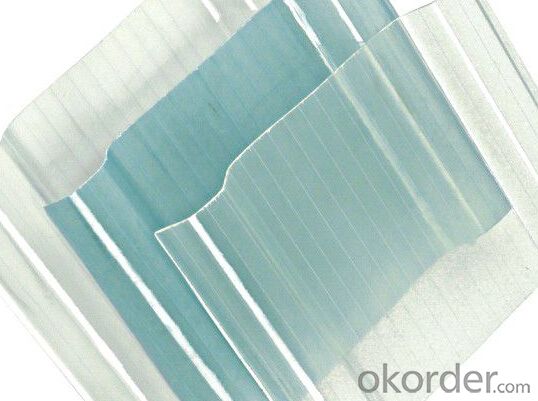

Synthetic resin tile impact resistance low temperature

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage

1. Persistent color

2. Excellent load resistance

3. Sound: Experimental proof

4. Impact resistance, good low temperature resistance

5. Excellent corrosion resistance

6. Excellent thermal insulation properties

7. Excellent self-cleaning performance

8. Stability

9. Excellent waterproof performance

10. Excellent electrical insulation properties

11. Fire resistance

12. Installation is quick

13. Green

Advantages detailed analysis:

1.Color persistence

Synthetic resin tile surface material is the selection of imported super high weather resistant engineering resin produced. In the natural environment with exceptional durability, it is even long-term exposure to ultraviolet light, moisture, heat, cold, poor conditions, can still maintain its color stability. According to the United States from Arizona and Florida and other areas with high sun exposure to outdoor use results show that can ensure ten years color change Delta E = 5. Synthetic resin tile xenon arc weathering test obtained in terms of 450 sunlight samples in different parts of the conclusion.

2.Excellent anti load

Synthetic resin tile has good bearing capacity. In the lower temperature region, even if the roof perennial snow, synthetic resin tile will not produce surface damage and fracture phenomenon. After the test, the support spacing of 660mm, loading 150 kg, tile will not have cracks and damage.

3.Sound insulation effect is good

It is proved that the synthetic resin tile has a good effect on absorbing the noise when it is affected by the external noise such as heavy rain, strong wind and so on.

4.Excellent corrosion resistance

Synthetic resin tile can resist acid, alkali, salt and other chemical substances for a long time. The results showed that there was no chemical reaction in the salt, alkali and acid for 24 hours in the following 60% hours. Very suitable for the use of acid rain prone areas and coastal areas, the effect is particularly significant.

Product Usage:

Wave board is a new type of fashion art interior decoration sheet. Decorative materials are mainly used in hotels, clubs, home decorations, dance halls, resorts, shopping malls, mansions, villas and other renovation works, especially for entry, entrance, backdrop, TV wall, column design, bar, exhibition. Can replace the natural veneer, Tiemian Ban, and so on. There are dozens of patterns, such as pure white board, paste gold, silver, pearl plate, star board, crack lacquer plate, lacquer plate, which makes corrugated cardboard, corrugated board, stone and nearly 30 kinds of effects.

Product Description:

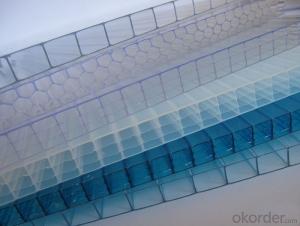

Environmentally friendly synthetic resin tiles are hard PVC plastics and modified ASA resins High weatherability Substrate surface materials are extruded through two extruders, PVC compounded and resin modified ASA materials such as plastic, Or circular wave type water dispenser head into the compound made of double composite plate, and then by a special continuous stereotypes stereotypes, cutting processes, the final color of the green resin for the formation of green ceramic tile products.

- Q: What is the difference between sun panels and plexiglass?

- Sun panels are generally hollow, plexiglass is solid. There is one side of the sun is anti-condensation, one side is anti-ultraviolet. Plexiglass on both sides. Sun panels can be exposed directly to the outside, and plexiglass generally can not accept direct sunlight.

- Q: Which friends know how to remove the plastic film on the sun?

- In the PC sun panels and accessories installed when fixed, it is best to tear the protective film 30mm to 50mm, this is to avoid the accessories to suppress the protective film pressure. But should pay attention to is not too much to expose, or easy to install the operation because of scratching the sun plate.

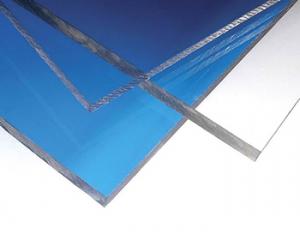

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

- Pull the protective film to see the sheet. Particles or bubbles are relatively small or relatively small, indicating that the recovery of raw materials, but is a good back to the material, this board is the middle grade plate. Such as bubbles and particles more or larger, indicating that the poor raw material, this board is a low-grade plate. If the civilian particles or particles rarely, that the quality of the sun plate is very good, is ten years of quality.

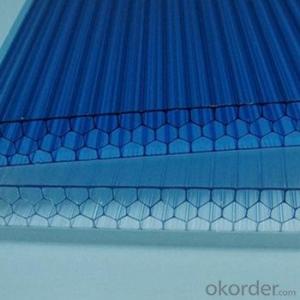

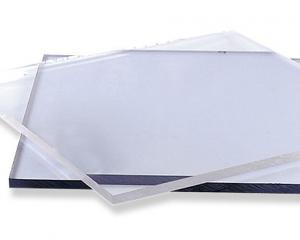

- Q: What is the difference between PC stamina and PC sunboard?

- In fact, from their nickname we can simply distinguish, PC sun plate is also called hollow board, hollow board, as the name suggests is the middle is hollow. PC Nai Liban also known as solid board, of course, is solid.

- Q: What is the difference between a hollow board and a sunboard?

- Sunshine board is one of the lighting board, most of the lighting board is made of FRP and the sun is made of PC (polycarbonate) made, a little PC board warranty period is 10 years and 15 years, The better FRP lighting board warranty period of 20 years, 25 years. Performance comparison, although the thermal conductivity of the lighting board than the sun board is low, but the lighting board is usually a single layer, thermal conductivity than the sun plate. That is the summer sun exposure, then, under the lighting board room temperature to be higher. Light transmittance, carrying capacity under normal circumstances 2 can meet.

- Q: PC sun board life years?

- In fact, the warranty period of the sun board is the warranty of the yellowing index, depending on the UV (UV stabilizer) into the number of cases, under normal circumstances, 50μ UV yellowing index warranty for 10 years

- Q: PC sunshine board, what material, what kind of good

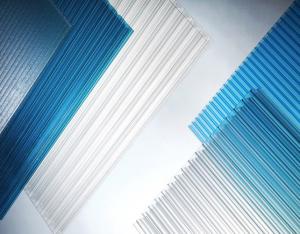

- Hello, the thickness of the sun board is generally 10mm, 8mm, 6mm and other specifications, in the color also has a lake blue, transparent, white and other colors, available to users according to their actual needs and preferences to choose.

- Q: What is the difference between sun panels and lighting panels?

- Material composition description Xining PC sun panels are made of polycarbonate on the surface of a layer of 50um UV UV layer, hollow structure extrusion molding of high-performance lighting materials. Is the most excellent performance of engineering plastics, which has a light, flame retardant, high impact strength, high transmittance, high stability, easy to bend and other characteristics. And is an energy-saving, environmentally friendly materials. Is the preferred material for making lighting materials. FRP lighting board is glass fiber reinforced polyester (FRP lighting board), commonly known as FRP, also known as transparent tile, which mainly by the film, unsaturated resin and glass fiber composition. Frp main material is unsaturated resin, its high strength, flammable, the resin itself is easy to decompose above 50 ℃, poor stability. Resin is chemically synthesized, using styrene solvent, toxic.

- Q: Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- In addition, the thicker the thickness of the polycarbonate PC solar panels, the more layers, the better the insulation performance, but not necessarily the thicker the better, because the PC sheet with the thickness increases, structural complexity, price increases, or to Choose the right one. PC sunshine board during the day cold, night insulation, suitable for greenhouses and other greenhouse lighting insulation use, PC sun panels up to 49% insulation.

- Q: What can I do with my own sunshine board?

- Own balcony sun block rain, balcony sun room, interior partitions can be ah

Send your message to us

Synthetic resin tile impact resistance low temperature

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords