Steel Pieces Slit From Steel Plate Sheet with Small Width

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Pieces Slit From Steel Plate Sheet with Small Width Description:

Steel pieces slit from steel plate sheet with small width is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel pieces slit from steel plate sheet with small width is usually made of structural steel and is used in construction and civil engineering. The steel pieces slit from steel plate sheet with small width resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel pieces slit from steel plate sheet with small width theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel Pieces Slit From Steel Plate Sheet with Small Width:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

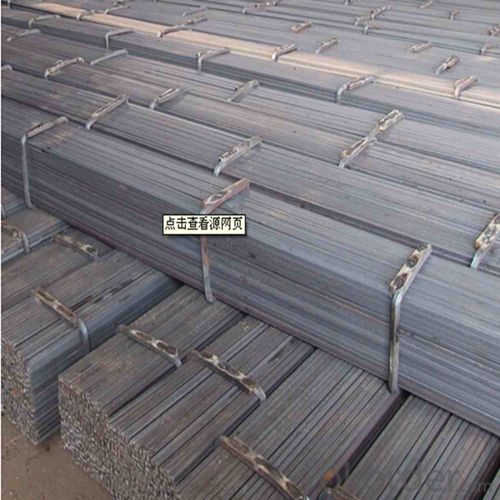

3. Steel Pieces Slit From Steel Plate Sheet with Small Width Images:

4. Steel Pieces Slit From Steel Plate Sheet with Small Width Specification:

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Are steel flat bars suitable for fabrication of brackets or supports?

- Yes, steel flat bars are suitable for the fabrication of brackets or supports. Steel flat bars offer excellent strength, durability, and stability, making them ideal for providing structural support and stability for various applications. They can be easily shaped, welded, and manipulated to create brackets or supports that can withstand heavy loads and provide reliable support in different industries or construction projects.

- Q: Can steel flat bars be used for elevator shafts or doors?

- Indeed, elevator shafts or doors can utilize steel flat bars. The strength and durability of steel flat bars make them a common choice for construction and fabrication projects. When it comes to elevator shafts and doors, it is crucial to employ materials that can withstand heavy loads, offer structural integrity, and ensure passenger safety. Steel flat bars possess these desirable characteristics, which is why they are frequently employed in the construction of elevator shafts and doors. By fabricating and welding them, the necessary framework and support for elevator systems can be created. Moreover, steel flat bars can be coated or treated to increase their resistance to corrosion, rendering them suitable for both interior and exterior elevator applications.

- Q: Are steel flat bars suitable for handrail applications?

- Yes, steel flat bars are suitable for handrail applications. They are strong, durable, and can be easily shaped and welded to meet the specific requirements of handrails. Additionally, steel flat bars offer a sleek and modern aesthetic, making them a popular choice for handrail designs.

- Q: How do you prevent bending or sagging of steel flat bars during installation?

- There are several measures that can be taken to prevent bending or sagging of steel flat bars during installation: 1. Handle the steel flat bars with care during transportation and installation to avoid deformations and bending. 2. Store the steel flat bars in a dry and flat area to prevent exposure to excessive moisture or uneven surfaces that can cause rusting and bending. 3. Ensure adequate support for the steel flat bars throughout the installation process by using appropriate clamps, jigs, or supports to hold them in place and distribute the load evenly. 4. Use the correct fastening techniques and materials, such as bolts, screws, or welding, to securely fasten the steel flat bars and resist bending or sagging. 5. Avoid exceeding the recommended load or weight capacity of the steel flat bars to prevent stress and deformation. Consult professionals if needed to determine the appropriate load limits for your specific application. 6. Regularly inspect the steel flat bars during and after installation to identify any signs of bending or sagging and promptly address any issues to prevent further damage. By following these preventive measures, you can minimize the risk of bending or sagging of steel flat bars during installation, ensuring their long-term structural integrity.

- Q: Are steel flat bars available in different profiles?

- Different profiles are available for steel flat bars, referring to their shape or design. Some common profiles include square edge, round edge, and chamfered edge. Square edge flat bars have sharp corners and straight edges, making them suitable for a variety of applications in construction, manufacturing, and fabrication. Round edge flat bars have rounded corners and edges, providing a smoother and safer finish. They are often used for architectural purposes or in industries where safety is a concern. Chamfered edge flat bars have beveled edges, giving them a more aesthetically pleasing appearance and making them easy to handle. These various profiles offer versatility and can be customized to meet specific project requirements.

- Q: Can steel flat bars be used for making power tools?

- Power tools can definitely be made using steel flat bars. Steel, known for its robustness and endurance, is frequently employed in the production of power tools due to its strength and capacity to endure high temperatures and heavy loads. The flatness of the bars permits effortless shaping and cutting, rendering them appropriate for various power tool parts, including blades, handles, and frames. Furthermore, steel flat bars can undergo additional processing techniques like heat treatment or coating to enhance their performance and resistance against wear and corrosion. In conclusion, steel flat bars are a versatile material that can be effectively employed in the manufacturing of power tools.

- Q: How to determine the application direction of steel grid plate

- The width of the groove generally refers to the length of the steel grid (including the required width of the groove), and the width of the steel plate along the longitudinal direction of the groove

- Q: What is the maximum length of a steel flat bar?

- The length of a steel flat bar can differ based on various factors like the manufacturing process, available resources, and transportation restrictions. Generally, steel flat bars are commonly found in standard lengths between 6 to 12 meters (20 to 40 feet). These lengths are frequently chosen for their convenience in handling, storage, and transportation purposes. In certain situations, it is feasible to produce or obtain longer steel flat bars, but their availability may be limited and necessitate special arrangements for handling and transportation.

- Q: What are the common defects found in steel flat bars?

- Some common defects found in steel flat bars include surface imperfections such as scratches, pitting, and scaling. These defects can occur during the manufacturing process or during handling and transportation. Another common defect is warping, which can happen due to uneven cooling or improper storage. In addition, steel flat bars may have variations in dimensions such as width, thickness, and length, which can be considered defects if they fall outside the specified tolerances. It is important to inspect steel flat bars for these defects before using them in construction or other applications to ensure structural integrity and quality.

- Q: How do you determine the corrosion resistance of a steel flat bar?

- There are several methods available to determine the corrosion resistance of a steel flat bar. One commonly used method involves conducting corrosion tests, such as salt spray testing or immersion testing. In salt spray testing, the flat bar is exposed to a controlled environment of saltwater mist to simulate corrosive conditions. Regular inspections are then conducted to identify any signs of corrosion or degradation. Another approach is immersion testing, where the flat bar is submerged in a corrosive solution for a specific period. The choice of solution depends on the intended application, with examples including acidic solutions like sulfuric acid or alkaline solutions like sodium hydroxide. The flat bar is examined for any indications of corrosion or changes in appearance. Electrochemical testing techniques, such as potentiodynamic polarization or electrochemical impedance spectroscopy, can also be employed. These methods involve applying a controlled electrical current to the flat bar and measuring the resulting electrochemical response. By analyzing the data obtained, corrosion resistance parameters such as corrosion potential and corrosion current can be determined. Furthermore, it is crucial to consider the composition and surface treatment of the steel flat bar. Different alloys and surface coatings can significantly impact corrosion resistance. Factors like the presence of corrosion-resistant elements such as chromium, as well as the application of protective coatings like galvanization or painting, can enhance overall corrosion resistance. In conclusion, an accurate assessment of the corrosion resistance of a steel flat bar requires a combination of laboratory testing, electrochemical techniques, and consideration of the steel's composition and surface treatment.

Send your message to us

Steel Pieces Slit From Steel Plate Sheet with Small Width

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords