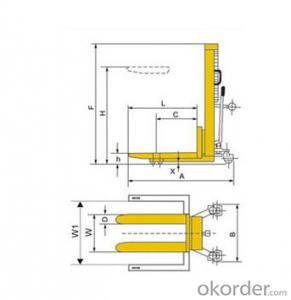

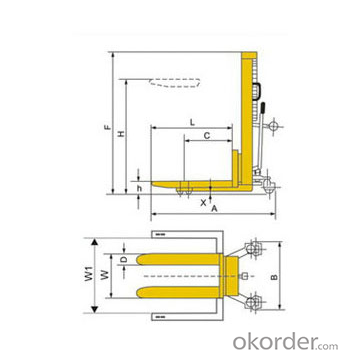

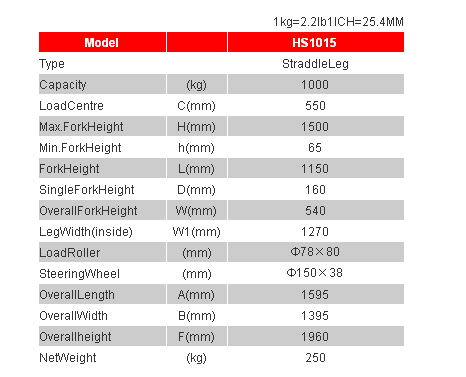

STACKER PRODUCT SERIE - Hand stacker-HS1015 HearvyDutyDesign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Materialsandspecificationaresubjecttochangewithoutnotice.

HearvyDutyDesign

Uniquetechnologyofquickliftsystem

Compactdesignandstrong,accuratesteelconstruction

TopqualityhydraulicpumpandcylinderwithGermanseals.

Heavyduty1piece"C"sectionforksforgreateststrength.

Topofstrokebypassvalvebuiltin.

ConformstoEN1757-1:2001

All products are granted CE or GS certificates by Rheinland Group. The products are widely used in the field of modern logistic. There are seven product categories and over 2000 sorts. Besides standard products, we also customizes according to your requirements.

We focus on improving our core competitiveness and grasp the trend of upsizing, intelligentizing and environmental friendly. Based on self-developement and innovation, we cooperate with scientific research institution and schools and study new products, technique and craft which are suitable for market.

Stackers and reclaimers were originally manually controlled, with no means of remote control. Modern machines are typically semi-automatic or fully automated, with parameters remotely set. The control system used is typically a programmable logic controller, with a human-machine interface for display, connected to a central control system.

Other than stacking, a stacker has three basic movements:

Luffing: This is vertical movement. Stackers use either a winch mechanism with metal wire, or hydraulic cylinders, generally two. Winch mechanisms are highly reliable compared to hydraulic actuators and remain widely used, particularly in large stackers.

Travelling: The stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move around the stockyard as required. For this purpose, traction motors powered by direct current (DC) are connected by bevel gears to between 12 and 22 wheels. For manual control, all the controls are in a controller's cabin above the boom conveyor or boom. Modern stackers can be controlled remotely.

Slewing: This is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear. The axles may be multiple and are driven by DC-powered axle motors which transmit the torque via bevel or helical gears.

The conveyor belts used in stackers may be made of fabric or metal wire, depending upon the material to be handled. They are driven by pulleys, which in turn are driven by DC motors. The motors and gear are coupled by fluid coupling.

Most stackers are electrically powered by way of a trailing cable. There are basically two types of cable trailing: power cord rotating drum (PCRD) and control cable rotating drum (CCRD). Pendulum adjustments are made to ensure the proper alignment of these cables while the stacker is travelling.

- Q: How much is the 8 square meter tatami mat

- Look at the material you choose. Eight is not too small. It is estimated to be around 5,000-1w, without a lift

- Q: Who knows the price of a sloping platform?

- You're asking too much! Do you know how big is your mesa, aspect, slope, a direction tilt, lifts the lowest, highest, up to how much time and so on, is behind the question welcome phone

- Q: What kinds of tables are there? Which is better for the office?

- Lift table many brand, currently on the market the main lifting table is divided into: electric hoist, mechanical lifting table (barometric, mechanical lifting), electric lift table when the disadvantage is that there was no electricity can't use our company with polly lifting table, manual lifting regulation, any place to stay, very effort; And it can move back and forth

- Q: Does the shear fork lift stand belong to special equipment?

- In the light of the special equipment safety supervision regulations, hoisting machinery definition: refers to used for vertical lifting or vertical and horizontal moving heavy mechanical and electrical equipment, its range is rated lifting weight greater than or equal to 0.5 t lift.

- Q: The design of graduation is designed for mobile shearing and hydraulic lift

- Has offices in the major cities, buy convenient, jinan Long Hao hydraulic machinery is the main production: elevator, lift platform, lift platform, elevator, cllimbing trolley, hydraulic lift, hydraulic lift platform, hydraulic lifting platform, hydraulic lifts, hydraulic dock leveler, imobile elevator, stationary lift platform, fixed lifts, fixed lifts, stationary dock leveler, mobile lift, lift platform, lift platform, portable lifts, mobile cllimbing trolley, goods elevator, cargo-lifts, hydraulic cargo-lifts, stationary cargo-lifts

- Q: To make a four trapezoid screw lifting up seven tons of lifting platform should be matched with the straight screw and motor

- A lift platform system, we are doing, you should tell your system speed, accuracy, and so on parameters, can calculate the motor power, speed, lead, lead screw diameter, guide rail, can communicate in detail

- Q: There are several categories of mobile elevators

- Knowledge of mobile elevators is almost there. Mobile hoist considering the mobile convenience more considering the high stability, wide operating platform and high bearing capacity, can make the work high above the range larger, more wide, many people work at the same time. Improving the efficiency of the work is a safe place for people.

- Q: Operation and attention of electric elevating platform car?

- ?Gives you an explanation of the items of electric elevator: In order to ensure the use of safety and keep the machine in good working condition, the appearance performance check should be performed first. The inspection is as follows: Using the operating: A, the power cord is in good condition; B, the buttons are valid; C, oil pipelines, etc. D, the intersections of the intersections of the arm frame are fastened.

- Q: Put a large beaker of water on a horizontal platform and put a light glass upside down in the water

- Rise slowly lifts A certain height, because the process is slow cooling can in time, and the environment temperature balance, and can be regarded as constant temperature, the glass is immersed in the water depth increases, the gas pressure increase, to A.

- Q: Safety operation of hydraulic platform

- Purpose: this procedure is used to guide operators to operate correctly and use hydraulic platform equipment. Two procedures: 1, the parts should be inspected carefully before they are work lifting platform, key check whether the screw connection is reliable, hydraulic pipe leaks, loose wires contact with and without, breakage, and so on and so forth. 2, lifting platform lift, put the leg in the four corners, four leg should be firmly supported on solid ground, dispatch work mesa to state level (visual). Turn on the power, the indicator should be on. Then start the motor, pump work, drop one or two in the air, check the parts and then start working again. When the temperature is below 10 ℃, should make the pump running 3-5 minutes, confirmation of oil pump work can be carried out. 3, homework personnel enter the platform after the guardrail doors should be closed, with bolt, tied on safety rope, the center of the load (people stand location) should be in the center position of workbench face.

Send your message to us

STACKER PRODUCT SERIE - Hand stacker-HS1015 HearvyDutyDesign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords