Steel Equal Angle with Good Quality 160mm*160mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Steel Equal Angle with Good Quality 160*160mm

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m and 12m

3. Sizes:

| Size(mm) | Mass(kg/m) | Size(mm) | Mass(kg/m) |

| 160*160*10 | 24.729 | 160*160*14 | 33.987 |

| 160*160*12 | 29.391 | 160*160*16 | 38.518 |

Packaging & Delivery of Steel Equal Angle with Good Quality 160*160mm:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

-Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

-Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 1 to 2 months.

Q4: How many tons per bundle?

A4: Around 2-3tons

Q5: How many tons can be loaded into one 20ft container?

A5: Around 23—25tons(6m)

Q6: How many tons can be loaded into one 40ft container?

A6: Around 23—25tons(12m)

Q7: How to avoid the rust after deliver the goods to the loading port?

A7: We will keep the goods at the port covered with water-proof material

Production flow of Steel Equal Angle with Good Quality 160*160mm:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

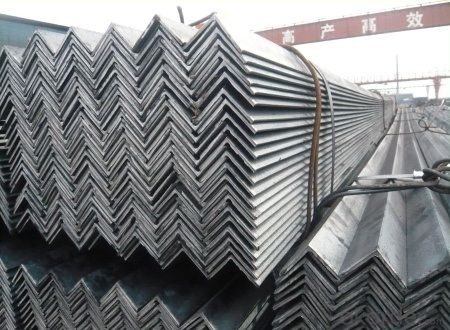

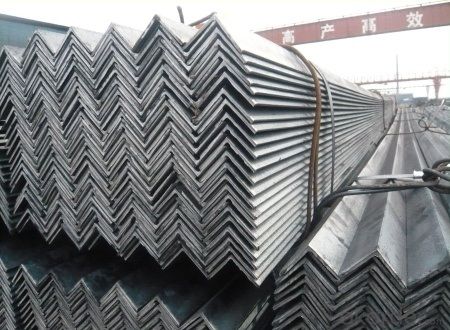

Images of Steel Equal Angle with Good Quality 160*160mm:

- Q: How do steel angles contribute to the sustainability of transportation systems?

- Steel angles contribute to the sustainability of transportation systems in several ways. Firstly, steel angles are widely used in the construction of infrastructure such as bridges, highways, and railway tracks. These structures have a longer lifespan and require fewer repairs and replacements compared to other materials, resulting in reduced maintenance costs and resource consumption. Moreover, steel angles are highly durable and resistant to harsh weather conditions, ensuring the longevity and safety of transportation systems. This durability minimizes the need for frequent repairs or replacement, reducing the overall environmental impact and carbon emissions associated with transportation infrastructure. Additionally, steel angles have a high strength-to-weight ratio, allowing for the design of lighter and more fuel-efficient vehicles. By using steel angles in the manufacturing of automobiles, trains, and ships, the weight of these vehicles can be reduced, leading to improved fuel efficiency and reduced greenhouse gas emissions during operation. Furthermore, steel angles can be easily recycled at the end of their life cycle. Steel is one of the most recycled materials globally, with a recycling rate of over 85%. Recycling steel angles not only reduces the demand for virgin steel production but also saves energy and reduces greenhouse gas emissions associated with the extraction and manufacturing processes. Overall, the use of steel angles in transportation systems contributes to their sustainability by promoting durability, reducing maintenance needs, improving fuel efficiency, and enabling efficient recycling. These factors collectively help to minimize the environmental impact and enhance the long-term viability of transportation infrastructure.

- Q: Are steel angles suitable for balcony construction?

- Yes, steel angles are suitable for balcony construction. Steel angles are commonly used in construction due to their strength and durability. They provide excellent support and stability, making them ideal for balcony construction. Steel angles can withstand heavy loads and are resistant to weathering and corrosion, making them a reliable choice for outdoor structures like balconies. Additionally, steel angles can be easily customized and fabricated to meet specific design requirements, allowing for flexibility in balcony construction. Overall, steel angles are a popular and suitable choice for balcony construction due to their strength, durability, and versatility.

- Q: How are steel angles used in construction?

- Steel angles have a wide range of applications in construction. They serve as important elements for providing structural support and reinforcement in buildings and other structures. Their primary function is to establish strong and stable connections between various components, including beams, columns, and trusses. The framework of a structure is typically formed using steel angles, which offer stability and strength. They can be utilized to create corners, support beams, and brace walls. Moreover, steel angles are commonly employed in the construction of lintels. These horizontal supports are placed above doors and windows to evenly distribute the weight of the structure and prevent any sagging. Apart from their structural purposes, steel angles can also contribute to the aesthetic appeal of a building. They can be used to create decorative edging or trim, enhancing the visual attractiveness of the structure. Additionally, steel angles can be employed in the construction of staircases, handrails, and other architectural features. In summary, steel angles are indispensable and versatile components in the field of construction. They fulfill crucial roles by providing structural support, reinforcement, and aesthetic elements. As a result, they ensure the durability, stability, and visual appeal of buildings and other structures.

- Q: How does the weight of a steel angle affect its load-bearing capacity?

- The weight of a steel angle does not directly affect its load-bearing capacity. The load-bearing capacity of a steel angle is determined by its dimensions, material strength, and design factors such as the shape and support conditions. However, a heavier steel angle may indicate a higher material density, which could potentially result in increased load-bearing capacity if all other factors remain constant.

- Q: What are the load-bearing capacities of different steel angle sizes?

- The load-bearing capacities of different steel angle sizes vary depending on several factors such as the material grade, the angle size, and the length of the angle. Generally, larger steel angle sizes have higher load-bearing capacities compared to smaller sizes. To determine the load-bearing capacity of a specific steel angle size, it is crucial to consider its moment of inertia, which is a measure of its resistance to bending. The moment of inertia increases with the size of the angle, resulting in higher load-bearing capacities. Additionally, the yield strength of the steel used in the angle also plays a significant role in determining its load-bearing capacity. Yield strength is the maximum stress that a material can withstand without permanent deformation. Steel angles with higher yield strength are capable of carrying heavier loads. It is important to consult engineering resources such as steel design manuals or structural engineers to obtain accurate load-bearing capacity information for different steel angle sizes. These resources provide tables and formulas that consider the specific dimensions and properties of the angle to calculate the maximum allowable load it can bear safely. In conclusion, the load-bearing capacities of different steel angle sizes depend on various factors including the angle size, material grade, and yield strength. Consulting reliable engineering resources is necessary to obtain accurate load-bearing capacity information for specific steel angle sizes.

- Q: Can steel angles be used as bracing elements?

- Indeed, steel angles have the capability to serve as bracing elements. Construction and engineering projects frequently employ steel angles due to their robustness and longevity. These angles are commonly utilized to furnish structural support and stability, including as bracing elements. A rigid and secure bracing system can be established by either bolting or welding steel angles to other structural components. The design of these angles, with their L-shape, facilitates easy attachment to other members, thus imparting additional strength and resilience against lateral forces like wind or seismic loads. In summary, steel angles are a dependable choice for bracing elements across a wide range of applications, encompassing buildings, bridges, and industrial structures.

- Q: Are steel angles suitable for vehicle ramps?

- Indeed, steel angles prove to be a fitting option for vehicle ramps. Renowned for their strength and durability, these steel angles are frequently employed in construction. Offering a robust and steadfast surface, they provide an appropriate selection for vehicle ramps. Furthermore, steel angles allow for effortless welding or bolting, enabling the creation of personalized ramp designs that cater to specific needs. In essence, steel angles present a dependable and pragmatic solution for the construction of vehicle ramps.

- Q: Are steel angles prone to warping or twisting?

- No, steel angles are not prone to warping or twisting due to their structural stability and strength.

- Q: Can steel angles be used for agricultural buildings or barns?

- Yes, steel angles can be used for agricultural buildings or barns. Steel angles are commonly used in construction due to their strength and durability. They are particularly useful in agricultural buildings or barns where the structure needs to withstand heavy loads and harsh weather conditions. Steel angles can be used for framing, bracing, and reinforcing various components of the building, such as walls, roofs, and doors. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, making them a versatile choice for agricultural buildings or barns.

- Q: What are the different surface treatments for steel angles?

- There are several different surface treatments available for steel angles, each designed to enhance their durability, appearance, and resistance to corrosion. Some of the common surface treatments for steel angles include: 1. Hot-dip galvanizing: This process involves immersing the steel angles in a bath of molten zinc, which forms a protective coating on the surface. Galvanizing provides excellent corrosion resistance and is ideal for outdoor applications where the angles may be exposed to moisture and harsh weather conditions. 2. Powder coating: Powder coating involves applying a dry powder paint to the surface of the steel angles. The angles are then heated, causing the powder to melt and form a smooth, durable coating. Powder coating provides a wide range of color options and improves the angles' resistance to chipping, scratching, and fading. 3. Electroplating: Electroplating involves depositing a layer of metal onto the surface of the steel angles through an electrochemical process. Common metals used for electroplating include zinc, nickel, and chrome. Electroplating provides both aesthetic appeal and enhanced resistance to corrosion. 4. Priming and painting: Priming and painting involves applying a layer of primer followed by a coat of paint to the steel angles. Priming helps improve adhesion and provides a smooth surface for the paint to adhere to. Painting not only enhances the appearance of the angles but also provides some protection against corrosion. 5. Anodizing: Anodizing is typically used for aluminum angles rather than steel, but it can also be applied to steel. This process involves creating an oxide layer on the surface of the angles by subjecting them to an electrolytic process. Anodizing improves the angles' corrosion resistance, hardness, and color stability. It is important to choose the appropriate surface treatment for steel angles based on the specific application and environmental conditions they will be exposed to. Each treatment offers unique benefits in terms of corrosion resistance, aesthetics, and durability, so carefully considering these factors will help ensure the longevity and performance of the steel angles.

Send your message to us

Steel Equal Angle with Good Quality 160mm*160mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords