Zircon Brick for Slag Resistance Zircon Mullite Hot Blast Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Zircon Mullite Brick

CMAX Zircon Mullite Bricks are made of sillimanite minerals and by high-temperature firing method and slurry casting method to produce.

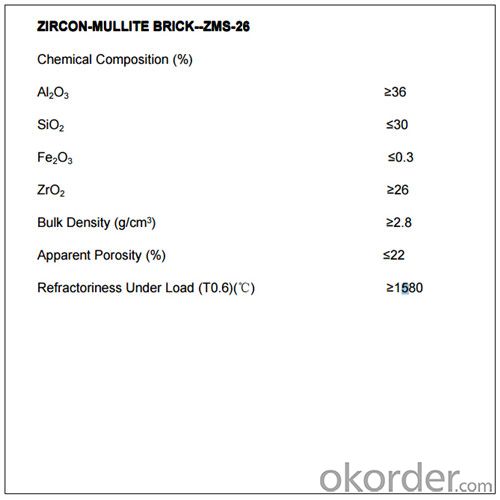

Technical Data of Zircon Mullite Brick

Feature of Zircon Mullite Brick

Good refractory properties

Good stability against thermal shocking

Application of Zircon Mullite Brick

Blast furnace

Glass melting kiln

Image of Zircon Mullite Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What are the ingredients in the binder of the yttrium zirconium brick?

- Of course, this is only a general component of the situation, usually in different use environment, the ratio of various additives is different, so the specific quantity is subject to specific analysis.

- Q: What metal materials withstand 1000 degrees high temperature long burning contact with open flame?

- Zirconia brick can withstand 2600 degrees high temperature and good heat insulation performance and long service life

- Q: What's the difference between zirconium and zirconia? What are the fields in which applications?

- Zirconia according to the production process is different, divided into two kinds of zirconium and zirconium carbide ~ ~ ~!

- Q: Continuous basalt fiberThere are several questions that we write on paper!Please let me know if you have any information about itHow to choose the heating system for the crucible furnace?The commissioning process of the furnace?

- Glass fiber drawing machine is a kind of mechanical equipment which is made by winding glass fiber at high speed.Wire drawing apparatus for making glass fibresThe drawing parts are mainly crucible, pool furnace, wire drawing machine and temperature control system.

- Q: What is a zirconium drill? Is it valuable?

- In choosing zircon, you should first consider the choice of zircon, the most popular blue, blue is often considered as a panacea universal color. For women, the most important point is to coordinate with their eyes and hair, although many ladies love match, aquamarine aquamarine, but not so bright is not like zircon, zircon shine. Colorless zircon is recommended, especially want to buy a piece of jewelry, and are unwilling to invest in expensive diamond, then choose colorless zircon can be said to be saving money, shoot two hawks with one arrow, and achieves the purpose of beautifying life. Generally, a zircon ring is only a few dozen yuan.

Send your message to us

Zircon Brick for Slag Resistance Zircon Mullite Hot Blast Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords