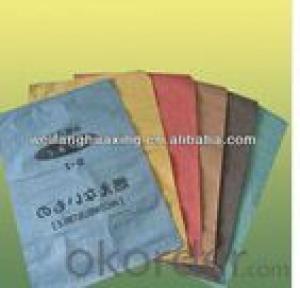

virgin material pp woven bags 50kg

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Material: | pp | Industrial Use: | feed grade | Feature: | Moisture Proof |

| Surface Handling: | Offset Printing | Sealing & Handle: | Top heat cut | Custom Order: | Accept |

| Place of Origin: | BEIJING China (Mainland) | Brand Name: | CMAX | Model Number: | CMAX |

| type: | pp bag | color: | white/red/yellow/pink/and other color | trade term: | FOB,CIF. |

| packing: | 1000pcs/bale | payment: | T/T | moq: | 11.5ton |

| delivery time: | 20-25days | Customer order: | Accept | Top: | Heat cut |

Packaging & Delivery

| Packaging Detail: | packing:1000pcs/bale |

| Delivery Detail: | 25-30days |

Specifications

manufacture for more than 15 years

two large factories in China and one large factory in Cambodia

60 tons daily capacity.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- I did, I saw, salted duck, beef and other good packaging, is the use of the former.

- Q: What is the material for edible fungus stick packing bag?

- HDPE bags, which are not high temperature resistant, can be sterilized at 104 degrees. Over this temperature, the contamination rate of pathogens will be increased.

- Q: What kind of material is the urea packing bag made of?

- Polypropylene (Polypropylene) is a semi crystalline thermoplastic (PP). With high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid base corrosion.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q: What kind of material is the food packing bag in general?

- Now the standard of living has improved, basically the food vacuum packed bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What material is the packing bag for pure milk, please?

- Lining, Xiong Xiaoli. Study on the separation of aluminum plastic paper composite packaging. Packaging engineering, 2008, 29 (12): 56-58.lixixiao2 (in TA) food grade polyethylene chen.1fan (TA station) composite layer of aluminium metal and linear PE, the middle layer there should be consistent with FDA zznjut (station link TA) composite and 100% more than one layer of polymer should be PE, the rest of the aluminum foil paper, duanyanjian (station TA) aluminum composite paper plastic bag

- Q: Dried fish vacuum packaging packing bag can not puncture

- Anti piercing vacuum packaging bags, first of all, choose the material of the bag to have toughness, followed by the thickness of the bag

- Q: What about the table of nutrition values on food packages?

- Since each manufacturer may have different sizes of "one", it is better to use 100 grams or 100 milliliter units when comparing the nutrients in a similar product. Quantity of heatHeat is often listed in thousands of joules, and, where possible, the least calorie products should be selected. ProteinIs the total protein content in the food, G is the unit of measurement.

- Q: Plastic packing bag printing color

- See what you do with materials, PE/PP/PET, etc., the material is not the same, the price is different, this is usually the printing press to help you determine what material to use.

- Q: What are the types of composite packaging bags?

- Folding containerA large volume of transport package, the weight of more than 1 tons. The top of the container is usually equipped with metal hangers or rings, which is convenient for lifting and transporting of forklifts or cranes. When discharging, it is possible to open the discharge port at the bottom of the bag and unload the cargo conveniently. Suitable for shipment of granular or powdery articles.Container bags are usually made of polyester fibers such as polypropylene and polyethylene. Because the container loading and unloading of goods, transportation is very convenient, improve handling efficiency, in recent years made shoes soon.

Send your message to us

virgin material pp woven bags 50kg

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords