Silica Lime Bricks for Coke Oven CMAX-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

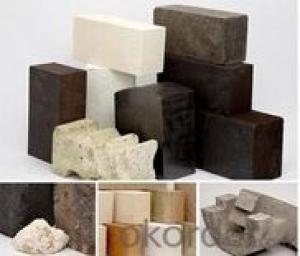

1. Silica brick is the main refractory bricks used in glass melting furnace;its main crystal phase is Tridymite.

2. Silica brick for glass melting furnace is used in building checker chamber, chute, combustion chamber,coking chamber,and furnace arch etc.

3. Silica brick for glass furnace have following characters:

(1)High refractoriness under load.

(2)High heat conductivity.

(3)Good thermal shock resistance.

(4)Solidity stable of capacity in high temperature.

Tech Data

Silica brick for glass furnace | |||||

Item: | GF-96A | GF-96B | GF-95A | GF-95B | |

SiO 2 | ≥96 | ≥96 | ≥95 | ≥95 | |

Fe 2 O 3 | ≤0.8 | ≤1.0 | ≤1.2 | ≤1.2 | |

Apparent porosity % | ≤22(24) | ||||

Cold Crushing Strength MPa | Brick below20KG | ≥35(30) | |||

Brick ≥20KG | ≥30(25) | ||||

Refractoriness under load ºC | ≥1680 | ≥1670 | ≥1660 | ≥1650 | |

True density g/cm ³ | ≤2.34 | ≤2.34 | ≤2.35 | ≤2.35 | |

Silica brick for coke oven | ||

Item: | CO-94A | CO-94B |

SiO2: % | ≥94 | ≥94 |

Al 2 O 3 : % | ≤ 1.5 | ≤ 1.5 |

Fe2O3: % | ≤ 1.5 | ≤ 1.5 |

Refractoriness under load 0.2Mpa | ≥ 1650ºC | ≥ 1650ºC |

Apparent porosity: % | ≤ 22 | ≤ 24 |

Bulk density: g/cm ³ | ≤ 2.34 | ≤ 2.35 |

Cold crushing strength: MPa | ≥30 | ≥25 |

Permanent linear change % (1450ºC ×2h) | 0~0.2 | 0~0.2 |

Thermal expansion(1000ºC) | ≤1.28 | ≤1.30 |

Silica brick for hot blast furnace | |

Item | HBF-95 |

SiO2 | ≥ 95 |

Al2O3 | ≤ 1.0 |

Fe2O3 | ≤1.3 |

Apparent porosity % | ≤22(24) |

Cold crushing strength MPa | ≥45(35) |

Remaining quarts % | ≤1.0 |

Refractoriness under load ºC | ≥1650 |

Creep(0.2Mpa ×1550ºC×50h) % | ≤0.8 |

Thermal expansion coefficient (1000ºC) % | ≤1.25 |

Apparent density g/cm ³ | ≤2.32 |

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: The introduction of silica brick

- The characteristics of silica brick:Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.The use of silica brick:Mainly used for masonry brick oven carbonization chamber, a combustion chamber and a partition wall, glass furnace and kiln roof, pool wall, high temperature hot blast furnace, glass furnace, load-bearing pool wall, hot blast stove, baking furnace of carbon bearing part of high temperature furnaces etc.. Rongsheng with refractory

- Q: How much is the highest melting point of silicon?

- . True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. The total volume of heating to 1450 DEG about 1.5~2.2% expansion, the residual expansion will make cutting seam sealing, ensure masonry tightness and good structure strength, so that the brick load softening temperature will reach 1750 degrees Celsius above 1620 degrees in the case of the highest melting point.

- Q: Which material is good for furnace refractory?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick with chromium oxide as its main component has good corrosion resistance, but its thermal shock resistance is poor, and its deformation temperature is lower at high temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, good thermal shock resistance, high strength, resistance to acid and salt corrosion, especially weak acid has good resistance, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Iron scale powder 0.45-0.55%, cement 0.9-1.1%, lime milk 6.5-7.5%, pulp 1.95-2.2%, the silica powder, perlite will be added to the wet mill in proportion, and then add iron scale powder, cement, dry roller 1-2 minutes later

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Silica Lime Bricks for Coke Oven CMAX-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches