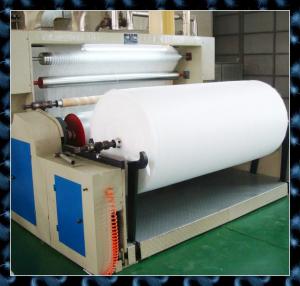

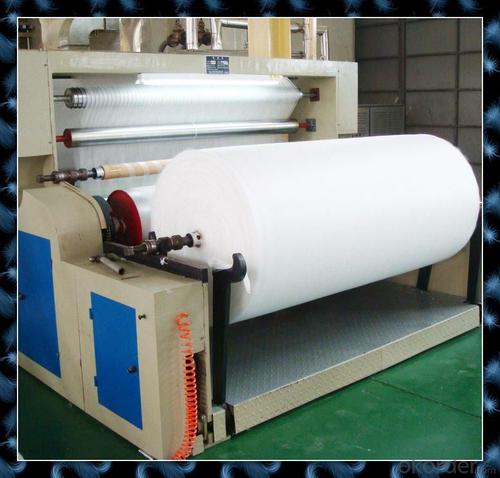

Textile Raw Materials Processing Machinery D

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery ofTextile Raw Materials Processing Machinery D

Packaging Detail: to be packed in seaworthy strong wooden case or carton.

Delivery Detail: about 20days after receipt of the down payment.

Specifications of Textile Raw Materials Processing Machinery D

It is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

Main specification:

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application ofTextile Raw Materials Processing Machinery D

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q: What are the classification of shuttleless looms?

- Rapier loom: with a rigid or flexible rapier head, bring hold, guide weft. Rapier looms in addition to the appropriate weaving plain and texture fabric, which is characterized by easy color change, suitable for multi-color weft fabric for yarn-dyed, double-velvet fabric, terry fabric and decorative fabric production

- Q: How to calculate the density of rapier linen?

- Weft dense wheel and other weft density ÷ 3 × braid number × the number of worms, weft density ÷ 3 × number of teeth = the number of worms equal to the number of Wei dense wheel, each teacher is not the same, but the results are quite different.

- Q: What is easy to soil (soil - releasing)?

- The fabric is in the process of wearing, due to the adsorption of air dust and human excreta and contamination and the formation of dirt

- Q: What is the development of air-jet looms in various countries?

- Now the main representative of the domestic air-jet looms are: Qingdao Hongqi textile machinery JA11A type, spr700 Si Pulan air-jet looms, Xianyang loom GAX and ZA209i type, in the textile machinery GA718 type, Weifang Jinzi JS21N type, Suzhou Textile Machinery ASGA701 Type and so on.

- Q: What is the role of the parchment loom?

- Decisive in the reed that place is generally not light pulp heald frame high arrow arrows with burrs and so on

- Q: How much is the razor loom?

- 1, the fabric of the latitude and longitude interweaving more, playing the greater the resistance of the fabric, should use the earlier opening time, when the warp warp crossing angle, the weft angle is also large, so weft displacement, Small, suitable for weaving tight fabric. On the other hand, when the opening is later (less comprehensive), the warp beam warps the weft angle is small, the weft has the retreat, the weft insertion area is increased, and the thin fabric is suitable for weaving.

- Q: What is the principle of textile machine?

- The The shuttleless locomotive speed is high, usually 4-8 times faster than the shuttle loom, so the large area of the application of shuttleless loom, can greatly improve labor productivity.

- Q: How high is the efficiency of towel rapier looms?

- Rapier weaving speed is relatively slow 150-200RPM, variety adaptability, less investment, cheap accessories.

- Q: What is the difference between a textile and a woven fabric?

- The woven fabric is made of yarns of two systems arranged vertically and longitudinally and longitudinally, and woven on a loom according to a certain regularity. There are denim, brocade, linen and so on.

- Q: What is the difference between air-jet looms and water-jet looms for weft storage?

- Adapt to different varieties, relatively single water spray, jet range is relatively wide.

1. Manufacturer Overview

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery D

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords