstand the abrasive nature of concrete and generally have a longer lifespan compared to traditional steel plates. However, they are not immune to deterioration and will eventually wear down over time. A good practice is to regularly inspect the wear plates and assess their condition. If there are visible cracks, excessive erosion, or a decrease in concrete flow performance, it is time to consider replacing them. Replacement intervals can vary, ranging from annual replacements to several years. To extend the lifespan of carbide wear plates, proper maintenance and care are crucial. This includes regular cleaning, ensuring proper lubrication, and avoiding excessive pressure or abuse during operation. By conducting regular maintenance, the wear plates can last longer and replacements can be less frequent. It is advisable to consult the manufacturer's guidelines or seek advice from a professional concrete pump technician to determine the specific replacement interval for carbide wear plates in a particular pump model. Their expertise and knowledge will provide accurate recommendations based on the specific conditions and usage of the concrete pump.

- Q: Do concrete pump spare parts come with a warranty?

- Yes, concrete pump spare parts do come with a warranty. The warranty period may vary depending on the manufacturer and the specific part being purchased. Generally, reputable manufacturers and suppliers offer warranties on their spare parts to provide assurance to customers about the quality and reliability of the product. It is important to carefully review the terms and conditions of the warranty to understand what is covered and for how long. If any defects or issues arise during the warranty period, customers can typically get a replacement or have the part repaired at no additional cost.

- Q: What is the role of a concrete pump hopper agitator shaft?

- The role of a concrete pump hopper agitator shaft is to ensure the consistent and uniform mixing of concrete within the hopper. The agitator shaft is typically fitted with a series of paddles or blades that rotate within the hopper, effectively stirring the concrete and preventing it from settling or separating. This helps to maintain the desired fluidity and consistency of the concrete, allowing for smooth and efficient pumping without any blockages or clogs. The agitator shaft also helps to dislodge any hardened or stuck concrete, ensuring that the hopper remains clean and free from any obstructions. Overall, the agitator shaft plays a crucial role in keeping the concrete well-mixed and ready for pumping, thereby enhancing the performance and productivity of the concrete pump.

Send your message to us

Zoomlion Spectacle Wear Plate and Cutting Ring DN200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords