Geotextile Johor - Woven Geotextile / High Strength Multifilament Non Woven Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

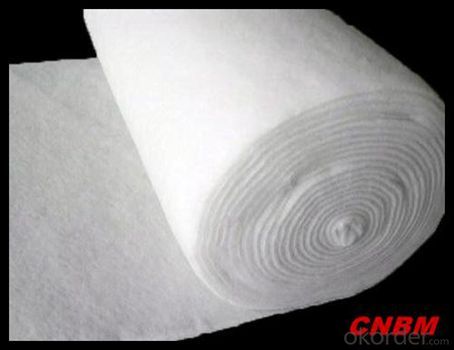

High Strength Multifilament Woven Geotextile / Non Woven Geotextile Fabric

The benefits :

High strength: the maximum can be up to 200kn/m

Corrosion resisitance

Permeation of water

easy to stor and transport

Durability

Specification sheet:

Description:

Multifilament Woven Geotextiles FWG® are made of individual multifilament yarns woven together into a

stable fabric structure with a superior combination of mechanical and hydraulic properties. These product series has excellent resistance to biological and chemical environments normally found in soils and are

stable against short-term exposure to ultraviolet radiation.

Applications:

Road and railway construction

Embankments and temporary retaining soil structures

Sludge pond cappings

Foundation of marine structures

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in athletic field construction?

- Yes, geotextiles can be used in athletic field construction. Geotextiles are commonly utilized in athletic field construction for various purposes such as erosion control, soil stabilization, and drainage management. They can help enhance the durability and performance of the field by preventing soil erosion, improving water drainage, and providing a stable base for the turf or playing surface.

- Q: what is the purpose of geotextile on gabion walls.?

- Geotextiles are fabrics associated with soil, earth or rocks. Gabions were earth filled barricades meant to halt enemy fire during battle. I'm guessing geotextiles on gabion walls more effectively hold back the earth or filler. They might have well suited permeability or retentive qualities for gabions. There are a few other definitions for gabions. But this is the militaristic definition. Gabions are also used in dams and such. In this case, geotxtiles might have good properties for being submerged in water and still retaining whats inside the gabions.

- Q: How do geotextiles affect soil settlement?

- Geotextiles can significantly affect soil settlement by providing reinforcement and stabilization. These synthetic materials help distribute the loads applied to the soil, reducing settlement and preventing soil movement. They also improve drainage and filtration, allowing water to pass through the soil more easily, minimizing the potential for settlement due to water accumulation. Overall, geotextiles play a crucial role in controlling soil settlement and maintaining the stability of various structures.

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing strength and stability to the bags. They act as a barrier and prevent the soil or other fill material from escaping through the pores of the bags. Additionally, the geotextiles distribute the weight of the fill material evenly, reducing the risk of bulging or bursting of the bags.

- Q: Can geotextiles be used in water retention projects?

- Yes, geotextiles can be used in water retention projects. Geotextiles are often used to reinforce soil and prevent erosion, making them suitable for applications such as retaining walls, embankments, and shoreline protection. In water retention projects, geotextiles can be used to create a barrier that traps water and prevents it from seeping into the surrounding soil, thereby increasing water retention.

- Q: How do geotextiles improve the performance of foundations?

- Geotextiles improve the performance of foundations by providing reinforcement, filtration, and separation functions. They increase the load-bearing capacity of the soil, distribute the load more evenly, and prevent the mixing of different soil layers. Additionally, geotextiles help to drain excess water, control soil erosion, and protect the foundation from potential damage.

- Q: What are the different geotextile installation techniques in filtration?

- There are several different geotextile installation techniques used in filtration, including direct placement, trench installation, and slope installation. Direct placement involves spreading the geotextile directly on the ground and securing it with stakes or sandbags. Trench installation involves placing the geotextile in a trench and backfilling it with soil. Slope installation is used on steep slopes and involves anchoring the geotextile with staples or other fasteners. These techniques help ensure proper filtration and erosion control in various applications.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: Water stable health with the geotextile, sticky on the water stable, how quickly cleared

- I professional production geomembrane / geotextile, the highest cost, I wish smooth

- Q: How do geotextiles help in stabilizing slopes for pipeline construction?

- Geotextiles help in stabilizing slopes for pipeline construction by providing reinforcement and erosion control. They are placed along the slope to prevent soil erosion and promote stability. The geotextiles act as a barrier, preventing the movement of soil particles and reducing the risk of slope failure. Additionally, they enhance the soil's strength and increase its resistance to erosion caused by water flow. Overall, geotextiles play a crucial role in maintaining the stability of slopes during pipeline construction.

Send your message to us

Geotextile Johor - Woven Geotextile / High Strength Multifilament Non Woven Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords