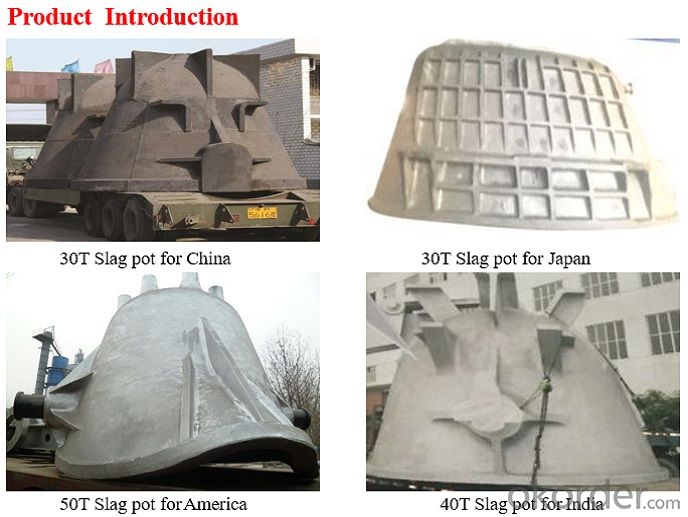

Slag Pot with Large Capacity Factory Price for Metallurgical Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Slag Pot

The slag pot is a metal ladle for collecting molten slag flowing from the taphole of a steel-smelting furnace during smelting. It is positioned under the furnace on a car that moves along a special trestle.

Company Profile

CNBM International Corporation (CNBM International) is one of the primary subsidiaries of CNBM Group, and has established strategic partnerships with hundreds of domestic manufacturers and sounded business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches more than 5 countries with a view of achieving localization, which also represents an essential progress in our globalization target.

We specialize in Metallurgical product, such as Slag pot, Valve, pump, BOF Lance Tip, Slag pot transfer car, Mill rolls, Bearing etc. We supplied our Slog pot to Korea, Europe, Japan , America, Mexico, India, Vietnam, Australia etc.

Our products comply with relevant European and International standards and are all manufactured under the quality management system ISO 9001. Very proud to say that each one of our products possesses high quality and competitive price, let alone having been exported worldwide and built up great reputation in quality and service among global customers.

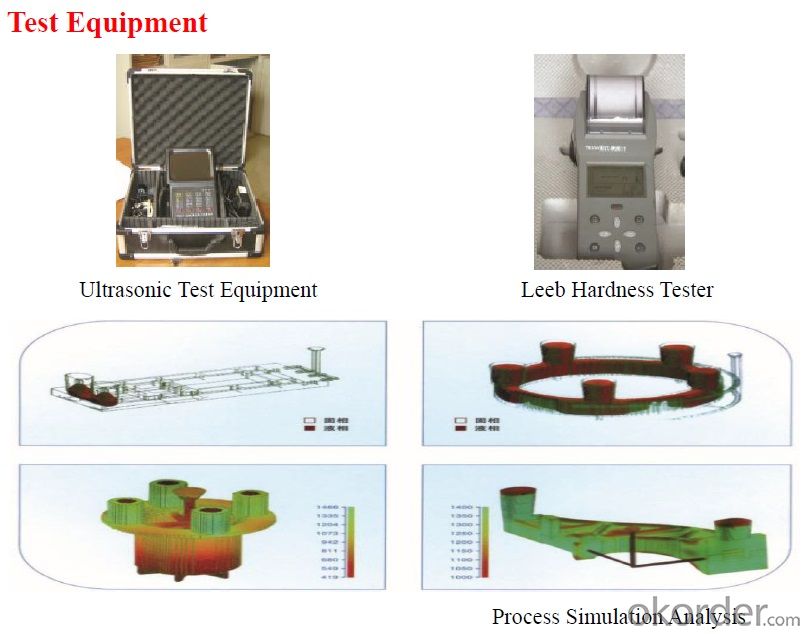

Lab&Test Equipment

Inspection requirements and standards

Nondestructive Testing (NDT) requirements

1) The magnetic particle inspection (MT) and ultrasonic inspection (UT) of trunnion are conducted according to the general technical conditions of heavy machinery JB / T 5000.15-2007, and the forged steel parts are not damaged. The test was carried out at level II.

2) Magnetic particle inspection (MT) and ultrasonic inspection (UT) of slag tank body shall be in accordance with GB / t9444-88 grade III and GB / t7233-87 grade III respectively. Magnetic particle inspection area

Domain: trunnion area of slag tank, all r-corners outside and inside of slag tank.

3) Ultrasonic flaw detection area: inner bottom diameter of slag tank is 1m: wall thickness of 9 places randomly measured by ultrasonic testing. (the Seller shall provide corresponding rulerInch report and NDT report)

4) Ensure that the slag tank is cast and formed at one time without cold separation; after finishing, no welding point is allowed.

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- I am doing this for sale, if the price is mainly based on the product structure, the difficulty of pricing. At present, if it is more formal and material guarantee manufacturers generally in 48-53 yuan /Kg (of course, products have a certain weight, such as greater than 100g), our company's current price of about 53 yuan /Kg or so. .

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- The clay wet sand castings casting weight from a few kilograms until tens of kilograms, but the clay dry type of casting production can be weighed dozens of tons.For medium and large castings, cast iron, cast steel can be self hardening sand with resin can be water glass sand production, can obtain the precise size, smooth surface castings, but casting precision, surface roughness, density and microstructure, mechanical properties and material cost of sand casting production is often poor, so when the higher performance requirements of castings, should adopt other casting methods, such as casting (lost wax casting), die casting, low pressure casting.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What is the casting material?

- Commonly used gray cast iron, malleable cast iron, ductile iron, cast steel, etc., non-ferrous metal casting copper alloy, casting aluminum alloy, casting zinc alloy, etc..

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

- Q: What's the cause of the choking of the casting?,

- Causes of choking fire:1., casting material in the pouring of gas;

- Q: How can the casting be free of trachoma?

- 2, pouring temperature should be enough, otherwise the sand can not float up;

Send your message to us

Slag Pot with Large Capacity Factory Price for Metallurgical Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches