Stainless Steel Sheet Price 309 3mm thickness ba finished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Specifications about stainless steel sheet

Commodity | China supplier 3mm thickness ba finished stainless steel sheet price 309 |

Grade | 201,202,304,304L,316,316L,317L,310S,321,904L,409s,410,430 |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.3-100mm or as customer’s requirement |

Width | 500-3000mm or as customer’s requirement |

Length | 1000-6000mm or as customer’s requirement |

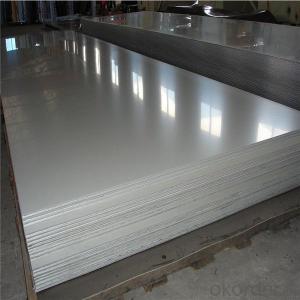

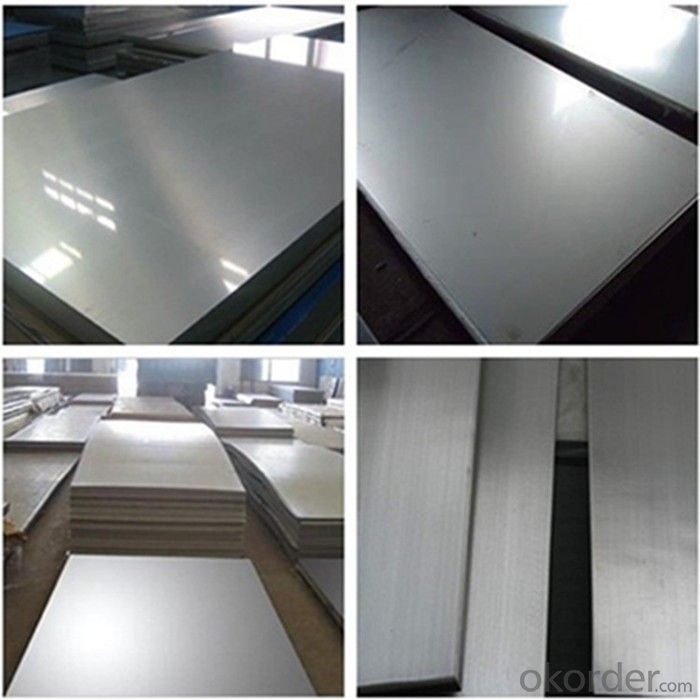

Surface | No.1 / No.4 / BA / 2B/HL/mirror/polished/brushed(bright annealed, surface not oxidati and brighter) |

Standard | JIS,AISI,ASTM,GB,DIN |

Delivery time | About10 days |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

Attention: the specifications can be customized .

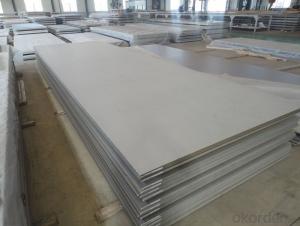

Product Show

Packaging & Shipping

Surface

Surface | Definition | Application |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

NO.3 | Those finished by polishing with No.100 to No.120 abravise specifiled in JIS R6001. | Kitchen utensils, Building construction |

NO.4 | Those finished by polishing with No.150 to No.180 abravise specifiled in JIS R6001. | Kitchen utensils, Building construction, Medical equipment |

HL | Those finished polishing so as to continuous polishing steaks by using abravise of suitable grain size. | Building construction |

BA(NO.6) | Those processed with bright treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction |

Mirror(NO.8) | Shinning like a mirror. | Building construction |

Our Services

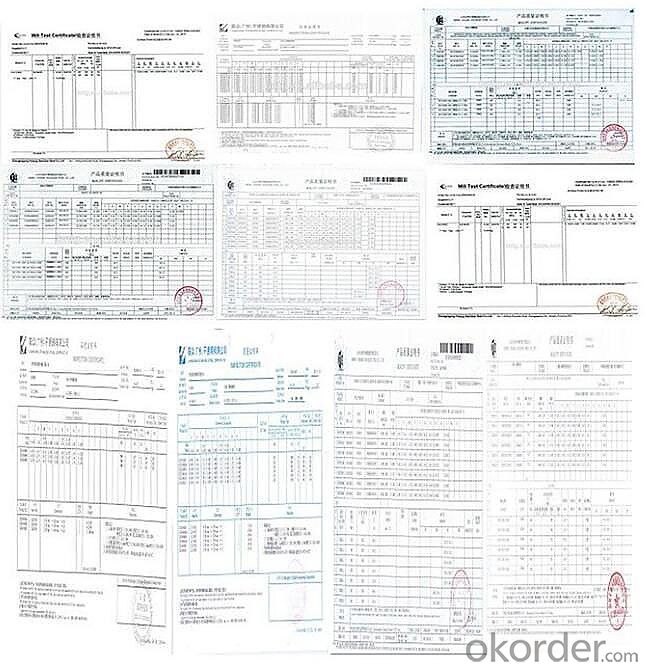

Mill test certificate--stainless steel sheet

Application

- Q: Can stainless steel sheets be used for backsplashes?

- Yes, stainless steel sheets can be used for backsplashes. Stainless steel is a popular choice for backsplashes due to its durability, resistance to heat and moisture, and easy maintenance. It can handle the heat and moisture that is often present in kitchen areas, making it a suitable material for protecting walls behind stovetops and sinks. Additionally, stainless steel backsplashes can add a modern and sleek look to the kitchen, complementing various design styles. They are also easy to clean, as they can be wiped down with a damp cloth or cleaned with mild soap and water. Overall, stainless steel sheets are a practical and aesthetic choice for backsplashes in both residential and commercial settings.

- Q: Are stainless steel sheets suitable for automotive exhaust systems?

- Certainly, stainless steel sheets are indeed appropriate for automotive exhaust systems. Due to their remarkable resistance to corrosion, heat, and vibration, stainless steel is highly sought after as a material for exhaust systems. It possesses the ability to endure the extreme temperatures and harsh conditions that exhaust systems encounter, rendering it a robust and enduring option. Moreover, stainless steel exhibits exceptional thermal conductivity, facilitating the efficient dissipation of heat. Additionally, it provides good formability, granting manufacturers the flexibility to design and mold the exhaust components according to their requirements. All in all, stainless steel sheets emerge as a dependable and widely favored selection for automotive exhaust systems.

- Q: How do you prevent scratching on stainless steel sheets during handling and installation?

- To prevent scratching on stainless steel sheets during handling and installation, it is important to follow a few precautions. Firstly, ensure that the work area is clean and free of debris that can potentially scratch the surface. Using non-abrasive gloves or handling tools can minimize direct contact and reduce the risk of scratching. Additionally, placing a protective film or adhesive tape on the sheet's surface can provide an extra layer of protection during transportation, handling, and installation.

- Q: 304 stainless steel plate surface quality inspection method which has several?

- Attachment of cold processing such as workpiece surface lubrication oil, must be fully skimmed in trichloroethylene degreasing agent, caustic soda solution and then with warm water washing, and then heat treatment. Stainless steel plate, if the surface of debris, especially organic matter or ash attached to the workpiece, heating, of course, will have an impact on the oxide skin. Stainless steel plate furnace atmosphere difference, furnace atmosphere in each part of the different, the formation of oxide skin will change, and this is also caused by uneven acid cleaning reasons. Therefore, when heating, the atmosphere in each part of the furnace must be the same. For this reason, the cycle of atmosphere must also be taken into account. Also, a heating workpiece with bench brick, asbestos, if contain water, when heated, water will evaporate, differences in direct contact with the water vapor and other parts of the atmosphere will produce, the formation of oxide of course is different. Therefore, objects that are in direct contact with the heating workpiece must be thoroughly dried before use. However, after drying, such as placed at room temperature, moisture in high conditions, the water will still condense on the surface of the workpiece. So, it's better to dry before use. If the local processing of stainless steel plate before heat treatment with oxide remaining, after heating with oxide remaining parts and parts without oxide, differences in composition and thickness of oxide skin will appear on the surface after pickling caused by uneven, so we should not only pay attention to the final heat treatment, but also to the full note that the middle heat treatment and pickling. There is a difference between the surface of stainless steel and the place where it is not touched.

- Q: Are stainless steel sheets good for pressure piping?

- Yes, stainless steel sheets are excellent for pressure piping due to their high strength, corrosion resistance, and ability to withstand extreme temperatures.

- Q: Are stainless steel sheets resistant to chemicals and acids?

- Yes, stainless steel sheets are generally resistant to chemicals and acids due to the protective layer of chromium oxide that forms on their surface, which prevents corrosion and damage.

- Q: What are the different types of stainless steel sheet textures available?

- There are several different types of stainless steel sheet textures available, each offering a unique aesthetic and functional appeal. Some of the commonly used textures include: 1. Brushed: This texture is achieved by brushing the stainless steel surface with abrasive materials in a unidirectional pattern. It creates a smooth, satin-like finish that is commonly seen in kitchen appliances and decorative applications. 2. Mirror: As the name suggests, this texture creates a highly reflective and mirror-like surface. It is achieved by polishing the stainless steel sheet using progressively finer abrasive materials until a reflective finish is obtained. Mirror-textured stainless steel sheets are often used in architectural and decorative applications. 3. Embossed: This texture involves imprinting patterns or designs onto the stainless steel sheet using embossing rollers. The raised patterns add depth and visual interest to the surface, making it a popular choice for interior design applications such as wall cladding or elevator panels. 4. Perforated: This texture involves creating a pattern of holes or perforations on the stainless steel sheet. It allows for the passage of light, air, or liquids while adding a decorative element to the surface. Perforated stainless steel sheets are commonly used in architectural, interior design, and filtration applications. 5. Etched: This texture is achieved by chemically etching the stainless steel surface using acid or other corrosive substances. The etching process creates a pattern or design on the surface, resulting in a visually appealing, textured finish. Etched stainless steel sheets are often used in decorative applications such as signage, elevator doors, or wall panels. 6. Hammered: This texture involves using hammers or other tools to create a hammered or dimpled pattern on the stainless steel sheet. It adds a rustic, textured look to the surface and is commonly used in architectural and decorative applications. These are just a few examples of the different types of stainless steel sheet textures available. Depending on the desired aesthetic and functional requirements, there are various other textures and finishes that can be applied to stainless steel sheets to achieve different looks and effects.

- Q: Can stainless steel plate spray paint?

- Topcoat. Because it is in the open, one hand paint with good weather resistance, on the other hand, it is very difficult to use paint, most of the prison film so that polyurethane paint is a two-component paint curing agent, without baking, the room temperature with the curing agent can be cured thoroughly. As the old brand is very good.

- Q: What's the difference between stainless steel hot rolling and cold rolling?

- 1. cold-rolled steel plate due to a certain degree of hardening, low toughness, the price is more expensive;2. surface anaerobic cold rolling scale, good quality;3. cold deformation products, high dimensional accuracy, good surface quality;4. cold rolling because of its production process in all walks of life in a wide range of applications, such as various types of cold stamping parts, cold rolled cold extrusion profiles, cold coil spring, cold drawn wire, cold heading bolts.Hot rolling (hot rolling): relative to cold rolling, cold rolling is performed under recrystallization temperature, while hot rolling is rolling above recrystallization temperature.

- Q: Can stainless steel sheets be used for elevator cabins?

- Yes, stainless steel sheets can be used for elevator cabins. Stainless steel is a popular material choice for elevator cabins due to its durability, aesthetic appeal, and ease of maintenance. It is resistant to corrosion, which is important in environments with high humidity or exposure to chemicals. Stainless steel sheets can be used to create sleek and modern elevator cabins that are both functional and visually appealing. Additionally, stainless steel is easy to clean and maintain, making it an ideal choice for high-traffic areas such as elevators.

Send your message to us

Stainless Steel Sheet Price 309 3mm thickness ba finished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords