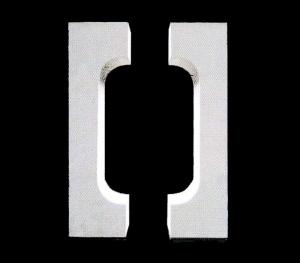

Sillimanite Brick SAS60C

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t

- Supply Capability:

- 500 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silimanite Brick---SAS60C

General Information of Silimanite Brick SAS60C

CMAX silimanite bricks are based on silimanite raw materials. The SAS60C silimanite bricks have 58% alumina content with low iron content. The SAS60A silimanite bricks are produced by casting method. And CNBM can do all kinds of shapes under customer’s request.

Characteristics of Silimanite Brick SAS60C

Compared with the high alumina bricks, silimanite bricks have the following characteristics:

High tensile strength

Strong resistance to crossion

Thermal shock resistant

Typical Application of Silimanite Brick SAS60C

The silimanite bricks could be used in the steel and non-ferrous metals industry, which are in direct contact with liquid metal are possible. The sillimanite bricks are good for refractory solutions in the glass industry, cement industry and incineration, for industrial processes with rapid thermal shocks, in furnaces for firing biomass and in production kilns of the ceramic and refractory industry.

Technical Data of Silimanite Brick SAS60B:

|

Sintered Silimanite Brick---SAS60C | ||

|

Physical Properties: |

|

|

|

Refractoriness |

℃ |

1790 |

|

Apparent Porosity |

% |

26 |

|

Bulk Density |

Kg/m3 |

220 |

|

Cold Crushing Strength |

Mpa |

50 |

|

Refractories Under Load(0.2Mpa) |

℃ |

1450 |

|

Reheating Linear Change (1500 ℃x2h) |

% |

+0.1~-0.3 |

|

Chemical Analysis: |

|

|

|

Al2O3 |

% |

58.0 |

|

SiO2 |

% |

37.0 |

|

Fe2O3 |

% |

1.0 |

|

Note: Technical Data are typical average results from test pieces.The technical data is offered solely for your consideration.And CNBM reserve the right to modify the technical data without any prior notice.Users of CNBM products should make their own tests to determine the suitability of each products for their particular purposes. | ||

CNBM has success in silimanite bricks due to their excellent thermal shock resistant and resistant properties. CNBM also has experience in silimanite bricks application and would like to assist you in product selection, system design, and installation techniques.

- Q: I am a student of refractory materials. I would like to know the general rank of national refractory materials company

- Zhejiang Sunon Refractories Co., Ltd. is a group member of the factory of industrial economy research China (country), building materials building materials industry center Changxin Branch Center of refractories. The main products are: wear-resistant refractory brick, aluminum silicate fiber board, ordinary magnesia, heavy casting materials, spalling brick kilns, special casting materials, high strength and abrasion resistant castable refractory castable, special pulverized coal burner, MF-170 coating (with fabric), clay brick, corundum wear-resistant plastic, calcium silicate board, lightweight castable and the direct combination of magnesia chrome brick, unburned magnesia chrome brick, anti flaking high alumina brick, mullite brick, antiskinning castable,

- Q: What kind of refractory material will be used in the glass kiln?

- 2. dense zirconia brickHigh temperature & glass corrosion performance of the brick is slightly lower than that of chromium oxide, also by isostatic pressing forming method, its technical indicators ZrO2>65%, <2.0% porosity, volume density of about 4.25g/cm3, the temperature in E glass is higher than 1370 DEG C have erosion. Used in the E glass melting pool unit kiln glass temperature slightly lower at the end of the transition path, forming the bottom of the pool and forming path path flow tank and bushing support brick etc.. In addition, the dense zirconia brick is used as the backing brick of the dense chrome brick.

- Q: Is it good for your cupola to use that kind of refractory, high aluminum brick, clay brick or red silica?

- The high aluminum clay brick is slightly more stable and can be used!

- Q: Sillimanite brick

- 1 、 high temperature resistant abrasion resistant coating;2, sillimanite refractory fireball;3, styrene kaolin - sillimanite insulation refractory products;4. High strength unshaped refractory material is used for building high temperature kiln;5 、 rare earth composite silicon carbide material;6, a composite insulation high-temperature refractory coating;7 、 refractory castable with high temperature self strengthening effect.

- Q: What refractory materials are adopted in each part of the blast furnace?

- The blast furnace throat from top to bottom, stack, belly and Bosh, hearth and bottom etc.

Send your message to us

Sillimanite Brick SAS60C

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t

- Supply Capability:

- 500 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords