Table Formwork with Remarkable Quality & Long Time Resuable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

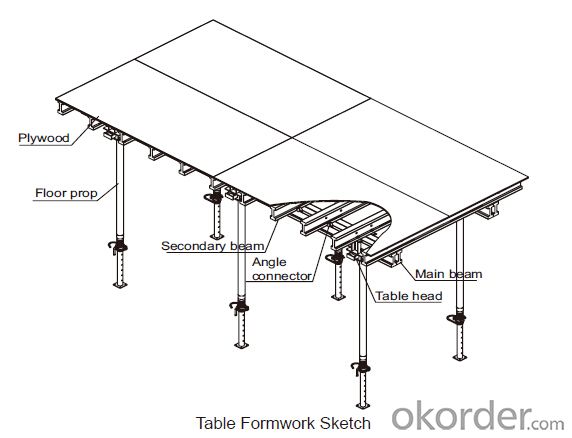

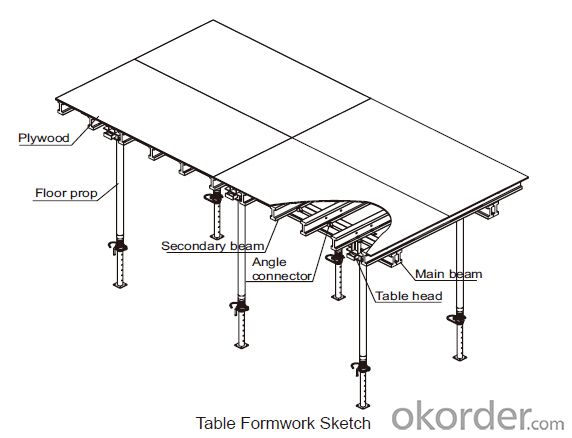

1. Structure of Table Formwork

Table formwork is used for the concrete pouring of wall.

The system has two parts, formwork and pull-push props. The formwork is made of plywood, timber beam and steel waling.

Timber beam formwork is a highly efficient and convenient system for medium area slab project.

High construction efficiency with special system tools.

Lifting fork for lifting the table formwork to upper floor.

Trolley for moving the table formwork on floor.

Flexible application with stand alone props.

2. Main Features of Table Formwork

Safer condition with handrails.

Adjustable radius, flexible application.

For any storey heights and slab thickness.

Easy connection with adjustable steel clamp.

Convenient for construction.

Easy, rapid and economical.

Can choose shoring props or towers according to different loadings and height.

3. Table Formwork Pictures

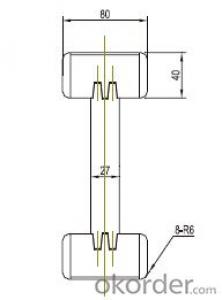

4. Table Formwork Specification

As a standardized system, it is flexible to assemble.

An optimum position of the table gravity point can be achieved by selecting the correct suspension points for the crane

ropes and testing it on site by trail lifts.

The shifting trolley enables you to lower the table from the floor slightly and transport the table horizontally to the next

location easily.

5. FAQ of Table Formwork

What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue..

- Q: What is the use of building wall formwork support? Thank you

- Multicard support beams with multi support beams in visa, visa in early removing system to save 32% than ordinary plywood sold cuplok supporting system construction.

- Q: Technical specification for construction formwork safety JGJ162-2008 who has made me please

- This specification is applicable to the design, manufacture, installation and dismantling of the cast-in-place concrete engineering formwork system in construction.

- Q: 1, JGJ162-2008 construction formwork safety technical specification;2, JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications; the friend has. Send me thanks

- 3 2.1.12 flying die flying shuttering mainly by the platform board, support system (including beam, support, support, legs, etc.) and other accessories (such as lifting and walking mechanism, etc.). The utility model is a large tool type template, which is called a table mould or a table model because of the appearance of the utility model. Because it can take advantage of lifting machinery, pouring from the well under the floor of the lift out of the transfer to the upper layer of repeated use, so called flying mode. 2.1.13 tunnel mode tunnel shuttering a combination of stereotypes template, while pouring concrete wall and floor of the template, because the shape of the template like a tunnel, it is known as the tunnel model.

- Q: 86335 template support, what is the concept of those advantages

- The invention, which is a new type of digital steel formwork support composite structure, will create a rapid development miracle for the construction industry, which can save a lot of wood resources and human resources, and reduce the waste of raw materials. It fully resolved before the support structure defects, installation and disassembly and height adjustment is flexible and convenient, saving labor and material, improve construction quality and reduce construction cost, improve work efficiency, concrete good forming quality, novel and beautiful appearance. By the high praise of the construction sector, the product has broad market prospects, good investment recovery and social benefits.

- Q: Since the building, and I would like to ask some of the basic knowledge to the construction of a unified drawing, plus or minus 0 and the height of the drawings, the roof slope requirements. Now the blue steel reinforced concrete inclined roof beams or do. Here we use multiple beams, and the waterproof, thermal insulation, in tile. Anyway, many shortcomings is wood, attic space basically scrapped, there is a fire started...I would also like to use concrete flat top, that is, do not let, more depressed.If I can use wooden beams, waterproof SBS, hanging plastic extruded board?The construction of plastic extruded board in inclined roof beams hung strong? Construction is not difficult?As well as the 8X11 meters of the roof, 30 degrees slope, sloping roof concrete cost about? I feel modeling and cloth reinforcement are very troublesome, expensive cost estimation

- You can put the beam properly after the play flowers on top, which is the slope of the wall, so that you can

- Q: What is the building template support

- (3) the characteristics of the new steel building formwork support:Features: keel tight flexible connection not only makes the operation simple and easy, and the structure is stable;Features two: retractable keel allows you to be able to adapt to any size; characteristics of the three: the column and the keel is not only simple and more flexible connection;Features four: tie rod light not only save material, and is more flexible and firm, flexible fastener is a must;Features five: compared to the wooden beam structure is more accurate, more solid; characteristics of the six: the construction site is beautiful and clean, greatly enhance the corporate image, highlighting the strength of the enterprise;Features seven: labor, material saving, time saving, more secure; features eight: do not use wood, products can be reused, so that the construction cost is greatly reduced.Building houses are required to achieve a certain level of earthquake, so the general buildings are cast in situ floor and shear wall structure,Formwork supporting composite structure

Send your message to us

Table Formwork with Remarkable Quality & Long Time Resuable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches