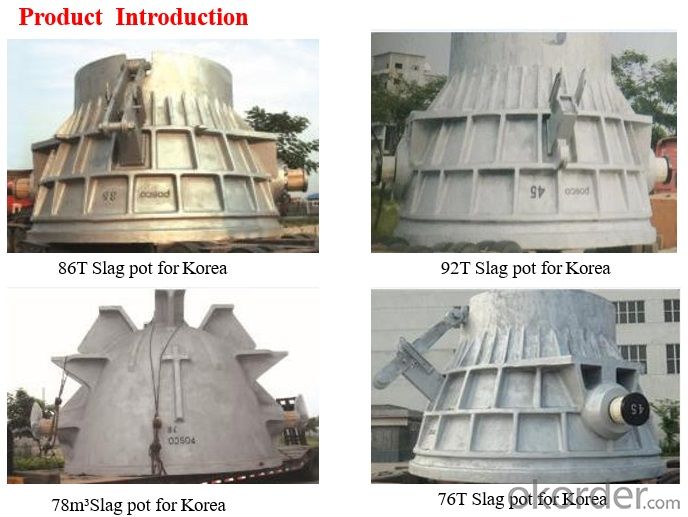

Slag Pot with Factory Price Long Life for Metallurgical Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Slag Pot

The slag pot is a metal ladle for collecting molten slag flowing from the taphole of a steel-smelting furnace during smelting. It is positioned under the furnace on a car that moves along a special trestle.

Company Profile

CNBM International Corporation (CNBM International) is one of the primary subsidiaries of CNBM Group, and has established strategic partnerships with hundreds of domestic manufacturers and sounded business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches more than 5 countries with a view of achieving localization, which also represents an essential progress in our globalization target.

We specialize in Metallurgical product, such as Slag pot, Valve, pump, BOF Lance Tip, Slag pot transfer car, Mill rolls, Bearing etc. We supplied our Slog pot to Korea, Europe, Japan , America, Mexico, India, Vietnam, Australia etc.

Our products comply with relevant European and International standards and are all manufactured under the quality management system ISO 9001. Very proud to say that each one of our products possesses high quality and competitive price, let alone having been exported worldwide and built up great reputation in quality and service among global customers.

Factory

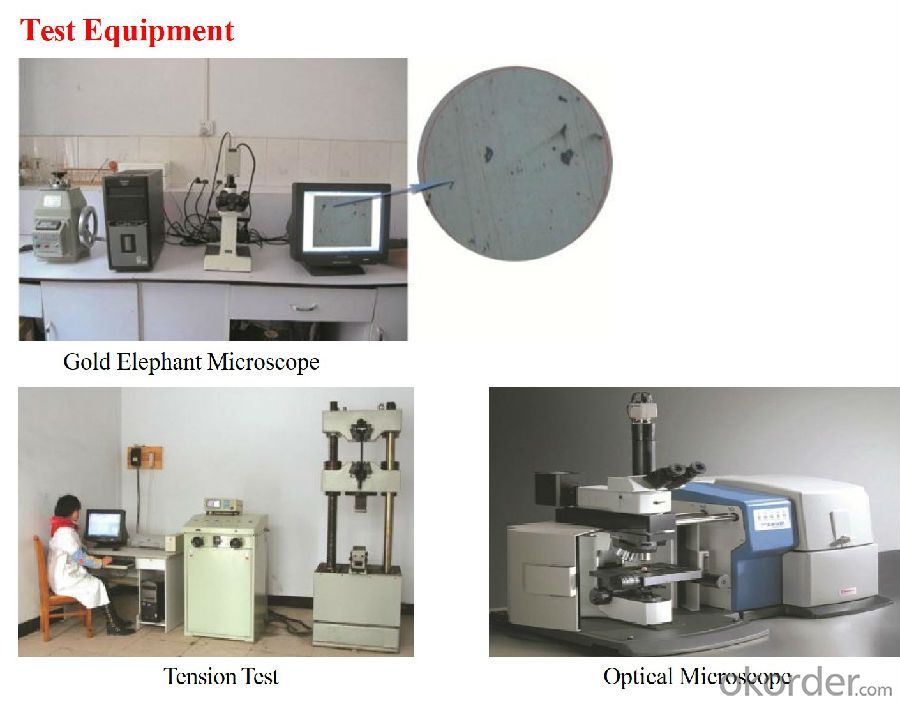

Lab&Test Equipment

Inspection requirements and standards

Nondestructive Testing (NDT) requirements

1) The magnetic particle inspection (MT) and ultrasonic inspection (UT) of trunnion are conducted according to the general technical conditions of heavy machinery JB / T 5000.15-2007, and the forged steel parts are not damaged. The test was carried out at level II.

2) Magnetic particle inspection (MT) and ultrasonic inspection (UT) of slag tank body shall be in accordance with GB / t9444-88 grade III and GB / t7233-87 grade III respectively. Magnetic particle inspection area

Domain: trunnion area of slag tank, all r-corners outside and inside of slag tank.

3) Ultrasonic flaw detection area: inner bottom diameter of slag tank is 1m: wall thickness of 9 places randomly measured by ultrasonic testing. (the Seller shall provide corresponding rulerInch report and NDT report)

4) Ensure that the slag tank is cast and formed at one time without cold separation; after finishing, no welding point is allowed.

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q:Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- The performance is too extensive, I think the following several people all fall into the erroneous zone directly, the performance includes a series of aspects:Mechanical properties: tensile strength, yield strength, elongation and contraction ratio of section and impact toughness after etc.

- Q:Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q:Is the cast steel a casting part?

- Cast steel is divided according to material, as well as cast iron parts, cast aluminum parts and so onCasting parts are divided according to the method, as well as forging partsCast steel parts must be casting parts

- Q:As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q:What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q:What is the difference between forging parts and casting parts?

- The casting parts are low in cost and short in production period. Because the molten iron has good flow properties, complex shapes can be formed. But because there may be sand holes, pores, shrinkage holes and other defects, the quality is unstable, easy to produce many defects, mechanical properties are not forged well, thus affecting the service life.

- Q:What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q:What is the casting material?

- Commonly used gray cast iron, malleable cast iron, ductile iron, cast steel, etc., non-ferrous metal casting copper alloy, casting aluminum alloy, casting zinc alloy, etc..

- Q:Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron.

- Q:In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Slag Pot with Factory Price Long Life for Metallurgical Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches