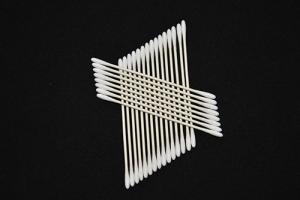

Sindle Needle and Double Needle Mesh Scourer Machine with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.scouring making machine

2.high quality,wholesale price

3.packing in wooden box

4.CE certification

5.easy operation

Main Features:

Voltage Supply: AC 380V/AC 220V

Power (KW): 2.2KW

Output: 12-15kgs/hour

Materials:

Diameter 0.22mm Stainless Steel Wire, Galvanized Iron Wire, Iron Wire, copper wire, brass wire etc.

Full-automatic operation,available for mesh pot scourers scrubbers!

safe operation:

Full-automatic scourer ball-dividing system.

Final scourer separating melted down by low voltage controlled. It made shearing more accurate, sharper and safer.

Easy operation:

Easy operation, one worker controls multiple machines. Wire loading, flatting, scourer forming and scrubber cutting, all finished in one time. Producing general scourer just by exchanging the multi-lines system.

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- First, the source and composition of the oil pollution should be made clear. In particular, it is clear that it is possible to take medicine against the disease. The oil on general equipment is divided into two categories: lipids and oils. The best way to deal with lipids is by physically removing and chemical decomposition. In the case of oils, the main thing is chemical decomposition. Because you do not know the type and structure of your device, you can only suggest the following: 1, before manual cleaning, the specific chemical decomposition should be arranged so that the cleaning can be twice as effective. According to the source of the oil pollution, do the precautionary setting. For example, it is easier to paste the protective coating on the spot where the oil pollution is frequently occurring. Use special tools and equipment to clean up the oil. Personal sense, the process of decomposition is important. For your reference.

- Q: What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q: What are the benefits of sanitation

- The protection equipment and make it is not too bad

- Q: Characteristics of cleaning equipment of cleaning equipment

- High pressure water jet cleaning mainly has the following characteristics: (1) selecting the appropriate pressure level, the water jet cleaning will not damage the base of the cleaning equipment. (2) is using ordinary tap water with a high speed washed clean, so it does not pollute the environment, anti-corrosion equipment, won't cause any mechanical damage, can also be removed with chemical cleaning of refractory or cannot dissolve the special scale; (3) after washing, the equipment and parts shall not be cleaned; (4) cleaning parts that are complex in shape and structure, which can be cleaned in a space narrow, complex, hostile and harmful environment; (5) it is easy to achieve mechanization, automation and digital control. (6) save energy, clean efficiency and low cost. Chengdu feng cleaning machine, with its strong technical force and reliable after-sales service protection, the pressure washer in the domestic many areas have a large promotion, cleaning machines are exported to overseas markets, done a good job in the technology field.

- Q: What are the sanitation facilities?

- Sanitation equipment including road cleaning equipment, trash pickup device, the landfill treatment equipment, now the fog haze weather serious mainstream sanitation develop haze reduction equipment manufacturer. And so on.

- Q: How often do the reverse osmosis of pure water equipment wash the search?

- Generally 3 ~ 12 months clean, if every month had to be cleaned once, this explanation should improve the pretreatment system, adjust the running parameter. If you need to clean it once or three months, you will need to improve the operating level of the equipment, and it is difficult to determine if you need to improve the pretreatment system.

- Q: What are the methods of general cleaning of mechanical equipment?

- It is commonly used for dry cleaning and washing 1, dry cleaning: it is with a bit like a sponge absorbing water materials, such as spray (drop) some detergent or anything on the brush, complete with relatively wet objects in to wipe again, finally just now with the dry items all dry clean place (general comparison precision of the equipment) 2, rinse directly with water, direct and clear, and then dry (directly dry, the equipment is large). This kind of equipment is not afraid of water Most of it comes in the first way

- Q: How do you clean the household central air conditioner

- It is mainly the filtration grid that is cleaning outlet, if can ask professional person to clean the wind channel is better

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- Remember a TV show that USES a bowl of lemon water cloth cover, ten minutes of evaporation and then a soft cloth to wipe it off without a chemical smell.

- Q: Is there any molding equipment in the car engine?

- We now have the patent equipment hydrogen carbon removal machine, especially the combustion chamber carbon cleaning cars, clean up three yuan may oxygen sensor at the same time, only for 15 minutes, without having to remove the parts, don't need an oil change

Send your message to us

Sindle Needle and Double Needle Mesh Scourer Machine with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches