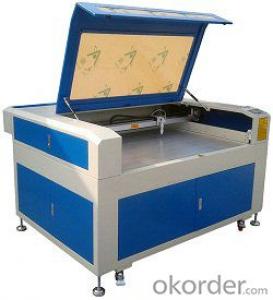

Signkey CO2 Laser Cutter SK-9060L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Standard Features

1.The laser engraver supports all kinds CAD,CORELDRAW professional drawing software to avoid the trouble of exchanging graphs.

2.The special aluminum table reduces the damage to materials by reflected light.

3.The alarming cooling case ensures that the machine works safely.

4.Large memory capacity & possible offline work.

5.It is applicable for cutting and engraving of non-metal materials and we mainly focus on the former. The cutting thickness is 15mm of Acrylics and the result comes good.

Application

DVD/VCD panel processing, artworks making, mould manufacturing, advertisement and decoration, photoelectric film, flexible circuit board and etc.

Specification

Model | 9060L | 1290L |

Machine Size | 2000×1100×1100mm | 2100×1400×1100mm |

Working Area | 900×600mm (3.0×2.0ft) | 1200×900mm( 4.0×3.0ft) |

Laser Tube Power | 60W | 80W |

Power Supply | 60W | 80W |

Laser Strength Control | PWM Control | |

Domestic Made (or Overseas) | ||

Domestic Made (or Overseas) | ||

Knock-down Material | ||

CW 3000 Professional Cooler | ||

Optional | ||

24000mm/min | ||

2500DPI | ||

128M | ||

0.01mm | ||

HPG/BMP/DXF/NC/DWG/PLT | ||

Stepper | ||

Water-cooling and protection system | ||

Wood, bamboo, organic glass, crystal, plastic, garmenrs, paper, leathre, rubber, ceramic, glass and other nonmetal materials | ||

Focus on Scanning, Cutting thickness<5mm | =<20mm | |

Weight

| 350KG | 600KG |

- Q: What kind of mechanical equipment is needed in furniture production?

- See what you want to produce furniture, because the furniture industry is too large, such as hardware furniture, solid wood furniture, furniture panels are corresponding, there are related equipment

- Q: What kind of machine can be used to make panel furniture?

- Again large vertical and horizontal material saw (suitable for engineering cabinet), with less.Edge banding:Hand edge sealing machine, linear edge sealing machinePunching:Three drill row, six row drilling, and then there is a special CNC punching machine(the door panel is different according to the style and the equipment is different.)

- Q: At present, the most advanced furniture production equipment

- For example, a computer panel saw, it is only used for cutting this link, if it is expected to open this link to any comparison can be drawn and saw is the most advanced;

- Q: What kind of woodworking machinery does the solid wood furniture production line need?

- All kinds of furniture production need to use the machines are not the same, we have a woodworking machinery City, you need to have the machinery, and complete, Baidu private letter to me to tell you the address yourself to understand in detail.

- Q: Which furniture manufacturer is good for panel furniture production equipment?

- A CNC cutting machine: 80 thousand, a sealing machine (50 thousand, then the edge machine than the above function, some) a three drill (28 thousand), a total of 158 thousand (the combination of super point, is expected to open on the better)

- Q: What kind of equipment do you need to open a small solid wood furniture factory?

- 1, commonly used equipment:Platform saw, edge sealing machine, cold press, hot press, multi row drill, glue coating machine, band saw, sanding machine, drying room, machine, paint, high-definition spray room.2, wooden furniture is mainly divided into solid wood furniture and panel furniture.

- Q: The eco board needs all those machines to make furniture

- 1 、 aluminum alloy cutting saw. The utility model is used for cutting the aluminum buckle strip of the toilet partition, the clothes hanging rod of the wardrobe, and the lath which can be cut accurately when busy.2, flashlight 1, charging electric drill 1. Use in hand drill, charge, press and install.3, a second-hand drill head. Used to open hinge holes, drilling can also be, but in actual production is not used, need to re adjust the size and influence production.

- Q: What furniture processing equipment does it include?

- Edge sealing machine, as its name suggests, for door or cabinet edge use.

- Q: What kind of machinery is needed for small size furniture production?

- Panel furniture refers to furniture made from MDF or particleboard. A large part of panel furniture is imitation wood grain imitation furniture. At present, some of the panel furniture sold on the market is more and more lifelike, gloss, feel and so on are good, fine workmanship, and plate and hardware parts of good products, prices are also very expensive.

- Q: What are the concrete steps for solid wood furniture? What equipment is used during the period?

- Dry ingredients - wool processing - processing - bending - Glued net material processing - assembly - Part - assembly and finishing (1): dry sheet, wet wood by drying or natural drying, the moisture content of materials is controlled in a certain range, with the use of the furniture area of wood equilibrium moisture content adaptation. The moisture content of other materials used in furniture manufacturing, such as laminated wood, laminated wood and various artificial boards, shall be controlled.

1. Manufacturer Overview

| Location | Anhui, China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Signkey CO2 Laser Cutter SK-9060L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches