Gypsum Ceiling Frame Square Hole Perforated Wooden PVC Facing Gypsum Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

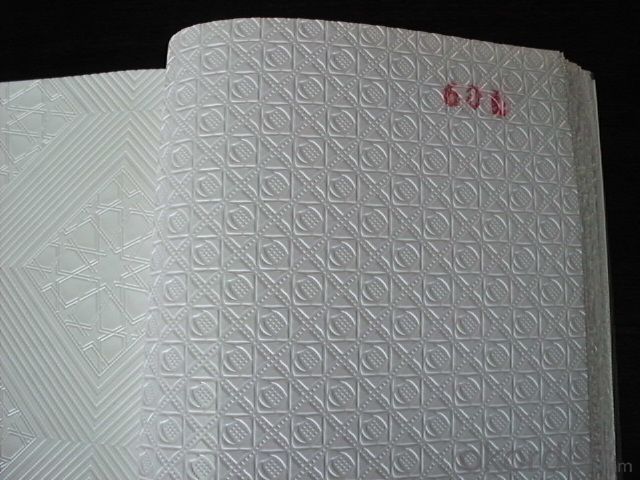

Perforated gypsum ceiling

square hole

Circle Hole

Irregular Circle Hole

paper-faced or PVC facing+aluminum foil backing

a.Standard size:2400*1200*12.5mm,3000*1200*12.5mm,600*600*9.5/12.5mm

b.Round hole dia.: Φ6mm, Φ8mm, Φ12mm, Φ15mm

c.Back non-woven fabric colour:white,black,blue

d.Weight:9.4kg/m2

e.Perforation rate:8.7-19.6%

f. Acoustic performance

aw:0.65

NRC:0.70

RH70

g.Application:drywall, ceiling

Each 16 rolls Paper Joint Tape(5cm*100mm) for every container.

a.Standard size:2400*1200*12.5mm, 600*600*9.5/12.5mm

b.Hole type: Φ6/10, Φ12/20, Φ35/20/12, Φ20/12/8

c.Back non-woven fabric colour:white,black,blue

d.Weight:10.7kg/m2

e.Perforation rate:8.7%-18.1%

f.Acoustic performance

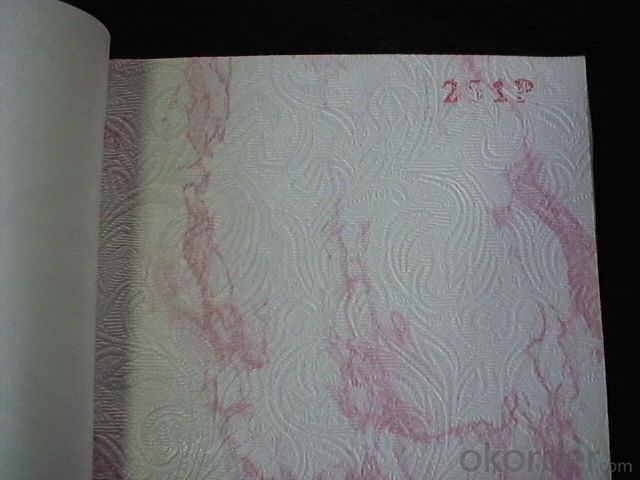

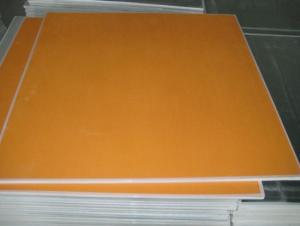

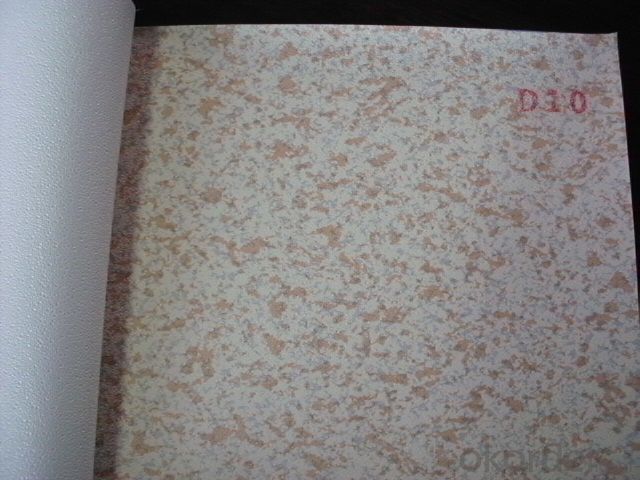

3.Image

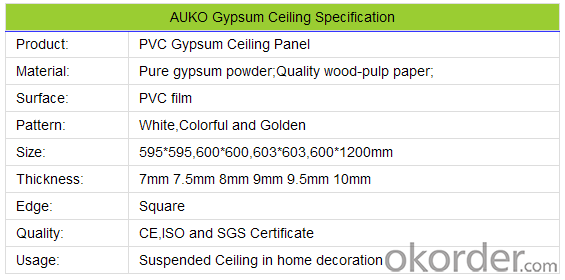

4.Detailed Specification

5.FAQ

Applications

It can be designed with different sizes and styles, widely used for interior ceiling decoration.

Trust us from heart cooperation

Reasonable price

Unique quality

Schedule delivery on time

Updated technology and equipment

Service warmly

1) Commercial & good for decorative

2) Flexible suspension system makes each ceiling tile easily installed and disconnected

3) Easy to match lamps or other ceiling parts

4) Many different pattern

5)PVC film & Aluminum foil back , moisture proof

- Q: Wood keel gypsum board ceiling price is the number of a flat artificial?

- Wood keel gypsum board ceiling to see the difficulty of the size of the project, while the larger the relative amount of the relative price will be slightly reduced. The general level of flat and multi-level ceiling and special-shaped ceiling, flat roof labor costs in 18 ~ ~ 20 yuan per square meter, multi-level ceiling in the flat on the basis of each additional level of 5 ~ ~ 8 yuan, that is, In the 23 ~ ~ 28 yuan, and so on; the opposite sex, including arc and other non-plane natural form, the price will be doubled, as difficult to view, generally to loft and repeated check, relatively difficult, labor costs at least 40 yuan Per square meter, high can reach 80 yuan per square meter is also very common!

- Q: Want to be in the living room and dining room around the kitchen together about 36 square feet. The middle is not hanging. Need to find someone to do it. What materials are needed. Around the ceiling + spotlights + lights with a total estimated how much cost. The Master come Thank you How much money will be budgeted together? The I do not know this is not the middle of the lamp is not included. Just do a four-week ceiling, and spotlights. (You can not buy such a expensive shot, etc.). how much is the total

- Looking for carpentry, with decorative panels and gypsum board

- Q: My house is decorated with a good ceiling, and now when the crystal lamp installed when the workers said afraid of hanging. How to do ah, it was said that with the expansion of the lamp hanging on the top of the lamp, my mother afraid to unload the heavy unloading, is not it very troublesome ah?

- The gypsum board cut off about 200x200mm hole, called the workers with the impact of the drill drill chandelier boom fixed to the ceiling, and so fixed, and then paste the gypsum paste this hole on a 200x200 gypsum board can be, The painter can not see it.

- Q: Ready to do at home to do the ceiling, the top of the wire how to go, what kind of need to use the wire, how fixed line, how to build the line, please introduce some of the details

- Sheathed cable. The Ordinary two heart. The Individual lights will be three heart. The No need to - pay attention to the switch when the fire can be connected to the line

- Q: Corridor gypsum ceiling calculation area method

- According to the expansion area, the length of the plane plus the length of the long ride, long by the width is the flat area, high from the original ceiling down to the lowest end of the gypsum board height, for example, the ceiling size is 6 meters long 2 meters wide, from the original ceiling hanging down 0.3 meters. The calculation method is: (6x2) + (6x0.3) hope to help you

- Q: Living room gypsum board ceiling, there are half a year, and want to demolish it, is it a lot of trouble? Inside the wire and light line, how to do?

- There are a lot of dust in the demolition. [Inside the wire and light line, how to do? If there is no hanging in the future, then you can only line the line, along the ceiling laying protective tube of the open line, the lamp will hang under the ceiling (chandelier), or with a ceiling lamp mounted on the ceiling. The line to do good words, but also very good to see, but at present, according to the standard line of people who are not many lines, who will drop the dark line.

- Q: is gypsum board or plaster ceiling contents gypsum safe ? i mean for long term effects to health?

- Short term exposure is no problem with most minerals in the building trade, long term exposure can cause scar tissue/fibrosis build up in the lungs and a remote chance of cancer. Get some dust masks they don't stop it all but they are better than nothing.

- Q: Gypsum board secondary ceiling generally out how much

- 15 centimeters or so, the inside can be installed reflective light tank.

- Q: It is often said that the ceiling is not integrated ceiling

- People often said that the ceiling is not integrated ceiling is not the former is the gypsum board ceiling, also known as large board ceiling, office ceiling 600 * 600 small plate ceiling, home decoration, living room, bathroom, balcony kitchen is called integrated ceiling, integrated ceiling is In order to solve the lamp and the top of the plane one, durable PVC (including plastic, the state has a ban on plastic, do not know including pvc).

- Q: My house decoration, ceiling in the end with gypsum board or aluminum plate is good? Home in the countryside, pay attention to is beautiful, practical, atmospheric, simple, beautiful and practical is the key, in the end how to choose? Two halls two bedrooms a store, the next three on the two, no kitchen.

- Gypsum board ceiling is generally used in the bedroom, living room and other dry and smoke-free environment, fear of water, and the surface brush latex paint, if dirty, not so easy to clean aluminum plate. Can be free to do all kinds of shapes, brush a variety of colors. Aluminum buckle plate is integrated ceiling, is the alloy material. Beautiful, but can not do a special shape, but the pattern has a variety of easy to clean up, are generally used in the kitchen. Suggest that you both use, can be used in a more appropriate place

Send your message to us

Gypsum Ceiling Frame Square Hole Perforated Wooden PVC Facing Gypsum Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords