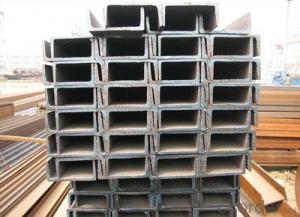

U Channel Steel the Length Thickness According to the Customer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、the details information of our Channel Steel

1)the ordinary model

Height: | 90-400mm |

Thickness: | 9-14.5mm |

Surface: | according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 90*37*4.5mm--400*104*14.5 mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2)the light model

Height: | 90-400mm |

Thickness: | 6.4-8.0mm |

Surface: | Painted or Galvanized;according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 50*32*4.4mm--400*115*8.0mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2、the Product Advantage

1) We can design the channel steel according to customers’requirements

2) We can manufacture under complete quality control system---ISO9001&SGS

3) We can installed with instruction of experienced engineers

4) Easy to assemble and dismantle

5) Eco-friendly material: can be used for several times and can be recycled

6) Shorter construction period, longer using time

7) High strength and stiffness, high weight bearing.

3、why choose us ?Product Advantage

1)The channel steel quality is prime quality

2)Our price is competitive price with our competitor

3)We provide the professional service

4)Prompt delivery & Seaworthy packing

5)Mill Test Certificate

- Q: What are the different types of steel channel connections used in industrial buildings?

- There are several types of steel channel connections used in industrial buildings. Some common examples include bolted connections, welded connections, and moment connections. Bolted connections involve using bolts and nuts to secure the channels together, while welded connections involve joining the channels through welding. Moment connections, on the other hand, are more complex and are designed to resist bending moments in the structure. These connections typically involve additional plates and welding to provide stability and strength.

- Q: The pressure is: 50TLength: 1 meters or soMaterial: steel or steelSpecifications: please tell me how much you can use!Prawns help you ah! Urgent! Online, etc.!

- 50t concentrated force in the middle of the words.500KN x 0.25m=125KNmWx>=125000000/215=581395.3mm3More than [36a or more than 36a components are recommended.

- Q: How do steel channels contribute to the strength of a structure?

- Steel channels contribute to the strength of a structure by providing structural support and resistance against loads. They are designed to distribute weight evenly and efficiently, helping to prevent structural failure and increase overall stability. The shape and design of steel channels allow them to withstand bending, torsion, and shear forces, making them an essential component in constructing robust and durable structures.

- Q: How do steel channels perform in terms of fire resistance?

- Steel channels, also known as steel sections or steel beams, generally have good fire resistance properties. The fire performance of steel channels is influenced by several factors, including the grade and thickness of the steel used, the arrangement of the channels, and the fire protection measures applied. Steel, being a non-combustible material, does not contribute to the spread of fire. However, it does lose its strength at high temperatures. The rate at which steel loses its load-bearing capacity in a fire depends on the temperature and duration of the fire exposure. To enhance the fire resistance of steel channels, various fire protection measures can be applied. The most common method is to encase the steel channels in fire-resistant materials such as concrete or gypsum boards. This encasement acts as a barrier, slowing down the transfer of heat to the steel and providing insulation, thus prolonging the time it takes for the steel to reach critical temperatures. Additionally, steel channels can be coated with intumescent coatings or fire-resistant paints. These coatings expand when exposed to high temperatures, forming a protective layer that insulates the steel and delays its temperature rise. Overall, steel channels, when properly protected, can offer significant fire resistance. However, it is essential to consider the specific fire safety requirements of a structure and consult with fire protection experts or follow applicable building codes and standards to ensure adequate fire resistance measures are implemented.

- Q: What is the maximum length of a steel channel?

- Multiple factors, including manufacturing capabilities, transportation limitations, and intended application, influence the maximum length of a steel channel. Typically, steel channels can vary in length, ranging from a few feet to several hundred feet. Nevertheless, for practical purposes of transportation and handling, the usual threshold is between 40 and 60 feet. If the desired length exceeds this limit, additional measures and specialized equipment may be necessary to transport and install the steel channel at the desired site. To ascertain the specific maximum length of a steel channel for your project, it is vital to consult manufacturers, suppliers, and engineers who specialize in this field.

- Q: How do you calculate the weight of 100 channel steel?

- By multiplying the length, draw the volume of 100 channel, and then multiply by 7850kg/m3, and then get the weight of the channel.

- Q: What are the different fabrication methods for steel channels?

- There are several different fabrication methods for steel channels, depending on the specific requirements and desired outcomes. These methods include hot rolling, cold rolling, press braking, and welding. Hot rolling is the most commonly used method for fabricating steel channels. It involves heating the steel billet or ingot to a high temperature and then passing it through a series of rollers to shape it into the desired channel profile. Hot rolling allows for a wide range of sizes and shapes to be produced efficiently and cost-effectively. Cold rolling is another fabrication method for steel channels, which involves passing the steel through a set of rollers at room temperature. This process can yield channels with precise dimensions and improved surface finish. Cold rolling is typically used for producing channels with tighter tolerances and smoother surfaces. Press braking is a fabrication method that involves bending a flat steel plate into the shape of a channel. It requires the use of a press brake machine, which applies pressure to the plate to achieve the desired channel profile. Press braking is often used for producing custom or non-standard channel shapes where hot or cold rolling may not be suitable. Welding is a fabrication method that involves joining two or more steel pieces together to form a channel. This method is commonly used when fabricating channels with complex shapes or when modifications need to be made to existing channels. Welding can be done using various techniques such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, or arc welding. Overall, the choice of fabrication method depends on factors such as the required channel dimensions, tolerances, surface finish, and the complexity of the desired shape. Each method has its advantages and limitations, and it is important to select the most appropriate method based on the specific requirements of the project.

- Q: Can steel channels be used in rooftop installations?

- Indeed, rooftop installations can utilize steel channels. In the realm of construction, steel channels are frequently employed due to their robustness and resilience. In the context of rooftop installations, steel channels serve numerous functions, encompassing support for solar panels, HVAC units, and other equipment. Notably, they furnish a stable and dependable foundation for these installations, effectively enduring the weight and strain associated with rooftop applications. Additionally, steel channels can be tailor-made and manufactured to meet specific needs, ensuring effortless installation on rooftops. In summary, steel channels prove themselves to be a dependable and pragmatic option for rooftop installations.

- Q: Can steel channels be used in framing systems?

- Indeed, framing systems can incorporate steel channels. Steel channels, also referred to as C-channels or U-channels, are frequently employed in construction and framing endeavors. Their versatility lies in their ability to offer structural support and stability to the framing system. In both residential and commercial buildings, steel channels are commonly utilized as studs, joists, and beams. Their remarkable load-bearing capacity enables them to endure substantial loads and forces. Furthermore, steel channels possess durability, fire resistance, and resistance to rot, pests, and decay, rendering them a trustworthy option for framing systems.

- Q: How do steel channels perform under impact loads?

- Steel channels exhibit excellent performance when subjected to impact loads. Their ability to effectively absorb and distribute impact energy, coupled with their structural design and material properties, minimizes the risk of damage or failure. The structural shape of steel channels, featuring flanges and web, contributes to their increased stiffness and rigidity, thereby enhancing their capacity to withstand impact loads. Furthermore, the utilization of high-strength steel in the manufacturing process of steel channels further improves their resistance to impacts. This guarantees that steel channels can resist deformation and maintain their structural integrity even when exposed to significant impact forces. In conclusion, steel channels are a dependable choice for applications where impact loads are a concern as they offer a high level of performance, ensuring the safety and durability of structures or systems.

Send your message to us

U Channel Steel the Length Thickness According to the Customer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords