Tinplate For Kitchenware, SPCC/MR, Secondary Grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

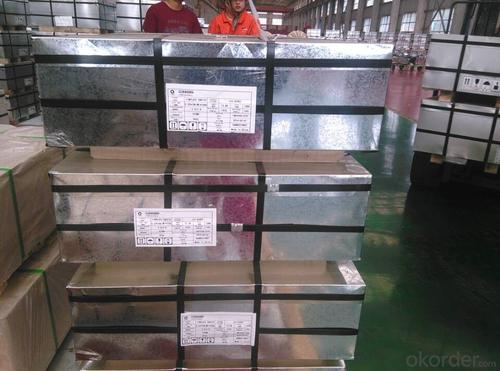

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: How does tinplate contribute to the overall protection of packaged products?

- Tinplate contributes to the overall protection of packaged products by providing a durable and corrosion-resistant barrier. This helps to prevent contamination, spoilage, and damage from external factors such as moisture, oxygen, light, and microorganisms. Tinplate also offers excellent heat resistance, ensuring the integrity and safety of the packaged products during transportation, storage, and usage.

- Q: What are the main regulations governing tinplate recycling?

- The main regulations governing tinplate recycling include waste management laws and regulations, environmental protection guidelines, and recycling policies. These regulations aim to ensure proper disposal and recycling of tinplate materials, minimize environmental impact, and promote sustainable waste management practices. Additionally, there may be specific regulations related to the handling, collection, and processing of tinplate materials to ensure safe and efficient recycling operations.

- Q: What are the different types of tinplate surface treatments?

- The different types of tinplate surface treatments include electrolytic tinplate (ETP), tin-free steel (TFS), and blackplate.

- Q: How does tinplate perform in terms of tamper resistance?

- Tinplate performs well in terms of tamper resistance. Its strong and durable nature makes it difficult to tamper with or manipulate without leaving visible signs of tampering. Additionally, tinplate can be sealed tightly, making it hard for unauthorized individuals to access the contents without clear evidence of tampering.

- Q: Is tinplate affected by moisture or humidity?

- Yes, tinplate is affected by moisture and humidity. Moisture and high humidity levels can cause tinplate to corrode and rust over time. It is important to store and handle tinplate in dry conditions to prevent any potential damage.

- Q: How to open cans

- A tin can be opened, the handle is separated, and the canned fruit can be clamped by the head, and the rotating knob and the tin can be opened. Remember, when you turn the knob, you can only rotate clockwise and turn counterclockwise clockwise.

- Q: How does tinplate packaging contribute to product freshness?

- Tinplate packaging contributes to product freshness by providing a hermetically sealed and protective barrier against external elements such as moisture, air, and light. This helps to preserve the quality, flavor, and aroma of the product over a longer period of time, ensuring that it reaches consumers in its original state. Additionally, tinplate packaging is resistant to corrosion, preventing any potential contamination that could compromise the freshness of the product.

- Q: How does tinplate compare to other packaging materials?

- Tinplate offers several advantages over other packaging materials. It is highly durable, providing excellent protection for the contents. It is also resistant to corrosion, ensuring the integrity of the packaging even in harsh conditions. Tinplate is lightweight and easy to handle, making it cost-effective in terms of transportation and storage. Additionally, it is eco-friendly as it is 100% recyclable. Overall, tinplate is a versatile and reliable packaging material that outperforms many others in terms of strength, longevity, and sustainability.

- Q: How does tinplate contribute to the overall stackability of packaging?

- Tinplate contributes to the overall stackability of packaging due to its high strength and rigidity. It provides stability to the packaging structure, preventing it from collapsing or deforming when stacked. Additionally, tinplate's smooth and flat surface allows for better alignment and interlocking of packages, ensuring a stable and secure stack.

- Q: What are the causes of tinplate rusting and how to prevent them?

- Attachment of impurities. The impurity is mainly caused by the difference of the impurity with the iron sheet, or the impurity adsorbed the water on the iron sheet to form a galvanic cell.

Send your message to us

Tinplate For Kitchenware, SPCC/MR, Secondary Grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords