Tin Free Steel MR Grade for Oil Can Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tin Free Steel

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3315 and GB/T24180 - 2009 (BS EN 10202:1990) |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | Total chromium min 30mg/m2 max 140mg/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

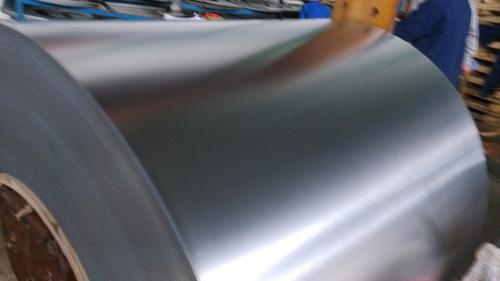

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

- Q: What are the main applications of tinplate in the telecommunications industry?

- Tinplate has several main applications in the telecommunications industry, including the production of high-frequency cables and connectors, as well as the shielding of electronic components. Due to its excellent conductivity and corrosion resistance, tinplate is widely used in telecommunications infrastructure to ensure reliable signal transmission and protect sensitive equipment from electromagnetic interference.

- Q: What are the main applications of tinplate in the cosmetics industry?

- Tinplate is extensively used in the cosmetics industry for packaging purposes. It is commonly employed for manufacturing containers such as cans, jars, and tubes for various cosmetic products like creams, powders, lip balms, and hair care products. Tinplate provides excellent protection against moisture, light, and other external factors, ensuring the longevity and quality of the cosmetic products. Additionally, its malleability allows for intricate designs and attractive branding possibilities, making it a popular choice in the cosmetics industry.

- Q: How to distinguish galvanized plate and tin plate

- General galvanized sheet used in home appliances and electronics industry, thicker. Tin plate, tinplate, used in packaging industry, thinner.

- Q: Tinplate also known as what? What is the density of it?

- This kind of galvanized steel in a long time Chinese called "tin", some people think that the tin plate when the manufacture cans from Macao (English Macao for tinplate imports, readable) so called "tin".There are other statements, such as China used this lamp tin plate made of kerosene, shaped like a horse, so called "tin".

- Q: Can tinplate be used for packaging pet care products?

- Yes, tinplate can be used for packaging pet care products. Tinplate is a durable and food-safe material that can effectively protect and preserve various products, including pet care items, such as pet food, treats, and grooming products. Additionally, tinplate packaging offers excellent resistance to corrosion and can be easily shaped and decorated to enhance product appeal.

- Q: Are there any specific regulations for tinplate in different countries?

- Yes, there are specific regulations for tinplate in different countries. These regulations typically cover aspects such as the composition and quality standards of tinplate, labeling requirements, and safety guidelines for its production, use, and disposal. Each country may have its own set of regulations or may adopt international standards for tinplate. It is important for manufacturers and importers to comply with these regulations to ensure the safety and quality of tinplate products in the respective countries.

- Q: How does tinplate perform in terms of odor and taste retention?

- Tinplate is known for its excellent odor and taste retention properties. It forms a protective barrier that prevents any transfer of odors and flavors between the packaging material and the contents. This makes tinplate a preferred choice for packaging sensitive food and beverage products, ensuring that their quality and taste remain intact.

- Q: Can you tell me how to deal with the recycling of tinplate?

- The tin is magnetic, is easy to recycle scrap. Second, waste tin as scrap iron and steel melted, make steel containing a small amount of tin (less than 0.1%), to improve the performance of cast iron.

- Q: Can tinplate be used for packaging products with sensitive electronic components?

- Yes, tinplate can be used for packaging products with sensitive electronic components. Tinplate is known for its excellent electrical conductivity and corrosion resistance, making it an ideal choice for protecting sensitive electronic components from external factors such as moisture and oxidation. Additionally, tinplate offers good mechanical strength and can be easily formed into various shapes, providing secure packaging for these components.

- Q: What are the safety regulations for using tinplate in food packaging?

- The safety regulations for using tinplate in food packaging vary depending on the region and country. However, generally, tinplate used in food packaging must meet strict standards set by regulatory bodies such as the Food and Drug Administration (FDA) in the United States or the European Food Safety Authority (EFSA) in Europe. These regulations typically cover factors such as the composition of the tinplate, its resistance to corrosion and leaching, and its suitability for contact with different types of food products. Manufacturers are required to comply with these regulations to ensure the safety of consumers and the integrity of the packaged food.

Send your message to us

Tin Free Steel MR Grade for Oil Can Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords