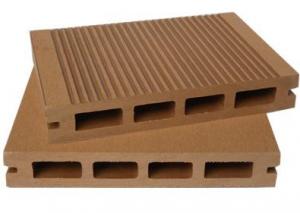

Wood Plastic Composite Panel Special Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Panel Special Shape

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of Wood Plastic Composite Panel Special Shape

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of Wood Plastic Composite Panel Special Shape

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of Wood Plastic Composite Panel Special Shape

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of Wood Plastic Composite Panel Special Shape

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: Is the plastic floor good or the carpet good in the room with the plastic floor or the carpet?

- Plastic (PVC) is not possible due to the release of formaldehyde, the domestic plastic floor (PVC floor) used in the production of additives is relatively poor, a serious odor, imported PVC floor adopts production technology and advanced production technology, to replace the pungent odor additives smell, so the PVC floor is at present the most environmentally friendly all the floor in the floor.

- Q: What are the reasons for the price rise of PVC plastic floor

- Defects are thermally stable and shock resistant are poor, both hard and soft PVC easy to produce brittle during use. General PVC is not containing the relevant national standards allow the use of two (2 - ethylhexyl) adipate plasticizer (DEHA), DEHA in the high temperature (over 100 degrees Celsius) easily released, after contact with human health hazard.

- Q: Can the bathroom PVC plastic floor?

- 1, can shop. But do not use ordinary plastic floor, recommended with coil, and the surface should have a concave and convex non slip texture, glue to use two components of waterproof glue line, the construction of more stringent.

- Q: How to spread plastic floor tiles

- Wet floor tile shop: cement and sand and water mixing into cement mortar (dry wet like rigid cement mortar plus a lot more). Before laying along the wall popped out of the ground elevation line, and then do the ash cake around the room, (ash cake is painted or pouring floor when Mason used to control the building elevation and surface flatness and verticality of cement blocks.) The surface of the cake should be lower than that of the floor, and the thickness of the floor tile should be lower. Finally, use a rubber hammer to crack down.

- Q: Technology of plastic floor

- Ground foundationFirst of all, to the construction site of the ground roughness, hardness, strength, humidity and humidity requirements

- Q: How to spread the plastic floor?

- On the ground roughness requirements are higher, the best time to install the floor glue

- Q: What are the disadvantages of PVC plastic floor

- PVC plastic floor has many advantages, it also has shortcomings, but compared to other plastic floor, PVC plastic floor has been considered a good

- Q: I asked about the "plastic" floor tile paving method, please describe its steps?

- Key tiles is flat ground, otherwise very easy to open or damaged floor brick. There are a lot of glue to the ground plate, can choose their own. Shop paste must be from the center to the surrounding, and some of the glue scraping after the need to be static 1 ~ 2 minutes after use. After sticking, the glue in the seam should be wiped off

- Q: What are the main construction process of laying plastic floor

- (2) soft plastic floor plate:Primary treatment, elastic line, plastic floor wax, degreasing, pre laying groove blanking, scraping, paste, welding, rolling, maintenance.

- Q: Such as the title, do not know what is the real wood floor shop? The following is the keel I am looking for the materials and the advantages and disadvantages, we have what opinions and suggestions might as well talk about... 4, keel laid the keel: many materials, the most traditional is also plastic, wood keel, wooden keel and so on Aluminum Alloy 1): on the ground drill, fixed wooden keel, wooden keel on surface leveling the floor with a nail, will start...Home renovation renovation of the old house, the living room plus two bedroom only 41 square meters, which is more suitable for...In addition, the room is small, the shop is too thin and good-looking and consumption of materials, want to shop 455*90*1.8 or 455*120*1.8

- Home is home renovation, so could not live for a long time, suggested the use of wooden keel, more environmentally friendly, but in which you want to add pepper and aniseed and lime mothproof, decadent

Send your message to us

Wood Plastic Composite Panel Special Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords