Whole Aluminum Formwork with Different Size with Great Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

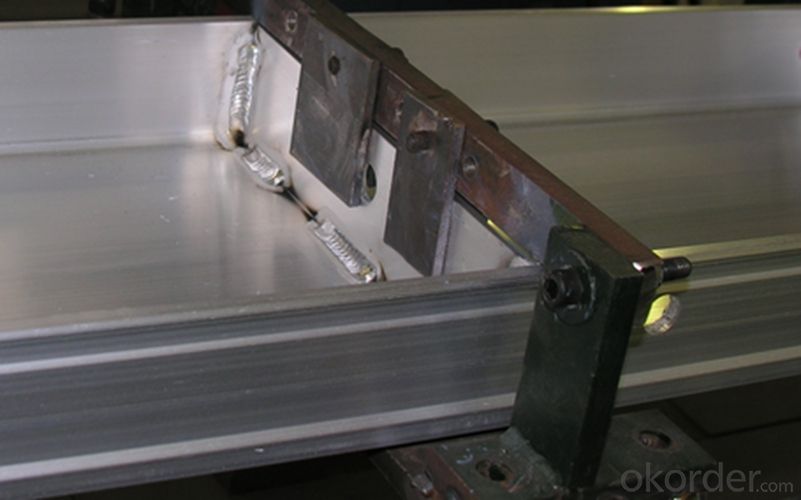

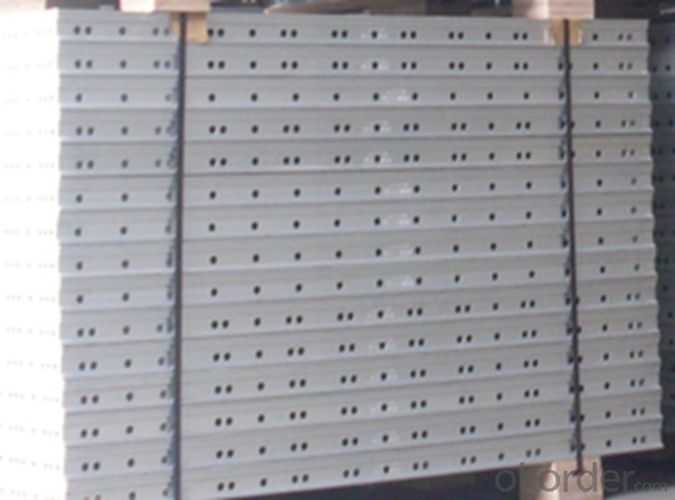

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

3. Whole Aluminum Formwork Images

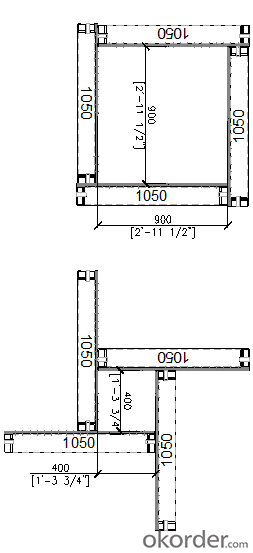

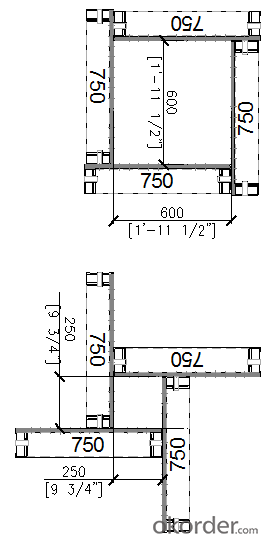

4.Whole Aluminum Formwork Specifications

1) MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2) DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3) StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4) StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

Please feel free to customize.

2) What promises can be done by us?

If interested in this kind of formwork, please feel free to write us for any QUOTE.

If need any technical and building assistance, we could provide on-site professional staff for instruction.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale services?

Response will be carried out in 24hours after receiving any complain or request.

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: What type of industry does the machinery and building accessories processing belong to?

- Every industry has average tax rate, the contribution of each this argument does not exist, the industrial enterprise is nade VAT. The more value-added products you pay more.

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- The whole circle of the triangle is welded as an angle weld, and the other is the outer circle with the same diameter as the two, so the butt joint is better to open the groove. Welding, for V type welding seam, and, technical requirements are generally, welding firm, no defects, welding smooth grinding, cleaning welding slag splash

- Q: What are the mechanical drawing software?

- The plane is mainly CAD and CAXA, there are some non mainstream mechanical engineer what, mainly engaged in your spare parts of machinery industry, roughness, form and position tolerance requirements, recommendations for CAXA, which symbols are readily available, there are standard parts library, mechanical symbols library etc..

- Q: China mechanical net

- From Chinese GM parts, general machinery, hardware, tools, instruments, electrical appliances and related equipment, textile equipment, chemical equipment, agriculture, food equipment, construction equipment, environmental protection equipment, mining equipment, metallurgical equipment, financial equipment, commercial vehicles and accessories, machinery processing equipment, machinery processing industry machinery enterprises and mechanical products

- Q: What is a door rack for a construction site? How high is it generally?

- Construction machinery network learned that the door scaffolding in our country production and use of time is not long, the scaffolding developed by the various research institutions, self-contained, and not common, varieties, specifications and diverse. Some factories copy foreign products and use the imperial size.

- Q: Where does Heilongjiang do the most construction machinery?

- All of the industry designated product range is roughly the same as that of China engineering machinery and other countries are also increased the railway engineering machinery, forklifts and industrial handling vehicles, decoration machinery, elevator, pneumatic tools and other industries.

- Q: What are the sub projects of a construction project?

- Lime soil, sand and gravel foundation, geosynthetics foundation, fly ash foundation, dynamic compaction, foundation grouting, preloading foundation, vibroflotation foundation, jet grouting foundation, cement mixing pile foundation, soil and lime soil compaction pile foundation, cement fly ash gravel pile, cement soil pile foundation. Based on sand pile foundation

- Q: What is the difference and connection between equipment manufacturing and machine building?

- When our company went to the training center of the Department of industrial engineering of Tsinghua University, the professor of Qinghua University told us about it. Equipment manufacturing industry is a general term for the equipment provided for the national economy and national security

- Q: What functions should be achieved in mechanical structure design?

- Mechanical structure design plays an important role in mechanical design. This chapter mainly discusses the characteristics, steps and mode of thinking of mechanical structure design. The working principle and design requirements of the machine assembly is a major factor in determining the structure and shape of the parts, followed by the selection of materials, manufacturing process requirements, which has the advantages of good manufacturability (processing and assembly). In addition, the perfection of the structure and shape of the parts has a great influence on the strength and stiffness.

Send your message to us

Whole Aluminum Formwork with Different Size with Great Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords