Unisource Packaging Tape - Tissue Tape Double Sided Hot Melt Adhesive 90micron Black Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

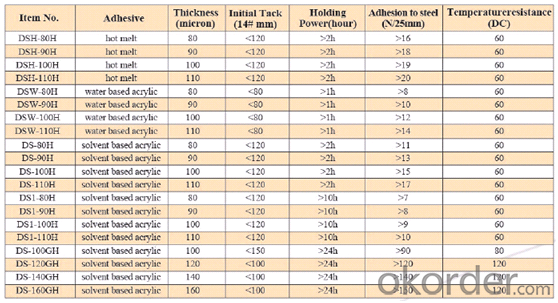

Typical Physical Reports of Double Sided Tissue Tape

Packaging Detail

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing PVC pipes?

- No, packaging tape is not suitable for sealing PVC pipes. It is designed for securing packages and does not provide the necessary strength and durability to effectively seal PVC pipes.

- Q: What are the considerations for using packaging tape on fragile items like ceramics?

- When using packaging tape on fragile items like ceramics, there are several considerations to keep in mind. Firstly, it is important to choose a tape that is specifically designed for fragile items, such as a tape with reinforced fibers or cushioning properties. This will provide extra protection and prevent damage during transit. Secondly, it is crucial to apply the tape carefully, ensuring that it is not too tight or too loose. Applying the tape too tightly can put pressure on the fragile item and potentially cause it to crack or break, while applying it too loosely may result in inadequate protection. Additionally, it is advisable to use multiple layers of tape for added strength and stability. Lastly, labeling the package as fragile can help alert handlers to exercise caution when handling the package. Overall, taking these considerations into account will help ensure the safe transportation of fragile ceramics.

- Q: Can packaging tape be used for sealing wooden crates?

- Yes, packaging tape can be used for sealing wooden crates. It provides a strong and secure bond, ensuring that the crate remains sealed during transportation or storage. Packaging tape is designed to adhere to various surfaces, including wood, making it an effective choice for sealing wooden crates. However, it is important to consider the weight and size of the crate before solely relying on packaging tape. For heavier or larger crates, it may be necessary to reinforce the seal with additional methods such as nails or screws.

- Q: Can packaging tape be used for sealing plastic garment bags?

- Indeed, plastic garment bags can be effectively sealed using packaging tape. The primary purpose of packaging tape is to create a reliable and long-lasting seal on diverse materials, such as plastic. By utilizing packaging tape, one can ensure that the plastic garment bag remains tightly sealed, thereby safeguarding the garments inside from dust, moisture, and other harmful substances. This, in turn, prevents any potential damage or dirtiness. Furthermore, packaging tape is typically user-friendly, as it can be effortlessly cut with a dispenser or a pair of scissors, which adds to its convenience when sealing plastic garment bags.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. Packaging tape is specifically designed to securely seal packages, providing protection against tampering, moisture, and damage during transit. It is strong, durable, and often features a strong adhesive backing that creates a long-lasting seal. When applied properly, packaging tape can effectively secure packages containing high-value contents, ensuring their safe delivery. However, it is important to consider additional security measures, such as using tamper-evident tape or adding extra layers of protection, depending on the value and fragility of the contents.

- Q: A tape of 2.5 cm thick, about how many meters

- If the thickness is 2.5 50mic transparent tape. Then there are about 155 meters (3mm tube). Measured by actual measurements

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: Does packaging tape come in different textures?

- Yes, packaging tape does come in different textures. While the most common type of packaging tape is smooth and glossy, there are also textured variations available. Some examples of textured packaging tape include rubberized tapes, which have a soft and grippy texture, and paper-based tapes, which have a rougher texture similar to masking tape. These textured tapes are often used for specific purposes, such as providing extra grip or adhering to difficult surfaces. However, it's important to note that textured packaging tapes may have different adhesive properties and may not be suitable for all applications.

- Q: Can packaging tape be used for sealing documents or important papers?

- Packaging tape is not typically recommended for sealing documents or important papers. While it may provide a temporary solution in certain situations, it is not designed for this specific purpose. Packaging tape is primarily used for securing packages and boxes during transportation, and its adhesive properties may not be suitable for delicate papers or documents that require long-term protection. Additionally, using packaging tape on important papers may leave behind residue or damage the paper itself. It is advisable to use specialized document sealing products, such as document envelopes or archival folders, which are designed to provide proper protection and preservation for important papers.

- Q: Which kind of sealing tape is solvent resistant?

- High temperature tapes are solvent resistant. Aluminum foil tape adopts high quality pressure-sensitive adhesive, good adhesion, strong adhesion, anti-aging and other effects

Send your message to us

Unisource Packaging Tape - Tissue Tape Double Sided Hot Melt Adhesive 90micron Black Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords