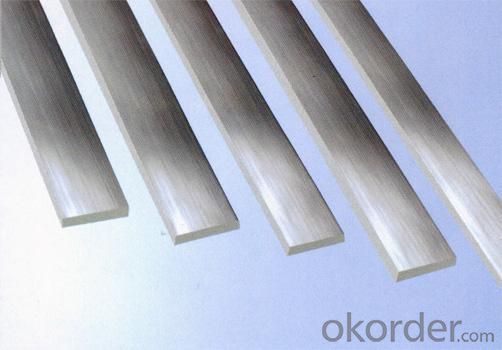

Wide Flat Bar High Quality Hot Rolled 3-30mm Q235 Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

High Quality Wide Flat Bar 3-30mm Q235 Hot Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality Wide Flat Bar 3-30mm Q235 Hot Rolled are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can steel flat bars be galvanized or coated with other materials?

- Yes, steel flat bars can be galvanized or coated with other materials. Galvanization is a process in which a protective layer of zinc is applied to the surface of the steel to prevent corrosion. This can be done by either hot-dip galvanizing, where the steel is dipped in molten zinc, or by electroplating, where a zinc coating is applied through an electrochemical process. Apart from galvanization, steel flat bars can also be coated with other materials for various purposes. These coatings can provide additional protection against corrosion, improve aesthetic appearance, or enhance specific properties of the steel. Some common coating materials used for steel flat bars include epoxy, polyurethane, powder coating, and paint. These coatings can be applied through different methods, such as spraying, dipping, or powder coating, depending on the specific requirements and desired outcome. The choice of coating material and method depends on various factors, such as the intended use of the steel flat bars, the environment in which they will be used, and the desired appearance or performance characteristics. It is important to consult with experts or professionals in the field to determine the most suitable coating option for your specific needs.

- Q: What are the fire-resistance properties of steel flat bars?

- With their exceptional fire-resistance properties, steel flat bars demonstrate great strength. Their resistance to high temperatures, without compromising their structural integrity, is noteworthy. Steel bars remain unaffected by fire, avoiding any contribution to the spreading of flames, thus making them a dependable option for fire-resistant structures. Moreover, their low thermal conductivity adds to their fire-resistance capabilities by preventing the easy transfer of heat. Consequently, steel flat bars are extensively employed in construction projects that prioritize fire safety.

- Q: Are steel flat bars suitable for making brackets or supports for fire protection systems?

- Yes, steel flat bars are suitable for making brackets or supports for fire protection systems. Steel is known for its strength and durability, making it a reliable material for constructing brackets or supports. Fire protection systems often require sturdy and heat-resistant components, and steel flat bars can meet these requirements. They can be easily fabricated and welded to create customized brackets or supports that can withstand the weight and stress of fire protection systems. Additionally, steel is non-combustible and has a high melting point, which further enhances its suitability for fire protection applications.

- Q: Are steel flat bars suitable for machining operations?

- Indeed, machining operations can be effectively carried out with steel flat bars. These bars are extensively utilized in a myriad of machining applications owing to their adaptability and robustness. Cutting, drilling, milling, and turning are among the diverse processes by which steel flat bars can be effortlessly machined. The bar's flat surface furnishes a steady and uniform material for machining, facilitating meticulous and precise operations. Moreover, steel flat bars exhibit exceptional strength and resilience, rendering them exceptionally suitable for arduous machining assignments. All things considered, steel flat bars emerge as a dependable option for machining operations in industries like manufacturing, construction, and automotive.

- Q: Are steel flat bars suitable for load-bearing structures in bridges?

- Yes, steel flat bars are suitable for load-bearing structures in bridges. Steel flat bars are commonly used in bridge construction due to their high strength and durability. They can withstand heavy loads and provide excellent structural support. Additionally, steel flat bars can be easily welded or bolted together, allowing for efficient construction and easy customization to meet specific bridge design requirements. These bars are also resistant to corrosion, which is crucial for bridge structures exposed to outdoor elements. Overall, steel flat bars are a reliable and cost-effective choice for load-bearing structures in bridges.

- Q: How do you protect steel flat bars from rusting?

- To protect steel flat bars from rusting, there are several measures you can take: 1. Apply a protective coating: One effective way to prevent rust on steel flat bars is to apply a protective coating. This can be done by using paints, varnishes, or specialized coatings designed specifically for metal protection. Ensure that the coating you choose is compatible with steel and provides adequate corrosion resistance. 2. Galvanization: Galvanizing steel flat bars is a common method to protect them from rust. In this process, a layer of zinc is applied to the surface of the steel, creating a barrier that prevents corrosion. Galvanized steel flat bars are highly resistant to rust and can withstand harsh environmental conditions. 3. Regular cleaning and maintenance: Keeping steel flat bars clean and free from dirt, moisture, and other contaminants is crucial to prevent rust formation. Regularly clean the surface of the bars using mild soaps or detergents, and dry them thoroughly to remove any moisture. Additionally, inspect the bars periodically for any signs of rust or damage, and address them promptly. 4. Store in a dry environment: Proper storage is essential to protect steel flat bars from rusting. Ensure that the bars are stored in a dry environment with controlled humidity levels. Avoid exposing them to excessive moisture, rain, or condensation, as these can accelerate the rusting process. If possible, store the bars indoors or use protective covers to shield them from moisture. 5. Use desiccants or moisture-absorbing materials: To further prevent rust formation, you can include moisture-absorbing materials such as desiccant packs or silica gel packets when storing steel flat bars. These materials help to absorb excess moisture in the surrounding environment, reducing the risk of rust formation. By implementing these measures, you can effectively protect steel flat bars from rusting and prolong their lifespan. Regular maintenance and vigilance are key to ensuring their long-term durability and preventing the costly consequences of rust damage.

- Q: What is flat steel, please?

- Steel strip steel rectangular and with pure edge of cold drawn steel, stainless steel flat steel. Stainless steel flat can be semi-finished steel. There are cold drawn polished stainless steel flat and hot-rolled acid white and sand blasting stainless steel flat. The raw material for producing stainless steel flat bar is stainless steel square billet, and the finished stainless steel flat bar is produced by hot rolling, normalizing or hot rolling, pickling (or sand blasting), cold drawing and polishing. The two sides are equal in width. The specifications are expressed in millimeters of edge width * * edge thickness. Such as 30 * 3, that is, width of 30 mm edge, 3 mm thick edge of stainless steel flat side.

- Q: Are steel flat bars suitable for high-temperature environments?

- When it comes to high-temperature environments, steel flat bars are generally a good choice. However, the type of steel and its maximum temperature tolerance will vary depending on the specific use. For instance, stainless steel flat bars are particularly known for their excellent resistance to heat and can withstand temperatures as high as 1500°F (816°C). They also have good mechanical properties, which means they can maintain their strength and shape even when exposed to high temperatures. Nevertheless, it is important to consider the unique requirements of each high-temperature environment. Factors such as the duration of exposure to high temperatures, the presence of corrosive substances, and the potential for thermal expansion or contraction must be taken into account. In some extreme situations, such as in furnaces, specialized high-temperature alloys or refractory metals may be more suitable. To ensure the best performance in a specific high-temperature application, it is always recommended to seek the advice of a materials engineer or specialist. They can assess the specific requirements and offer guidance on the most appropriate steel grade, heat treatment, and any additional protective measures that may be necessary.

- Q: Can lightning protection earthing steel bar be directly welded with thread steel?

- Steel is known as hot rolled ribbed bar. Ordinary hot rolled steel bars are made up of HRB and the minimum yield point of the brand. H, R, and B are the first letters in English for hot-rolled (Hotrolled), ribbed (Ribbed) and reinforced (Bars) three words. Hot rolled ribbed bar is divided into two levels, HRB335 (old No. 20MnSi), three HRB400 (20MnSiV, 20MnSiNb, old No. 20Mnti), four grade HRB500 three grade.

- Q: What is the minimum order quantity for steel flat bars?

- The minimum order quantity for steel flat bars may vary depending on the supplier or manufacturer. It is recommended to contact the specific supplier or manufacturer to inquire about their minimum order quantity for steel flat bars.

Send your message to us

Wide Flat Bar High Quality Hot Rolled 3-30mm Q235 Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords