Tenax TT Geogrids - PVC Coated Polyester Geogrids for Highway with CE Certificates

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

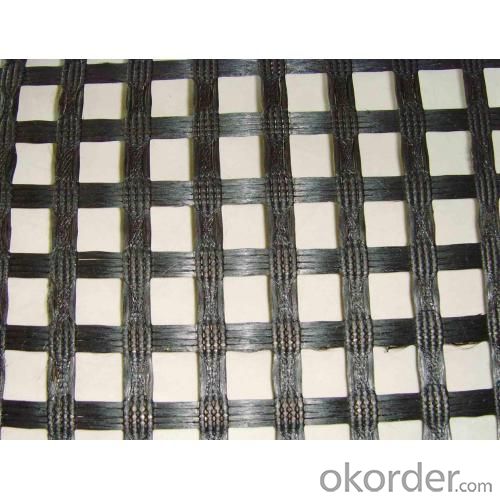

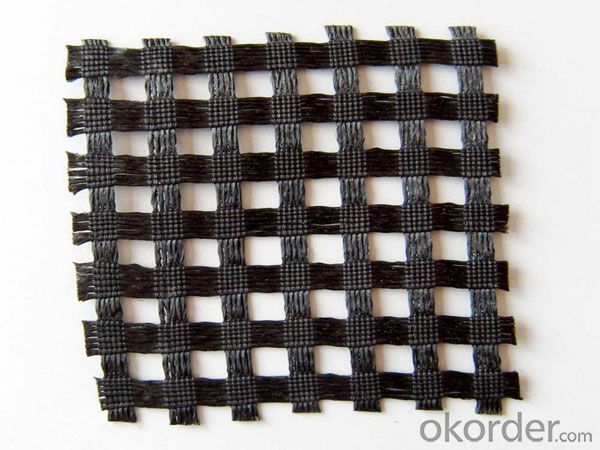

Structure of Pvc Coated Polyester Geogrids:

Pvc Coated Polyester Geogrids is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.Because of its follow similar compatible principle , the key highlight is composite performance of asphalt mixture .and it fully protects fiberglass base material and significantly improves substrate wearability and shearing ability,thus to strengthen,resist cracking road surface wheel rut etc, ending the diseases occurring highway asphalt pavement hard to solve.

Main Features of Pvc Coated Polyester Geogrids:

fiberglass geogrid for soil reinforcement

- Reinforcement of the surface of road and bridge.

High tensile strength, low elongation

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

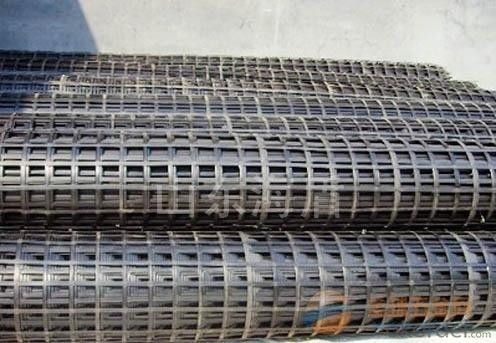

Pvc Coated Polyester Geogrids Images

Pvc Coated Polyester Geogrids Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they provide reinforcement to the soil, enhancing its stability and load-bearing capacity. This allows for the construction of structures on weak or challenging soils that would otherwise require expensive excavation or additional materials. Additionally, geogrids help in preventing soil erosion by providing a barrier against the movement of soil particles, reducing the need for costly erosion control measures. Moreover, these grids are lightweight, making them easy to handle and install, saving time and labor costs during construction. Lastly, geogrids have a long lifespan and are resistant to chemical degradation, ensuring their effectiveness and durability over time. Overall, geogrids offer a cost-effective and sustainable solution for improving the performance and longevity of construction projects.

- Q: How do geogrids improve the stability of slopes?

- Geogrids improve the stability of slopes by providing reinforcement and enhancing the overall strength of the soil. They are typically installed within the slope to distribute stress and prevent soil movement, effectively reducing the risk of slope failure. Additionally, geogrids increase the bearing capacity of the soil, allowing for better load distribution and improved stability of the slope.

- Q: Geosynthetic materials for flood control materials

- Such SPE.Shows that a large number of engineering practice, geomembrane impervious good, general permeability coefficient K =10cm/s ~ 10cm/s; has great flexibility and adaptability to deformation ability; have good aging ability, under water, water is more durable. According to the anti aging test, it can be concluded that the service life of the polymer geomembrane buried in soil and water can be up to 50 years, and the service life of the high-density geomembrane in the dam is more than 100 years. Mainly made of geogrid, geogrid, belt, soil gabion, geotextile tube, geotextile bag, Geomat, EPS, geocell and so on, it is used for soil reinforcement and reinforcement. Such as the reinforcement of soft soil foundation, steep slope, retaining structure built in the stable foundation, embankment collapse rescue.

- Q: How do geogrids enhance the load-bearing capacity of pavements?

- Geogrids enhance the load-bearing capacity of pavements by providing reinforcement and stabilization to the soil layers underneath. They distribute and transfer the load from the surface to a wider area, reducing the stress on the pavement and preventing the formation of cracks and deformations. Additionally, geogrids improve the overall structural integrity of the pavement by increasing its resistance to lateral movement and improving its durability.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Because the main force borne by the steel wire, if it is false, the consequences can be disastrous ah!

- Q: What are the factors that affect the long-term performance of geogrids?

- There are several factors that can influence the long-term performance of geogrids. These include the type and quality of materials used in the manufacturing of the geogrid, the installation process and techniques employed, the environmental conditions to which the geogrid is exposed, and the level of maintenance and monitoring provided. Additionally, factors such as load characteristics, soil properties, and the design and construction of the overall geotechnical system can also impact the long-term performance of geogrids.

- Q: How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing stabilization and reinforcement to the soil, leading to a reduction in the amount of excavation and land disturbance required. This helps to minimize the need for additional resources and materials, as well as the overall carbon footprint of the construction project. Additionally, geogrids can enhance the longevity of structures, reducing the need for frequent repairs or replacements, further minimizing the environmental impact.

- Q: The future of geotechnical materials

- steel-plastic composite geogridThe steel plastic geogrid with the high strength steel wire, through the special treatment, and PE, and the addition of other additives, through extrusion to make it into a composite high tensile band, and the surface of the coarse grain, it is high strength reinforced geotextile. The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint.

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- That gap has been covered in tape, then tape the knife more she cut off, finally brush mortar.4, let it dry naturally, and then gently polished.

- Q: Biaxial tension geogrid

- In addition, there are steel plastic grille, fiberglass geogrid and so on

Send your message to us

Tenax TT Geogrids - PVC Coated Polyester Geogrids for Highway with CE Certificates

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords