Thermal insulation eps sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 kg/m²

- Supply Capability:

- 100000 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

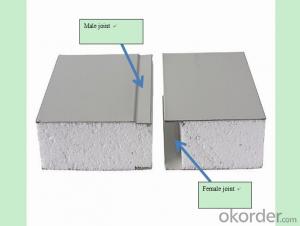

Features of EPS sandwich panel:

1.Our EPS sandwich panel has the following characteristics: light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2. The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3. It is easy to install and can be used many times over.

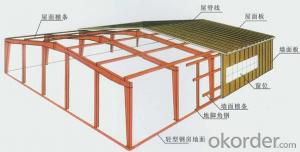

4. Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

Specification:

| Effective width | Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm |

| Length | According to customer's request |

| Materials | Polystyrene foam board(EPS), Color steel sheet |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: polystyrene foam board or polyurethane foam board | |

| Thickness | Color steel sheet: 0.3-0.6mm Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm |

| The polystyrene density | 8-20kg/m3 |

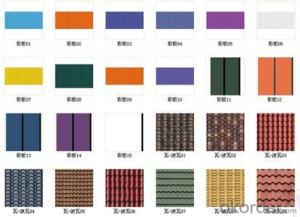

| Color | RAL Standard |

| Character | Light in weight, heat insulation, water resistant, green and environmental |

| Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Extrusion board is different from the foam board, bulk density can not be arbitrarily changed, the technical units to do relatively light But not less than 30kg / cubic meter is generally 35kg / m3 or so manufacturers and manufacturers different

- Q: Reinforced concrete and metal sandwich board how much difference

- Tower crane driver, scaffolding type of work, all kinds of welding workers

- Q: What is the difference between the board and the core board? The The

- Cantilevered scaffolding should use biaxial symmetrical section of the steel, which is usually said I-beam models and anchors need to calculate each other, according to the stairs to set the shape

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: Sandwich panels and Malacca ecological board what is the difference

- Not count But it is best to mark the gun in the obvious place.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask questions.

- Q: Are sandwich panels suitable for retail outlets?

- Sandwich panels, consisting of two rigid layers and a core material, are ideal for retail outlets. With their strength and durability, the rigid layers ensure longevity, while the core material provides insulation and soundproofing. In a retail setting, sandwich panels serve various purposes. They can serve as sleek and modern exterior cladding, enhancing the building's appearance. Additionally, they can be utilized for interior walls and partitions, creating distinct areas within the store. The installation of sandwich panels is effortless, and they can be tailored to meet the specific requirements of the retail outlet. They can be painted or adorned to align with the store's branding and aesthetics. Moreover, their lightweight nature enables easy transportation and assembly, making them a cost-effective choice. The benefits of sandwich panels extend beyond aesthetics. They offer exceptional thermal insulation, ensuring a comfortable shopping experience regardless of the season. This leads to energy savings and a pleasant environment for customers. Ultimately, sandwich panels are a suitable option for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an appealing and functional solution for both the store's exterior and interior.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

Send your message to us

Thermal insulation eps sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 kg/m²

- Supply Capability:

- 100000 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords