WPC Tile CE certificate Passed For Sale From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Engineered Flooring

| Material | 35% environmental plastic materials(Grade A Recycled HDPE ) 55% natural wood fiber 10% chemical additives. (Anti-UV agent, Anti-oxidation agent, stabilizers, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants.)

|

| Surface Treatment | Surface Treatment: WG(wood Grain) DP(Dull poush) TN(Thin tooth) MM(Medium Tooth) TK(Thick Tooth) Smooth, Brushed, Scratched, Grained,Sanded

|

| Weight per meter | 1.37 kg/piece Custom made

|

| Size | 300*300*20mm Custom made,For more size,please send an inquiry to us.

|

| Colors |  |

| Application | Garden, Lawn, Balcony, Corridor, Garage, veranda Pool&SPA Surrounds, Boardwalk, Playground

|

| Characteristics | 1. Looks and feels like natural wood 2. Durable, firm because of its high density 3. High degree of UV and color stability, 4. Easy to install and low labor cost 5. Requires no painting, no glue, low maintenance 6. 100% recycle, environmental friendly, saving forest resources 7. Barefoot friendly, anti-slip, no cracking 8. Weather resistant, suitable from -60 to 60.

|

| Installment | Step 1:Put the keel in the bottom with the recommended 30-40cm distance Step 2:Dig a 1.5cm-deep hole and put the nail in. Step 3:Combine the two boards and tighten the screw.

|

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

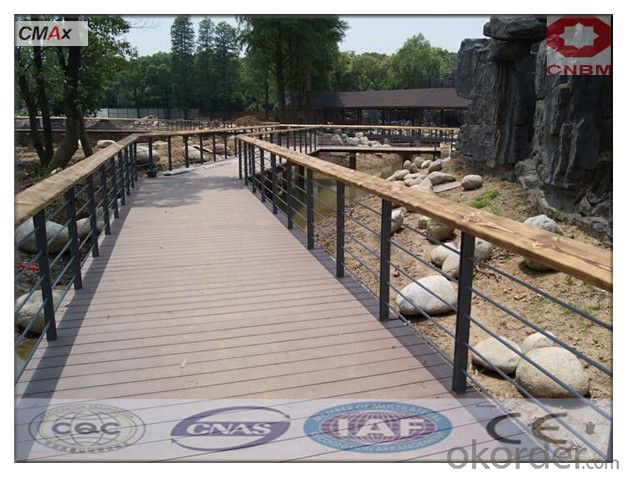

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: What is the price of a composite floor?

- The general about 100 in a little bit, the quality can be, there are dozens of cheap, expensive is also very expensive, and now out of the multi-storey composite floor, in this piece to do a good yet far, Fen Huan pet but a good amount of touch, wear resistance and resistance to deformation are very good

- Q: My house up and down the floor of the water there is not much water above the floor there is water just started with the foot of the wall on the edge of the wall will have water overflow from the wall after an hour after the top of the skeleton repair Lennon agent Yi Chuan floor now basically no It is estimated that the penetration of the floor has been in the first time to open the door to open the door which the Supreme who knows the floor will be deformed? Can not use it? Do not open? Is the best professional answer more

- First of all to be able to deal with the water first clean, the floor of the water for the time being to ignore it, the floor is the main water to keep the ventilation to make it natural dry, if the top of the skeleton repair Lennon agent Wang Chuan floor is removed, the floor But will be deformed, in order to let the floor as soon as possible, you can remove the buckle, the baseboard if it is easy to remove the water can be evaporated as soon as possible.

- Q: My house decoration, the boss gave us to pay off the grass barnyard grass carpets, but the floor of the floor, and because of the uneven floor, after the shop a wall to another wall difference 10 cm or more, the cup can clearly see the tilt, it means that I sleep is head down feet up, ask what way to solve. More

- 6-7 cm, there are 10 cm deviation, what concept. Say you shop composite floor to 6-7 cm bubble doing? First of all to give you a guide to the views of the composite floor is divided into solid wood composite and compulsory Gong barnyard grass weaving locust semi-Lian Lian Lian compound, these two kinds of boards can be laid on the cement! The premise is the ground to be flat, the need for keel is not big, so much deviation, how much keel to borrow? joke! First the first thing to remove the floor, take all the bubbles below and then do the leveling of the cement! Find a good shop after the floor, installed baseboard!

- Q: What are the shortcomings of the bright composite floor?

- The unique structure of the solid wood composite flooring is an important reason for its superior performance. At the same time, such a structure also makes it in the production process than to avoid the use of a lot of glue, solid wood flooring each layer is glue glue. Currently on the market, solid wood flooring is divided into three layers with multi-storey (5 or 7). The more layers, the greater the amount of glue used.

- Q: My house is decorated with a composite floor. Belong to the matt for the floating pile of spring nothing wrong Tong Feng Kun asked: whether the floor with essential oils or floor wax what the floor into the light? How can i be able to keep it long? Is the floor oil or floor wax harmful to the body? What is the average price? Thank you more

- To the composite floor waxing (or essential oil) there are two problems: 1, the floor does not absorb, each time playing the wax, accumulated to a certain thickness, you need to remove the wax. 2 to maintain a short time, every month a cycle, once the stop waxing, cracking, dirty phenomenon will produce, the effect is not as good as that of the ground, Never played. Specific fight and do not fight, you make your own ideas. My advice is: do not do maintenance to the composite floor. Floor oil and floor wax do not hurt the body. Price range: solid boxed ----- 10 yuan; spray pot ----- 20 yuan; liquid bottled ----- 30-40 yuan (including essential oils and wax); paste Natural ingredients ---- 100 yuan or so.

- Q: How to take care of composite floor

- Upstairs to answer? Strengthen the composite floor basically do not need special care, because the strengthening of the composite floor of the surface is aluminum oxide, is a chemical composition, the general stains will not be invaded, only need not to use the drip on the OK The How to take care of the words, there is a building materials supermarkets to strengthen the floor of the oil can be considered, but it is nothing more than the top ten scrapped version of the calcium version of the water to shock the floor to polish a little more clear, no practical effect, so no need to spend this Money! Do not strengthen the composite floor must not wax, especially solid wax, if hit, the floor will become very flower and blurred, it is not easy to clean up! Counterproductive! I can be responsible for the above answer!

- Q: Home with wooden floor or tiles good?

- Tiles and flooring can be said to have their own strengths and weaknesses, each other pros and cons, if the economy can bear the words, or home with the elderly and children, it is best to shop solid wood flooring, warm, good foot feeling, but the price is high, Too troublesome. Followed by the whole pavement parquet, so warm and comfortable, care is also simple. But if more guests at home, the living room on the choice of floor tiles, bedroom selection of solid wood flooring, so relatively practical point. Floor tiles have a lot of benefits, environmental protection is better, usually take care of simple, but the warmth is not good, the winter will appear some cool, in fact, many good tiles prices are not low, plus pavement costs, the overall count down Must be cheaper than the floor. So it is recommended to use solid wood flooring.

- Q: Or solid wood (also see what the wood, such as two-winged beans, etc.), but the composite price is better, not easy to change, good care.

- Look at the extent of the original damage to the floor, if there is no big problem directly shop is ah!

- Q: dont know which method to install engineered floor on concrete i live in upland ca . float on cork or redux underlayment.or glued downadhessive 3 in 1 best overall methods

- Which type of flooring (of the engineered) do you have? They come both ways and can be installed in the way they come. The flooring ( click and lock system) must be installed that way. Any other type, if they don t specify it, must be glued od stapled. And since you said over slab, it must be glued down. Each way works well, Just find the method you like since gluing can be messy and costly( for the glue) but easier for some people to install. And the floating system is a bit harder to do if your not handy. But is cheaper w/o glue. Any questions you can e mail me through my avatar. I ve attended several installation seminars as well as installed a few 100,000 s/f.. GL

- Q: Which brand of composite flooring is durable?

- Composite flooring is generally very durable, good composite floor brands are: the elephant, Cicero, Filingel, Del, Shengda, Kyrgyzstan, Yangtze, Sao Paulo and other well-known floor brand

Send your message to us

WPC Tile CE certificate Passed For Sale From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches