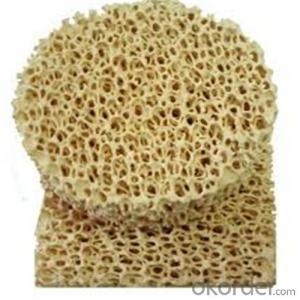

Ceramic Filter Plate for Foundry Zirconia Ceramic Foam Filter

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Alumina Ceramic Foam Filter for Foundry Industry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | as customers' requirement,usually carton and pallet |

| Delivery Detail: | 7-15 days after receiving the downpayment |

Specifications

Alumina ceramic foam filter

1.even aperture, high porosity, proper sinter

2.high strength of anti-flexing and anti-compression

Application:

For the filtration of molten steel and alloy,large scale iron casting

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

Form A Ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2

| Pressure resistence intensity in normal temperature N/cm2

| Pressure resistence intensity in high temperature N/cm2

| Refractory temperature

| Air discharging capability cm3/g

| Porosity %

|

15-100 | 10-45 | 0.35-0.45 | ≥38 | ≥80 | ≥45 | ≥1800 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of ceramic foam filter

Specification mm | Area M2

| Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

178X178X50 | 0.0213 | 57.00 | 25-45 | 4.2 |

229X229X50 | 0.0387 | 118.00 | 35-102 | 6.9 |

305X305X50 | 0.0745 | 198.00 | 90-165 | 13.8 |

381X381X50 | 0.122 | 325.80 | 130-265 | 23.2 |

432X432X50 | 0.160 | 427.20 | 210-350 | 34.5 |

508X508X50 | 0.227 | 606.60 | 280-465 | 43.7 |

585X585X50 | 0.341 | 772.20 | 370-540 | 57.3 |

Other products:

Our Team

Welcome to visit our factory~

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: What filter material are placed in the aquarium filter?

- Generally let off the filter cotton and ceramic rings, there are biochemical balls, coral bone, stone, activated carbon and so onConditional: filter cotton, ceramic ring, biochemical ball, coral bone, stone, activated carbon

- Q: Why does not the iron filter of the ceramic filter work?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Equipment comes with cleaning:Ceramic filter comes with a combined cleaning system, usually to ensure the normal backwash water pressure, combined cleaning (nitric acid + ultrasonic + backwash) time is sufficient, sufficient amount of nitric acid.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- The backwashing system of ceramic filter is usually made up of water inlet, water inlet, pressure gauge, water filter and filtered water pressure gauge, and then connected to the inside of ceramic filter. Such as the discovery of ceramic filter recoil pressure became smaller or even no recoil pressure, you can carefully observe the surface of the ceramic filter plate is wet or ceramic filter plate wear without water injection at the discharge point, investigation and the reasons for the following aspects:Is the water inlet pressure or normal?How about the sealing performance of the water filter? Does the filter element need to be replaced?Is the recoil system piping (metal pipe, ceramic filter plate, connecting pipe, etc.) broken, leaking or dripping?Is the distributor valve properly installed and is it worn?Are there any cracks in the ceramic filter plate?Is the pressure gauge broken?The most likely reason is 1, 2, two, the best water should not be too dirty, filter should be replaced regularly. I hope the answer can help you.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- First, the fineness of the material, resulting in the filter board filter cake moistureTwo, the vacuum can not reach, in the circumstances, whether the vacuum pipe leak

Send your message to us

Ceramic Filter Plate for Foundry Zirconia Ceramic Foam Filter

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords