Xps Blue Board Melbourne - BP XPS Insulation Board with Lower Thermal Conductivity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 64 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

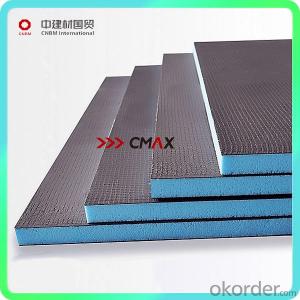

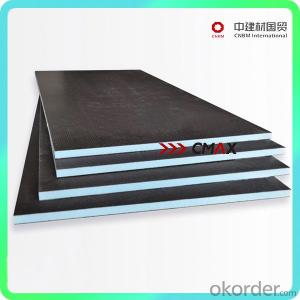

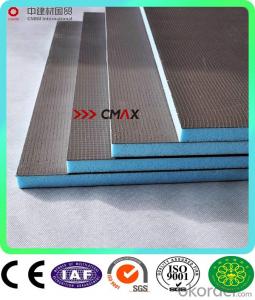

BP XPS insulation board lower thermal conductivity

BP XPS is a extruded polystyrene thermal insulation foam board with proven high performance characteristics. its strengths speaks for itself, having a uniform closed cell rigid structure with virtual zero voids/pathways for moisture to enter. Offering high compressive strength with lower thermal conductivity, dimensional stability and resistance to below ground decay.

Applications:

It's widely used in wall insulation, cold storage, parking platforms, airport, railway, concrete roof construction, highways, etc.

Advantages:

1. high compression resistance

2. moisture-proof

3. airtight

4. non-absorbent

5. corrosion resistance

6. low thermal conductivity

7. lightweight

8. Life time:60 years

9. environmentally friendly

Certifications

| Technical Data Sheet | |||

| Extruded Sheet (XPS) | |||

| Model | ×200 ×250 ×350 | ×400 ×450 ×500 ×600 | ×650 ×700 ×800 |

| Thermal Conductivity w/mk | 0.026 0.027 0.030 0.032-0.035 | ||

| Dimensional Stability | 0.3-1.0 | ||

| Applicable Temperature | -50°C - +75°C | ||

| Compression Strength kpa | 200 250 350 400 450 500 600 650 700 800 | ||

| Water Absorption | 0.3-1.0 | ||

| Density kg/m3 | 30-33 33-36 36-40 43-53 | ||

| Combustion Performance | GB8624-2012 Grade A, Grade B1 and Grade B2; GB8624-2006 Grade C or Grade B; GB8624-1997 Grade B1, | ||

| Oxygen Index | IO26-33 | ||

| Length | 1200 1450 1800 2400 | ||

| Width | 600 1200 | ||

| Thickness | 5 10 20 25 30 40 50 60 70 80 90 100 120 | ||

| Edge Shape | SS Flat Top SL Lap Joint TG Tenon RC Rain Gutter | ||

| Surface | Embossing Slotting Planing Smooth Surface | ||

| Applications | Insulation and Energy-Saving for Building Walls; Heat Preservation and Insulation for Cold Storage; Heat Preservation and Insulation for Roof; Stops and Side Panel on High-Speed Rail and Roads; Duct Pipe for Central Air Conditioner; Hydraulic Projects | Heat preservation and insulation for cold storage ground, steel-work roof, concrete roof construction; Frost-heave control for high-speed road, railway and airfield runway. | High-speed rail, CRTS track; Heavy cold storage ground. |

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Caigang rock wool sandwich panel Scope Caigang rock wool sandwich panels for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling , Cut off and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding the right amount of binder, curing processing and made. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on. Color rock wool sandwich panels Product Features 1. Rock wool is inorganic insulation materials, iron ore slag as the main raw material, by melting, with high-pressure steam jet cooling, with a light, thermal conductivity is small, good elasticity , Non-combustible, non-rotting, non-rotting, chemical stability, and excellent sound insulation.2 The rock wool sandwich panels are widely used in addition to the general structure of heat insulation and insulation To the use of a variety of fire insulation places. Caigang rock wool sandwich board specifications thickness Caigang rock wool sandwich board sub-system board and manual board two, Caigang sandwich panel is made of two layers of color coated steel Layer, through the automatic compound molding machine, in the steel plate coated with adhesive glue, while embedded in the board on both sides of the thin-walled steel, the pressure, blanking made of sheet metal. . the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × . L × 1150 × . L × 1150 × . handmade rock wool color steel sandwich panel specifications: L × 985 × . Sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. . rock wool density: ≥ 120kg / m. thermal conductivity: ≤ 0.046w / m.k. combustion performance: A-level (non-combustible)

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- The cast iron pipe is the old type of hand-cast iron pipe, which is a non-flexible pipe

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- That is, can be in the farthest bowel forging forging treadmill punch fist away from the pull up the most important things tower crane top of the car can move back and forth he moved to the farthest place to pull up the heaviest weight is slightly! The

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q: What is the difference between an extruded board and an XPS extruded board?

- What is the form of this, and you want to be on the scene to be helmet helmet helmet gnome insects rhinoceros kitery to be set. But single, double row scaffolding with a high degree of single-row scaffolding should not exceed 24M, double row scaffolding erection height can not exceed 50 meters, more than 50 meters high double scaffolding should be double pipe, sub-unloading, sub-erection and other measures The "Technical Specification for Safety of Fastener Steel Scaffolding" JGJ130-2011

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Extruded polystyrene board with XPS insulation board is no different, because it is the same thing two kinds of name. Extrusion polystyrene board full name is extruded polystyrene foam board, referred to as extruded plate, also known as XPS board, extruded polystyrene board. Extrusion polystyrene board use: 1 & gt; widely used in wall insulation, flat concrete roof and steel roof insulation; 2 & gt; for low temperature storage ground, parking platform, airport runway, highway and other areas of moisture insulation. Extruded plate is polystyrene resin supplemented by polymer in the heating and mixing at the same time, into the catalyst, and then extruded out of continuous closed-cell foam foam foam, the internal independent of the closed bubble structure, It is a kind of environment-friendly insulation material with high compression resistance, low moisture absorption, moisture-proof, airtight, light weight, corrosion resistance, super-aging resistance (almost no aging for long-term use) and low thermal conductivity. Extruded board is widely used in dry wall insulation, flat concrete roof and roof insulation of steel roof, low temperature storage floor, low temperature floor radiant heating heating pipe, parking platform, airport runway, highway and other areas of moisture insulation, Frost heave, is the construction industry inexpensive, excellent quality of the insulation, moisture-proof material.

- Q: How to distinguish between good and bad insulation board insulation board

- Class flexible management refers to the class teacher in the student's psychological and behavioral laws on the basis of the use of non-mandatory way, in the minds of students to produce a potential persuasive, the use of the class teacher's own positive factors to influence and guide students

Send your message to us

Xps Blue Board Melbourne - BP XPS Insulation Board with Lower Thermal Conductivity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 64 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords