Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

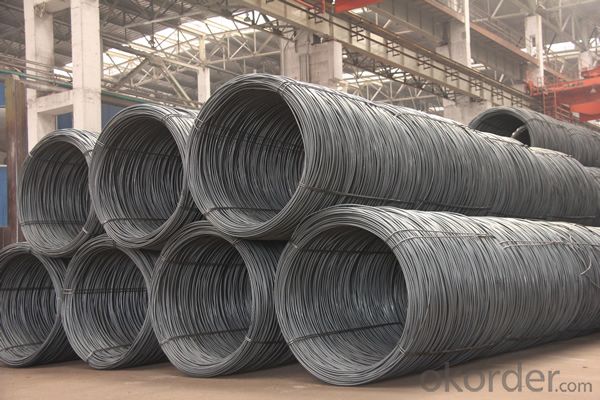

Product Description of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

OKorder is offering Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire are ideal for structural applications and are widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

OKorder's Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire are durable, strong, and wide variety of sizes. They are newly produced by good quality steel billets.

Main Product Features of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

Steel Grade: SAE1006-1018B

Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: in coil, coil weight around 2MT

Alloy or Not: Alloy

Technique: Hot Rolled

Place of Origin: China Mainland

Surface: round, no twisted, light and smooth

FAQ:

Q1: Why buy Hot Rolled Low Carbon Steel Wire Rods for Nails, Steel Wire Mesh from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Packaging & Shipping

plastic film per bundle ,strapped with metal wire and then put into carton box .

- Q: How is steel wire rod used in the manufacturing of wire for solar panels?

- Steel wire rod is used in the manufacturing of wire for solar panels as it provides strength and durability to the wires. The steel wire rod is first drawn into thin strands and then coated with a protective material to prevent corrosion. These wires are then used in the construction of solar panels to connect the photovoltaic cells and carry the electrical current generated by them.

- Q: How is the decarburization of steel wire rod evaluated?

- Various methods and techniques are employed to evaluate the decarburization of steel wire rod, ensuring the final product's quality and properties. Visual inspection is a common evaluation method, whereby the wire rod's surface is carefully examined for signs of decarburization, such as discoloration or scaling. This preliminary assessment offers insights into the level of decarburization. Chemical analysis is also conducted to determine the carbon content at different depths of the wire rod. Samples are taken from various sections of the wire rod and subjected to carbon analysis tests. The results of this analysis reveal the extent of decarburization and aid in assessing its impact on the steel wire rod's mechanical properties. Microscopic examination is a crucial evaluation technique. Metallographic analysis involves preparing thin sections of the wire rod and observing them under a microscope. This allows for a detailed examination of the microstructure, facilitating the identification of any areas affected by decarburization. Specialized equipment, such as image analysis software, can be used to measure the depth and severity of decarburization. Moreover, mechanical testing is performed to evaluate the impact of decarburization on the wire rod's mechanical properties. Tensile strength, hardness, and ductility tests are commonly conducted to assess the wire rod's overall strength and behavior under different conditions. Any significant deviation from the desired mechanical properties may indicate a higher level of decarburization. In conclusion, the evaluation of decarburization in steel wire rod involves a combination of visual inspection, chemical analysis, microscopic examination, and mechanical testing. These techniques provide a comprehensive understanding of the extent and impact of decarburization, ensuring that the wire rod meets the required quality standards and specifications.

- Q: What are the major barriers to entry in the steel wire rod market?

- Several factors contribute to the major obstacles faced by potential new entrants in the steel wire rod market. First and foremost, the substantial capital investment required presents a significant barrier. To establish a steel wire rod production facility, considerable funds must be allocated towards machinery, equipment, and infrastructure. Additionally, the costs associated with procuring raw materials, such as iron ore and scrap metal, further exacerbate the financial burden. This high capital requirement restricts the entry of new players, as they may struggle to secure the necessary funds to compete with established industry participants. Secondly, the steel wire rod market heavily relies on economies of scale. Existing manufacturers benefit from a larger production base, enabling them to achieve cost efficiencies through bulk purchasing, streamlined production processes, and distribution networks. This advantage makes it challenging for new entrants to compete on a cost basis, as they would need to attain similar economies of scale in order to remain competitive. Furthermore, the steel wire rod market is fiercely competitive, with a few dominant players holding significant market share. These well-established companies possess strong brand recognition, longstanding customer relationships, and established distribution channels. Consequently, new entrants face difficulties in gaining market share and diverting customers away from these established players. Regulatory barriers also pose challenges for potential new entrants. The steel industry is subject to numerous government regulations and compliance requirements, including environmental regulations and safety standards. Navigating these complex and costly regulations further adds to the barriers faced by potential new players. Lastly, technological advancements and innovation are imperative for maintaining competitiveness in the steel wire rod market. Existing manufacturers often have access to advanced technology and research and development capabilities, enabling them to produce higher quality products and drive efficiency improvements. New entrants may struggle to match these technological capabilities, making it arduous to gain a competitive edge. In summary, the major barriers to entry in the steel wire rod market encompass high capital requirements, economies of scale, intense competition from established players, regulatory compliance, and technological advancements. These barriers make it challenging for new entrants to infiltrate the market and establish themselves.

- Q: What are the different cleanliness testing methods for steel wire rod?

- There are several cleanliness testing methods for steel wire rod that are commonly used in the industry. These methods help determine the level of impurities and contaminants present on the surface of the wire rod, ensuring its quality and suitability for various applications. Some of the different cleanliness testing methods for steel wire rod include: 1. Visual Inspection: This is the simplest and most basic cleanliness testing method. It involves a visual examination of the wire rod's surface for any visible impurities such as scale, rust, or foreign particles. 2. Magnetic Particle Inspection (MPI): MPI is a non-destructive testing method that uses magnetic fields and iron particles to detect surface and near-surface defects on the wire rod. It is particularly effective in identifying cracks, seams, or other imperfections that may impact the integrity of the wire rod. 3. Eddy Current Testing: Eddy current testing is another non-destructive method that uses electromagnetic induction to detect surface defects and variations in conductivity. It can identify defects such as cracks, pits, or variations in material composition that can affect the wire rod's quality and performance. 4. Ultrasonic Testing: Ultrasonic testing involves the use of high-frequency sound waves to detect internal and surface defects in the wire rod. It can identify flaws such as voids, inclusions, or discontinuities that may compromise the wire rod's structural integrity. 5. Chemical Analysis: Chemical analysis involves the use of various laboratory techniques to determine the chemical composition of the wire rod. It can identify impurities, such as sulfur, phosphorus, or other elements that may affect the wire rod's mechanical properties and corrosion resistance. 6. Microscopic Examination: Microscopic examination involves the use of optical or electron microscopes to magnify the wire rod's surface and analyze it at a microscopic level. It can help identify surface defects, inclusions, or other anomalies that may affect the wire rod's performance. These different cleanliness testing methods for steel wire rod provide valuable insights into the quality and suitability of the material for its intended use. Manufacturers and end-users can utilize these methods to ensure that the wire rod meets the required cleanliness standards and specifications.

- Q: What are the common applications of deformed steel wire rod?

- Deformed steel wire rods have numerous common applications across various industries. Some of the most prevalent applications include: 1. Construction and infrastructure: Deformed steel wire rods are extensively used in the construction sector for reinforcing concrete structures. They are primarily employed in the creation of beams, columns, slabs, and walls to enhance the strength and durability of the concrete. The deformed shape of the wire rod provides enhanced bonding with concrete, making it an ideal choice for construction projects. 2. Manufacturing and industrial sectors: Deformed steel wire rods find application in the manufacturing and industrial sectors for various purposes. They are commonly used in the production of wire mesh, wire ropes, nails, and screws. The deformations on the wire rod surface improve the grip and prevent slippage, making it suitable for manufacturing applications that require strong and reliable fastening. 3. Agricultural and horticultural applications: Deformed steel wire rods are utilized in the agricultural and horticultural sectors for fencing purposes. They are commonly used to create sturdy and durable fences for livestock enclosures, crop protection, and boundary demarcation. The deformations on the wire surface provide additional strength and ensure that the fence remains securely in place. 4. Automotive industry: Deformed steel wire rods are employed in the automotive industry for various applications. They are extensively used in the manufacturing of suspension systems, engine components, and seat frames. The deformations on the wire rod surface enhance the overall strength and rigidity of these components, ensuring better performance and safety in vehicles. 5. Mining and geological applications: Deformed steel wire rods find usage in the mining and geological sectors. They are utilized in the production of support structures such as rock bolts, mesh, and cables for stabilizing underground excavations. The deformations on the wire rod surface help to enhance the gripping capability and resistance to deformation, making it suitable for these demanding applications. Overall, the common applications of deformed steel wire rods span across construction, manufacturing, agriculture, automotive, and mining sectors. The unique properties of deformed steel wire rods, including their high tensile strength, enhanced grip, and durability, make them indispensable in various industries.

- Q: How is steel wire rod used in the production of wire mesh for erosion control?

- Steel wire rod is an essential component in the production of wire mesh for erosion control. The wire rod is first passed through a series of machines to undergo a process called wire drawing, where it is stretched to a smaller diameter and shaped into a long, continuous wire. This wire is then further processed to achieve the desired thickness and strength required for erosion control applications. In the production of wire mesh for erosion control, the steel wire rod is typically woven or welded together to create a mesh structure. The wire mesh acts as a physical barrier to prevent soil erosion by holding the soil in place, especially on sloping terrain or areas prone to water flow. The wire rod's high tensile strength and durability make it an ideal material for erosion control applications. The wire mesh produced from steel wire rod is capable of withstanding harsh environmental conditions, such as heavy rainfall or strong water currents, without deforming or breaking. The wire mesh can be tailored to specific erosion control needs by adjusting the gauge and spacing of the wires. Thicker wires and smaller spacing are used for applications that require higher strength and stability, such as retaining walls or embankments. On the other hand, thinner wires and wider spacing may be suitable for less demanding erosion control situations, such as stabilizing soil on residential properties or landscaping projects. Overall, the use of steel wire rod in the production of wire mesh for erosion control provides a reliable and long-lasting solution to prevent soil erosion. Its versatility allows for customization based on specific project requirements, ensuring effective erosion control measures are implemented in various applications.

- Q: What are the common applications of spring steel wire rod?

- Spring steel wire rods have a wide range of applications due to their unique properties. Some common uses include manufacturing springs, wire forms, clips, fasteners, and mechanical components such as shafts and pins. They are also used in the automotive industry for suspension systems, seat frames, and engine components. Additionally, spring steel wire rods are utilized in the construction industry for reinforcing concrete, as well as in the manufacturing of various tools and equipment.

- Q: How is steel wire rod used in the manufacturing of suspension springs?

- Steel wire rod is used in the manufacturing of suspension springs as it provides the necessary strength and durability required to withstand the weight and impact of a vehicle. The wire rod is typically coiled and then formed into the desired shape, creating a resilient and flexible component that can absorb shocks and vibrations while maintaining stability and support in the suspension system.

- Q: What are the main factors affecting the formability of steel wire rod?

- The main factors affecting the formability of steel wire rod include the composition and quality of the steel, the temperature at which the forming process takes place, the speed and force applied during forming, and the presence of any impurities or defects in the material. Additionally, the diameter and shape of the wire rod, as well as the lubrication used during forming, can also influence its formability.

- Q: How are steel wire rods used in the production of wire ropes for ships?

- Steel wire rods are used as the primary material in the production of wire ropes for ships. These rods are first drawn into wire strands, which are then twisted together to form a strong and durable rope. The wire ropes are essential for various applications on ships, such as lifting heavy loads, mooring, and anchoring. Their strength and flexibility make them ideal for withstanding the harsh conditions at sea and ensuring the safe and efficient operation of ships.

Send your message to us

Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords