Stainless Steel Sheets 304 from China With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

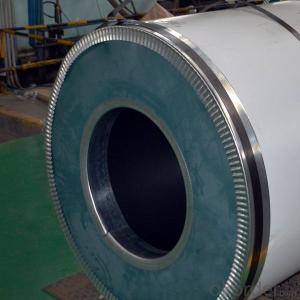

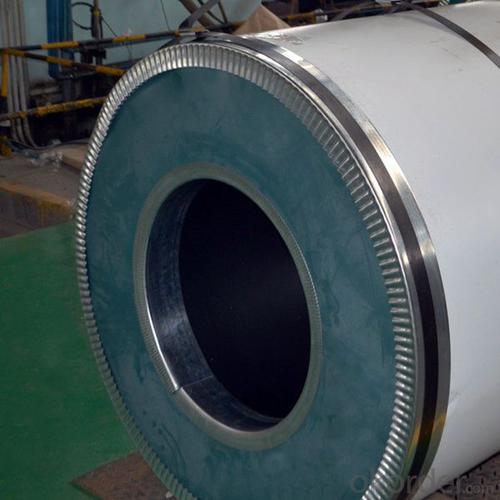

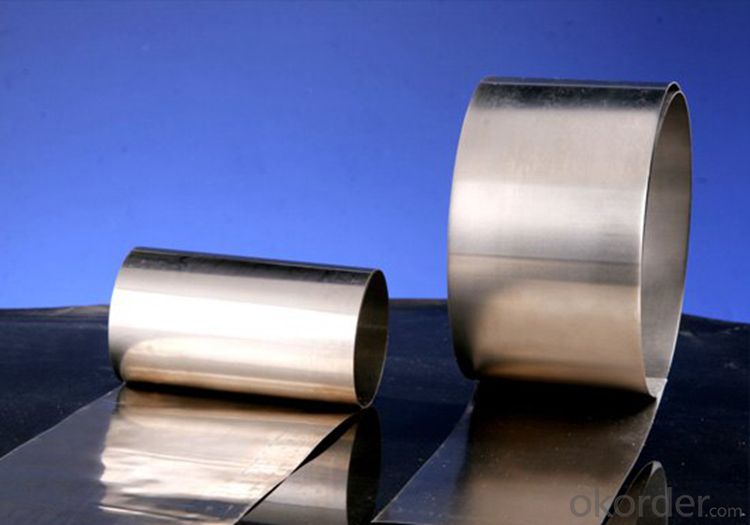

Detail picture for Stainless Steel

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the different surface finishes available for stainless steel sheets?

- There are several different surface finishes available for stainless steel sheets, each offering unique characteristics and aesthetics. 1. No.1 Finish: This is the most common and widely used finish for stainless steel sheets. It has a rough, dull appearance with visible grain lines. No.1 finish is obtained by hot rolling the stainless steel and is suitable for applications where a rough finish is acceptable. 2. No.2B Finish: This finish is obtained by cold rolling the stainless steel and then annealing it, resulting in a smooth, reflective surface with a slightly dull appearance. It is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. No.2D Finish: Similar to No.2B finish, No.2D finish is achieved by cold rolling and annealing the stainless steel. However, it has a smoother and shinier appearance, making it suitable for applications requiring a more polished look. 4. No.3 Finish: Also known as a brushed finish, No.3 finish is achieved by polishing the stainless steel with abrasive belts or brushes. It has a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. No.4 Finish: This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than No.3 finish. It has a more refined and smoother appearance, often used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. No.8 Finish: Also known as a mirror finish, No.8 finish is achieved by polishing the stainless steel with progressively finer abrasive materials until a highly reflective surface is obtained. It provides a glossy, mirror-like appearance, ideal for architectural and decorative applications. 7. Hairline Finish: Hairline finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are some of the most common surface finishes available for stainless steel sheets. The choice of finish depends on the desired aesthetics, functionality, and application requirements.

- Q: Are stainless steel sheets suitable for elevator buttons?

- Yes, stainless steel sheets are suitable for elevator buttons. Stainless steel is a durable and corrosion-resistant material, making it an ideal choice for elevator buttons that are frequently touched and exposed to various environmental conditions. Additionally, stainless steel has a sleek and modern appearance, making it aesthetically pleasing for elevator buttons.

- Q: Can stainless steel sheets be used in food processing industries?

- Yes, stainless steel sheets are commonly used in food processing industries due to their excellent corrosion resistance, hygiene, and durability. The smooth and non-porous surface of stainless steel makes it easy to clean and maintain, ensuring sanitary conditions. Additionally, stainless steel is resistant to chemicals and can withstand high temperatures, making it suitable for various food processing applications such as equipment, storage tanks, and work surfaces.

- Q: What stainless steel can be used instead of galvanized sheet?

- Galvanized sheet can be replaced by 201 stainless steel.

- Q: Can stainless steel sheets be used for brewery equipment?

- Yes, stainless steel sheets can be used for brewery equipment. Stainless steel is a popular choice for brewery equipment due to its corrosion resistance, durability, and hygienic properties. It is resistant to the chemicals and acids commonly used in brewing processes and does not react with beer, ensuring the taste and quality of the final product. Stainless steel sheets can be used to fabricate various brewery equipment such as fermentation tanks, bright tanks, mash tuns, hot liquor tanks, and piping systems. Additionally, stainless steel is easy to clean and maintain, making it an ideal material for brewery equipment where sanitation is crucial.

- Q: Are stainless steel sheets resistant to caustic soda?

- Yes, stainless steel sheets are generally resistant to caustic soda. Caustic soda, also known as sodium hydroxide, is a highly corrosive substance, but stainless steel is known for its excellent corrosion resistance. Stainless steel contains chromium, which forms a protective oxide layer on the surface of the metal, preventing it from reacting with caustic soda. However, it is important to note that the exact resistance of stainless steel to caustic soda may vary depending on the grade or type of stainless steel. Therefore, it is always recommended to consult the specific material specifications or consult with a qualified professional to ensure the appropriate choice of stainless steel for specific applications involving caustic soda.

- Q: Can stainless steel sheets be used in food processing applications?

- Yes, stainless steel sheets can be used in food processing applications. Stainless steel is a commonly used material in the food industry due to its corrosion resistance, durability, and hygienic properties. It is easy to clean and maintain, making it suitable for food processing equipment such as countertops, work surfaces, and storage containers.

- Q: 304 stainless steel plate 1*1219*C what do you mean?

- Roll thickness 1 mm, width 1219 mm, length is unlimited (depending on volume weight). 304 stainless steel is a kind of the most commonly used, law-abiding.

- Q: Are stainless steel sheets suitable for outdoor sculptures or artwork?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or artwork. Stainless steel is known for its exceptional durability, corrosion resistance, and weather resistance, making it a perfect choice for outdoor installations. It can withstand harsh environmental conditions such as rain, snow, UV rays, and temperature fluctuations without losing its structural integrity or aesthetic appeal. Moreover, stainless steel can be easily shaped, cut, and welded, offering great flexibility for artists and designers to create intricate and complex sculptures. Additionally, stainless steel has a sleek and modern appearance, which can add a contemporary touch to any outdoor setting. Its low maintenance requirements and ability to retain its original finish for an extended period make it a cost-effective choice for outdoor sculptures or artwork. Therefore, stainless steel sheets are an excellent material option for creating long-lasting and visually appealing outdoor artworks.

- Q: What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- Stainless steel sand blasting plates are painted on stainless steel sand blasting plates. Stainless steel sand blasting plate refers to the use of zirconium beads through the mechanical equipment in the stainless steel plate processing, so that the surface of the board presents small beads, grainy sand surface, forming a unique decorative effect. Stainless steel sand blasting decorative board uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities decoration and other stainless steel products.

Send your message to us

Stainless Steel Sheets 304 from China With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords