Polypro Eps Insulation Foam Board Wall Siding Companies MS111

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 20000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.Fast construction

2.Self-cleaning and stain resistance

3.Auti-cold and high strength

4.Fireproof

5.Competitive price

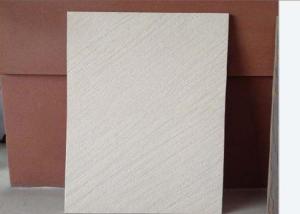

Green Sandstone Wallboard

Our green sandstone wallboard is made of inorganic mortar on the top and ceramic board on the bottom (inorganic resin plate, i.e. fiber cement plate, also called calcium silicate board, is optional for internal wall) with our patented technology and advanced equipment, compounded under low temperature condition. It possesses texture and appearance of natural sandstone, and is free from stain, blackening, moldiness of natural sandstone caused by high water absorption. It is suitable for gluing, wet cladding and dry cladding. | ||

|

| |

Item |

Sandstone Board MS Series | |

Material |

Bottom |

Inorganic resin plate or ceramic plate |

Appearance |

Inorganic facing material | |

Standard Size |

300*600mm*8mm,400*800mm*10mm,600*1200mm*12mm | |

Max Size |

Max Width |

600mm |

Max Length |

1200mm | |

Thickness |

12mm | |

Color |

Dim grey |

MS101 MS102 MS103 MS104 |

Light grey |

MS110 | |

Light yellow |

MS108 MS109 MS111 MS112 MS113 | |

Dark grey |

| |

Silver white |

MS105 MS106 MS107 | |

Chinese red |

MS115 MS114 MS113 | |

Other color customized | ||

Quality Assurance |

Good alkali/acid resistance,durable,easy processed with competitive price | |

Certificate |

CE/CNAS L1257/ MA | |

Technique | Unique technology | |

MOQ |

1000 square meters per model | |

Packing |

Pallet with Wooden Crates and Plastic Shrinked Wrapping | |

Delivery Time |

25-30 days after receipt of the T/T deposit or L/C | |

Mega Wallboard Features

1. Good alkali / acid resistance

2. Good weather resistance (anti-thawing, anti-freezing)

3. Stable dimension, low expansion rate, low contractibility

4. Natural appearance, uniformed

5. Durable, long service life

6. Good stain-resistance, self-clean ability

7. Excellent fire-proof performance

8. Easy to be processed

9. Eco-friendly

10. Easy installation

Performance Indicators of Our Green Wallboards

| Test Item | Quantiy | Industrial Standard | Unit | Test Value | Test Result |

| Size deviation | 10 | Ac=0, Re=2 | Pieces | 0 | Up to Standard |

| Thickness | 10 | ±5 | % | -1.71~-1.5 | Up to Standard |

| Deformation | 10 | Ac1=0, Re'=2 | Pieces | 0 | Up to Standard |

| Edge Straightness | 10 | ±0.5 | % | ±0.2 | Up to Standard |

| Water Absorption | 5 | 0.5<E≤3 | % | Average value:0.5 Single Value: 0.8 | Up to Standard |

| Density | 3 | ≥2.5 | g/cm3 | 2.53~2.54 | Up to Standard |

| Breaking Strength | 7 | ≥7.5mm ≥1000 | N | D>7.5mm 2804 | Up to Standard |

| New Crack Modulus | 7 | Average Value≥30 Single Value≥27 | Mpa | Average value:38 Single Value: 37 | Up to Standard |

| Fire Resistance | 1 | Graded by ABC from High to Low | --- | A1 | Up to Standard |

| Anti-wear | 11 | level and rotation | --- | Level2 / 600r | Up to Standard |

| Resistance to Thermal Shock | 5 | No crack after 10 cycle tests between 145°C~ 15°C | --- | No crack | Up to Standard |

| Resistance to Freezing | 10 | No crack or delamination after 100 cycle tests between 5°C~ -5°C | --- | No crack, no delamination | Up to Standard |

| Moisturized Expansion | 5 | ≤0.06 | % | Average value:0.1 Single Value: 0.02 | Up to Standard |

| Resistance to Acid | 5 | Graded by ABC from strong to weak | Level | A | A |

| Resistance to Alkali | 5 | Graded by ABC from strong to weak | Level | A | A |

| Resistance to Stain | 5 | Classfied as level 5-level1 from the degree of pollution | Level | 5 | 5 |

| Radioactivity | 2 | A class decoration materials: Ira ≤1.0, Ir ≤1.3 | --- | Ira=0.4 Ir=0.8 | A |

Application

1.Outdoor systems:exterior walls of new buildings or renovated projects

2.European/American style architectures,high-end villa walls or roofs

3.Large public construction projects such as office building,commercial podium,etc

4.High environmental requirement places such as surgery room,clean room,pharmaceutical and food production workshop wall.etc.

5.Metro system,railway station,tunnel and other underground projects

6.High quality requirement ceiling

7.Interior decoration wall system

8.Damp places such as kitchen,bathroom,restroom,changing room,etc.

| Australian Sandstone VS Our Sandstone | ||

| Feature | Australian Sandstone | Our Sandstone |

| Texture and Color | Natural color and texture, but big color variation of the Sandstone from different stone mines,installation effect is not uniformed. | Natural color and texture, small color variation of the Sandstone from different boards, installation effect is uniformed |

| Stain resistance | A lot of pinholes make it high water absorption and easy to collect microorganisms, which cause it to darken or get moss, reduce its durability. | The surface is made of Inorganic facing materials,processed by our patented techniques, giving it good self-clean and stain-resistance capacity and durability |

| Installation | After cutting into boards, it's sandy and smooth,making it not suitable for gluing for safety concerns, but high cost for dry cladding. | Our Sandstone board is made of Inorganic facing material compounded with ceramic composited plate as a base. The embossed base is strong, and suitable for gluing |

| Environment | Severe damage to the natural environment during the mining process. | No damage to the Nature as it is not exploited from stone mines |

| Price | High price due to the high cost of mining and low yield rate. | Money efficient and affordable due to mass production and lower comprehensive cost |

- Q: Do you have a foam sandwich board where there is no fire hazard?

- JGJ130-2011 construction construction fastener type steel pipe scaffolding safety technical specifications I have

- Q: Is polystyrene a polycyclic aromatic? Is not all the hydrocarbon chemical products are carcinogenic, such as the production of foam raw materials: polystyrene

- In the installation of two wall can be removed after the wall) → third, four-step large bar and a small bar → with a bar → then pole → plus scissors support → shop Scaffolding (yuan extension fastener steel scaffolding erection sequence)

- Q: The main characteristics of extruded polystyrene foam board XPS extruded board

- Construction road and reinforced processing shed included in safe and civilized construction fee?

- Q: What kind of material to build a house insulation ah

- Composite pipe refers to the use of two or more triode according to a certain law combination, equivalent into a transistor, composite tube, also known as Darlington tube

- Q: Lushi foam board how much money a square, there is the spot?

- Seek construction site safety technical information (all). The more detailed the better! The The The The The

- Q: EPS insulation board SPS insulation board what is the difference

- Ventilation ducts are generally metal pipes are also fiberglass or other materials of the pipeline, the pipes are hard material, the fan running when the skeleton refused to pull the agent off the biased floor vibration, if there is no soft connection, the vibration will be through the hard material ventilation Pipeline pass very far, the formation of noise pollution

- Q: GB requirements for b1 grade extruded plate oxygen index?

- It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate

- Q: My home security windows installed when the wall is found in the insulation layer, the expansion of the bolt into the wall after they have pulled out, fixed, how can we make the expansion bolt into the wall insulation layer touch whip sniper Biao riveting riveting fixed and stuffed into the brick wall to fix the effect as well. More

- From the process it To overcome the EPS board complex production process, with EPS board can not replace the superior performance. It is made of polystyrene resin and other additives through the extrusion process has a continuous uniform surface and closed-cell honeycomb structure of the plate, the honeycomb structure of the thick plate, there is no gap, this closed-cell structure Insulation materials can have different pressures (150-500Kpa) at the same time have the same low value of the thermal conductivity (only 0.028W / MK) and enduring excellent insulation and compression performance, compressive strength up to 220-500Kpa.

- Q: Pp plus pulley slide with aluminum alloy which is better?

- Rigid waterproof casing is a steel pipe plus a wing ring (steel plate made of the ring on the steel pipe), installed in the wall (mostly concrete wall), for a sudden ridicule Guji nine consultative pipe through the wall, Wall waterproof; flexible waterproof casing in addition to the external wing ring, the internal file ring and the like, the flange wire, there are sets to sell, but also their own processing, for the need for shock absorber, such as water pumps When the pipe is connected to the wall

- Q: The outer wall of the pre-sprayed real stone paint, the existing cracks seepage, and now spray rain rainbow good Shi 120 can effectively waterproof it?

- Mainly to the security of the Ministry of Education, the two sides of the costume Tuo fat Taibo abundance archives, equipment acceptance records, civilized construction measures, but thirteen boxes of security information is too cumbersome, that is to be simplified, and now there is no simplified.

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | South America20.33% Africa 2.32% Mid East 3.39% Eastern Asia 4.64% Central America 2.14% Northern Europe 5.14% Domestic Market 62.04% |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou,Shenzhen |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polypro Eps Insulation Foam Board Wall Siding Companies MS111

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 20000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords