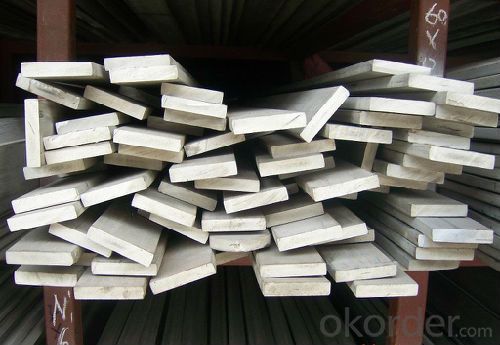

Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can steel flat bars be used for making frames or supports for solar panels?

- Yes, steel flat bars can be used for making frames or supports for solar panels. Steel is a strong and durable material that provides excellent structural support. It is often used in construction and engineering applications due to its high strength-to-weight ratio. Steel flat bars can be easily fabricated and welded to create custom frames or supports for solar panels. Additionally, steel is resistant to corrosion, which is important for outdoor installations where solar panels are exposed to various weather conditions. Overall, steel flat bars are a suitable choice for constructing frames or supports for solar panels, ensuring stability and longevity.

- Q: How do steel flat bars compare in terms of strength and durability?

- Steel flat bars are known for their exceptional strength and durability. Due to their flat shape, they offer enhanced load-bearing capacities and resistance to bending or warping. Additionally, steel flat bars are highly resilient against external impacts and corrosion. Overall, they are a reliable choice for applications requiring robustness and longevity.

- Q: Can steel flat bars be bent without cracking?

- Yes, steel flat bars can be bent without cracking, depending on their composition, thickness, and the bending process used. Steel is a highly malleable material, meaning it can be bent or shaped without breaking. However, it is important to note that the extent to which steel bars can be bent without cracking varies based on several factors. The composition of the steel is crucial in determining its flexibility and resistance to cracking. Different grades of steel have varying levels of ductility, with more ductile steels being better suited for bending without cracking. For instance, mild steel is known for its excellent ductility and is commonly used for bending operations without issues. The thickness of the steel bar also plays a role in its ability to withstand bending without cracking. Thinner bars are generally more prone to cracking, especially if the bending radius is too small. It is important to ensure that the bending process corresponds to the thickness of the steel bar to prevent cracking. The bending process itself is crucial in avoiding cracking. Generally, steel flat bars can be bent using different techniques such as cold bending or hot bending. Cold bending is typically performed at room temperature and involves slowly applying force to the bar until it reaches the desired shape. Hot bending, on the other hand, involves heating the steel bar to a specific temperature range before bending. The heat reduces the risk of cracking by increasing the material's ductility. Applying gradual and even pressure during the bending process is crucial to avoid cracking. Sharp or sudden bends can create stress concentrations, increasing the likelihood of cracking. It is recommended to use appropriate tools, such as bending machines or specialized dies, to ensure a controlled and uniform bending process. In summary, steel flat bars can be bent without cracking if the steel composition is suitable, the thickness is appropriate, and the bending process is carefully executed. It is always advisable to consult with experts or refer to specific guidelines and standards to ensure a successful and crack-free bending operation.

- Q: What is the maximum thickness available for steel flat bars?

- The maximum thickness available for steel flat bars can vary depending on the specific manufacturer and supplier. However, typically, steel flat bars can be found in thicknesses ranging from 1/8 inch to 1 inch or more.

- Q: Can steel flat bars be used for making storage cabinets?

- Yes, steel flat bars can be used for making storage cabinets. Steel flat bars are sturdy and durable, making them suitable for constructing storage cabinets that can withstand heavy loads. They offer excellent structural integrity and can be easily welded or bolted together to create a stable and secure storage solution. Additionally, steel flat bars are resistant to rust and corrosion, ensuring the longevity of the storage cabinets. Therefore, using steel flat bars for making storage cabinets is a practical choice that can provide strength, durability, and a professional appearance.

- Q: Can steel flat bars be used in automotive applications?

- Yes, steel flat bars can be used in automotive applications. Steel flat bars are known for their strength, durability, and versatility, making them suitable for various automotive components and structures. They can be used in the construction of chassis frames, body panels, suspension components, and even in the fabrication of custom parts. The high tensile strength of steel flat bars allows them to withstand the significant forces and loads experienced by automotive parts during operation. Additionally, steel flat bars can be easily shaped, welded, and formed to meet the specific design requirements of automotive applications. Overall, the use of steel flat bars in automotive applications is common and widely accepted due to their excellent mechanical properties and cost-effectiveness.

- Q: How do you protect steel flat bars from chemical exposure?

- One way to protect steel flat bars from chemical exposure is by applying a protective coating or paint specifically designed for corrosion resistance. These coatings act as a barrier, preventing direct contact between the steel and the chemicals. Additionally, regular inspections and maintenance are important to identify any signs of corrosion or damage so that necessary repairs or recoating can be carried out promptly.

- Q: Are steel flat bars used in the construction of bridges?

- Yes, steel flat bars are commonly used in the construction of bridges. Flat bars, also known as flat steel, are often utilized as structural components in bridge construction due to their strength, durability, and versatility. These bars are typically made from carbon steel, which provides the required strength to support the weight and load of the bridge. Steel flat bars are used in various bridge components, including beams, trusses, and decking. They are often incorporated into the structural framework to distribute the load and provide stability, ensuring the bridge's overall integrity. Additionally, steel flat bars are highly resistant to corrosion, making them suitable for outdoor applications where bridges are exposed to environmental elements. Overall, steel flat bars play a crucial role in the construction of bridges, contributing to their strength, stability, and longevity.

- Q: Are steel flat bars used in the automotive industry?

- Steel flat bars are widely utilized in the automotive industry. They find application in the fabrication of chassis frames, suspension components, seat frames, and door reinforcements. The utilization of steel flat bars brings forth numerous benefits in automotive manufacturing, encompassing remarkable strength, durability, and cost-effectiveness. Their adaptability and ease of shaping and welding render them a favorable option for a multitude of automotive structural and non-structural components. Furthermore, steel flat bars exhibit exceptional resistance to impact and fatigue, thus guaranteeing the safety and longevity of vehicles.

- Q: Are steel flat bars suitable for welding projects?

- Yes, steel flat bars are suitable for welding projects. Steel flat bars are commonly used in welding projects due to their versatility and strength. They have a flat surface which makes them easy to work with and weld, allowing for precise and strong connections. Steel flat bars are available in various sizes and thicknesses, making them suitable for different types of welding projects. Additionally, steel is known for its durability and resistance to heat, which are important factors in welding. Overall, steel flat bars are a reliable and commonly used material for welding projects.

Send your message to us

Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords