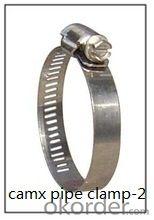

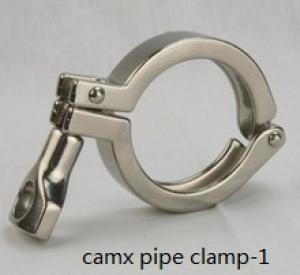

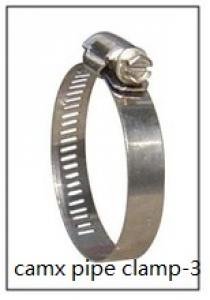

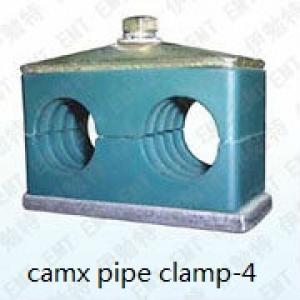

two screw rubber pipe clamp for cars

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Usage: Pipe Clamp

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

- Q: Can the 5 (20) A meter withstand the current of 30A?

- 5 (20) A stands for this meter, allowing long running currents not exceeding 20A, instead of representing 20A for a short period of time. As for the meaning of that 5, nor is it representative of the rated current, but should be called the reference current. It is a benchmark used in the inspection and test of electric meters, such as detecting the light load of electric meters. The full load。 Starting current. And so on, that's the percentage of this 5A. For example, when the current reaches 1% of 5A, it can measure accurately, and achieve the standard of accuracy, such as measuring the accuracy of the meter under the ratio of 1%, 10%, 50%, 70%, 100%, etc. of 5A. As a reference, this parameter is meaningless to the user.

- Q: Why is the air compressor leakage gap will open?

- Check which parts of the internal and external machines are faulty. First, disconnect the inside and outside lines so that you can determine which part of the problem is.

- Q: How to use the correct measuring clamp current meter

- Using the graphic method of current clampClamp meter AC DC current measurementClamp meter measuring voltage clamp meter surge current measurement

- Q: How to maintain and maintain the communication and power room?

- 1, multimeter. As one of the necessary testing tools in the daily maintenance, the multimeter is mainly used for testing voltage, current, frequency and other related parameters, requiring the resolution of at least 41/2 bits (10000 words). At present, the maintenance personnel is usually used by the American FLUKE company F80, F180 series of high precision digital multimeter, the multimeter resolution can reach 44/5 (50000 words), can fully meet the "Regulations" on the accuracy of the measurement requirements. At the same time, this kind of multimeter with anti dropping, anti burning, antimagnetic, anti sputtering, intelligent alarm and good maintenance, very suitable for field use.

- Q: How to measure the current and voltage clamp meter?

- The jaw open press wrench clamp meter on the side of the test line is placed in the jaw jaw central, will be closed.

- Q: How to test the current on a motor?

- String into the known small resistance, take the resistance on the pressure drop, memory oscillograph to record the waveform, and then converted to the current value.If an electric current clamp is used, the current clamp is certainly possible, but it is necessary to understand the proportional relationship between the current clamp and the transmitted signal.Resistance sampling is simple and practical.

- Q: Is there a caliper meter that can measure direct current?

- Magnetic balance type current sensor called compensation sensor, namely the primary current Ip generated in the magnetic core premises through a secondary magnetic field coil current magnetic field generated by the compensation, the compensation current of Is accurately reflect the current of primary side Ip, so that the Holzer device is in the working state of zero magnetic flux detection.

- Q: To measure current, how many transformers are used in 0-100A? How big is the ammeter? How do I get the S1'S2 line?

- Transformer 100/5 can wear from L1 to L2 in S1S2, the current meter, S2 connected current meter after grounding. Note! This is not salty. Current mutual open short circuit without. If open may breakdown or transformer, and the main loop arc

- Q: What is the connection between the distribution box and the bridge?

- May and the use of electric welding machine, wire welding machine in which a random metal pipe, when welding welding current welding wire through a plurality of left back, in a weak point there will be a great current, have a fever.

- Q: Does this universal meter measure the output current of a direct current welder?

- The clamp type meter measures current by measuring current with a current transformer. The DC current cannot produce an alternating magnetic field, so the clamp type meter cannot measure the direct current.

Send your message to us

two screw rubber pipe clamp for cars

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords