Timber Beam Auto-climbing Bracket ACB100 & ACB50

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of ACB100 & ACB50

The power source of hydraulic self climbing form ACB100 is itself the hydraulic jacking system, hydraulic lifting system comprises a hydraulic oil cylinder and the upper and lower reversing box, reversing box can control the lifting guide rail or the lifting frame body, through the hydraulic system can make mutual climb form template frame body and the guide rail, so that the hydraulic self climbing formwork steadily toward climb up, hydraulic self-climbing formwork without other lifting equipment, in the construction process has the advantages of convenient operation, climbing speed, high safety coefficient. Is the high-rise building construction and bridge construction preferred template system. Hydraulic self climbing form is mainly divided into four parts: the template system, embedded system, support system and hydraulic system.

2. Main Features of ACB100 & ACB50

1, hydraulic self climbing formwork can be climbing, also can be single truss-climbing, climbing process is stable, synchronization, security.

2, hydraulic self climbing formwork can be climbed all the way, also be inclined to climb, climb speed.

3, climbing formwork once assembled, has been the top does not fall to the ground, saving the construction site, but also reduces the template (especially the bruise damaged panel).

4, to provide a full range of operating platform, construction units shall not waste materials and labor for re erection of platforms.

5, small error correction structure construction, simple, can pursue layer to eliminate the error of construction.

3. ACB100 & ACB50 Images

4. ACB100 & ACB50 Specification

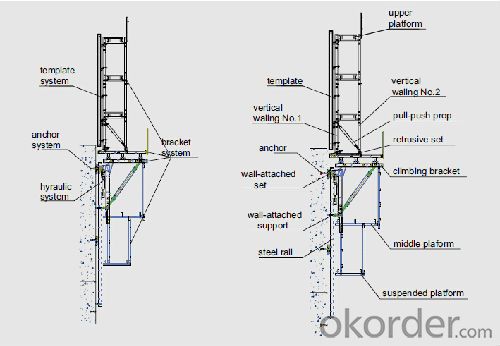

ACB-100 Structure Sketch

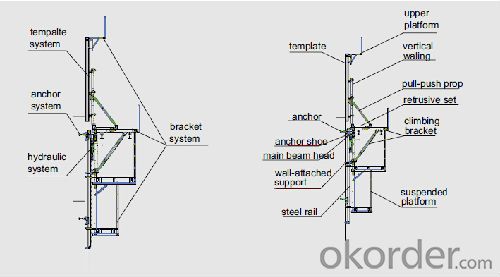

ACB-50 Structure Sketch

5. FAQ of ACB100 & ACB50

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in ACB100 & ACB50, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of ACB100 & ACB50, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- After the shift between the device and the main girder is inserted on the pin and the pin card, after the shift is already used for rear jacking jacking, wind cable is tightened, the adjacent frame between the climbing frame is firmly rachel.

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: The difference between the scaffold and the scaffold

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change: one is the scaffold without turning over shelf, two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

Send your message to us

Timber Beam Auto-climbing Bracket ACB100 & ACB50

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches