Tin Sheet Cutting Machine Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set carton set

- Supply Capability:

- 1000 Sets per Month day set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

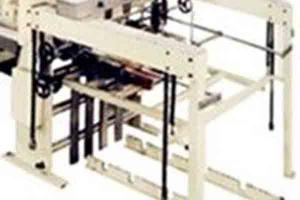

Tin Sheet Cutting Machine Manufacturer

This tin sheet cutting machine is used to cut tinplate ,silicon steel and other metal with high accuracy and high efficiency,

1.Main technical parameter:

Applying range |

Thickness of plate: 0.14-0.5

Width of plate: 40-1050mm |

Production capacity |

1.6metre/second |

Type of Moto | Y90L-6 |

Rotate speed |

940/min |

Power consumption |

1.1kw |

Size |

15oo ×1100 ×1200mm |

weight |

About 1000kgs |

2.Main application:

This Tin sheet cutting machine is applied to cut tinplate ,silicon steel and other metal with high accuracy and high efficiency, it's the necessary equipment in tin can making factory. This machine also include a knife sharpener to sharpen the knife and a handle to adjust cutting size at any time.

- Q: What are the materials for the nut locating pin of the spot welder?

- Hello, at present, most of the domestic KCF material, foreign exchange has now been made of silicon nitride ceramic, and now I mainly do the silicon nitride welding pin this

- Q: What's the difference between a spot welder and an electric welder?

- Spot welding machine is heated by the current welding parts itself, so that its contact parts after melting, cooling, welding, welding machine through the current heating solder or welding rod and welding parts to melt welding. The iron is heated by the electric current, the resistance wire is heated and transmitted to the iron head, and the soldering head is contacted with the welding piece and the solder to melt and finish the welding.

- Q: Working principle of spot welding machine

- The electrode and the weldment are respectively connected with the two output terminals of the power supply. When welding begins, contact the welding rod and the weldment first. At this time, the power supply is short circuited, and the current flowing through the contact is very large. Moreover, the contact surface of the electrode and the weldment is coarser, but only a few points of contact are in fact, and the contact resistance is large, so that the contact place produces great heat. The electrode is further removed, so that the electrode and weldment have a certain clearance.

- Q: Can ring transformers be used as spot welders?

- The theory is OK, but the ring transformer power is too small to be suitable, and it is recommended to use E transformer or C type transformer

- Q: What is the reason that the battery spot welding stick together after welding?

- Preload time is short, the normal spot welding machine is first press and then discharge, if not pressed on discharge, will certainly stick electrode.

- Q: What is the mean to turn ratio in spot welding machine?

- Primary turns ratio of main transformer coil.

- Q: Can spot welders be mobile?

- Mobile spot welder is available, but not many people use it. Safety is a very important problem

- Q: What is the cause of no welding current in AC spot welder?

- Is there something wrong with your trigger circuit?

- Q: Is the smoke from the spot welding machine poisonous when it is welded?

- Some, leading to infertility, killing sperm.

- Q: Can I use a battery as a spot welder? How to do it

- No, the voltage is not enough

1. Manufacturer Overview

| Location | Jiangxi,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | Below US$1 Million |

| Main Markets | South America 1.04 Southeast Asia 3.26 Africa 7.92 Mid East 8.81 Eastern Asia 0.54 South Asia 2.25 Domestic Market 76.18 |

| Company Certifications | Consumer Trustworthy Company;Member of Chiese packaging technology association;Trust-worthy Company |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Tin Sheet Cutting Machine Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set carton set

- Supply Capability:

- 1000 Sets per Month day set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords