SEM919 Motor Grader with ZF Transmission

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 150 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

• Powerful turbocharging , inter-cooler SDEC D9 engine compliance to Stage II emission regulation ,lower fuel consumption.• Reputable new design cooling system meets -40℃ ~ +50℃ extremely harsh working conditions.

• Advanced world-class, electro-hydraulic control power shift (6F/3R) transmission

• High reliable and durable 3-section driven rear axle with limited slip differential.

• Large cab with telescoping controls located on front frame provided good visibility and increased operator comfort , ROPS & FOPS as optional

• World-class variable displacement piston pump ensure continuous matching of hydraulic flow and pressure to power demands, lower fuel consumption.

• Proportional priority pressure compensating (PPPC) valves ensure all cylinders matching with consistent ease of multi-function control, provides precise blade movement and high working efficiency.

• Electro over Hydraulic controlled pin puller and 7 position linkbar design, provides extensive range of blade positioning and ease of operation control from cabin .

• Optimal blade curvature and sufficient throat clearance allows large blade loads and material to roll & flow freely for high work efficiency.

• Unique arch axle design provides maximum clearance when operating over windrowed material, beneficial wheel lean & steering feature improves excellent machine operationalization

• Optional attachment like front blade, ripper & scarifier, snow wing meets diverse customer requirements in term of different work application.

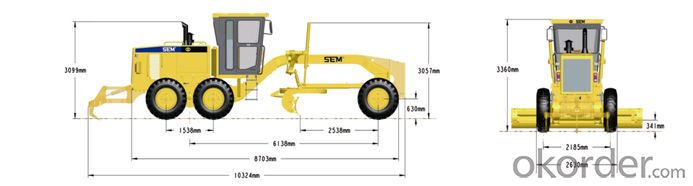

The picture may show product equipped with optional devices

Parameters

| Major Technical Parameters | |

|---|---|

| Machine Weight | 15,070 kg |

| Blade Length | 3974 mm |

| Max. Drawbar Pull | ≥78 kN |

| Engine | |

| Rated Power | 140kW |

| Rated Revs | 2200rpm |

| Model | SDEC |

| Max. Torque | 720 Nm |

| Blade | |

| Max. Lifting Height | 475mm |

| Max. Depth of Cut | 715mm |

| Max. Blade Tip - Forward | 40º |

| Max. Blade Tip - Rear | 5º |

| Tires | |

| Specification | 17.5-25 |

| Hydraulic System | |

| System Pressure | 22 MPa |

| System Characteristics | Load Sensing |

| Steering System | |

| Max. Steering Angle of Front Axle | 47.5° |

| Min. Turning Radius | ≤7.8m |

| Rear Alex/Tandem | |

| Oscillation (Front Up) | 15° |

| Oscillation (Rear Up) | 25° |

| Brake System | |

| Service Brake | Drum Brake |

| Parking Brake | Drum Brake |

| Transmission | |

| Model | 6WG180 |

| Type | Countershaft,EH |

| Max. Speed | 40km/h |

- Q: My washing machine broke down this week, so my wife and I had to trudge down to our local laundromat (this was actually kind of fun - we had the whole place to ourselves and we brought snacks!). We noticed that two of the machines cost extra ($3 instead of $1.50) but were labeled 'triple loaders'. My wife immediately got excited thinking she could finally clean our duvets (our machine at home is too small for them). When we looked at the insides, however, they didn't seem to be any bigger than the regular machines. What's the difference between a regular, a double loader and a triple loader?

- I think the triple-load does not refer to the amount of loundry, but to the soap compartment. With a triple loader, you can add pre-wash soap, main-wash soap, and softener, all the the very beginning, and the machine takes what it needs when it needs it. With a single loader, you have to stand-by and add the chemicals manually at each stage.

- Q: Im going to get one for deer hunting and am wondering if I should get .45 caliber or .50 caliber and how much powder I should use btw this is a flintlock.

- 50 cal are easier to find some states also dont allow .45 for deer with ml so id go for .50 cal

- Q: vs all other actions? Or is it just for fun nowadays?

- It's largely for the tradition, and the expanded season. But a small-bore bullet at high velocity may or may not expand properly when it hits the critter. You can be pretty sure that large, slow ball from a front-stuffer isn't going to shrink before it gets there.

- Q: What Kind Of Hoppers/Loaders Should I Buy For My Tippmann 98 Custom And My Spyder MR1?

- you should buy and empire II hopper because a tippman only shoots semi so just get an average hopper. The empire ii feed 10-12 balls per second so it's not bad for the price, dont buy a good hopper until u get a really good gun.

- Q: Hello, I want to buy a product of Shandong mountain heavy card loader, do not know can not durable, hope you help me...

- Are you a dealer or a customer? I suggest you use the Jinyang brand!

- Q: Besides a round ball, what is the most accurate and powerful round that I can shoot big game with in my 50 caliber muzzle loader?

- A 370 grain Maxi Ball would be best for hunting. For accuracy you'll have to experiment with powder charges. I suggest you start with 75 grains and work your way up in 5 or 10 grain increments. Every black powder rifle is different. For example mine works best with 100 grains. At 105 and 110 the accuracy started to go away.

- Q: How much is the deadweight of the 50 loader of dragon work? There are Shandong, Xiamen, temps, Xugong? I think the introduction on the website generally refers to the quality of the operation of the whole machine. Such as dragon's ZL50C wheel loader. Rated load is 5000kg, the whole machine operation quality 16600kg, then its self-respect should be how much? Thank you

- Generally 16 tons left friend, Liugong have 16.5., there are 16.8!

- Q: We need a new washer/dryer (gas dryer) front end loader is what we have decided to go with. But were having trouble choosing witch model is best for us.We need something for a family of 4 (and growing) something that we could wash our blankets at home instead of going to the local laundry mat would be great! Size, brand ... ?? Any suggestions?

- We bought a Kenmore Elite front end dryer and top loading washer. I can put a full size comforter in that puppy and it gets it real clean. And I can put the equivalent of about 2 of the old loads of laundry in my new one. I love it! It adjusts the water level automatically so you don't waste it too. You can totally adjust the settings if you want but I have always let the washer pick the settings and I haven't ruined anything yet. I have a family of four with two teens -lots of jeans and towels! btw, I read up on the high efficiency ones before we bought this set. There were problems with musty smells and such, so I read. That's why we decided on the traditional washer/dryer.

- Q: i have an empire B loader

- No, if the loader is faster than the gun it is all up to you and your finder speed....

- Q: How many speed loaders do most people who conceal carry revolvers carry with them?How many speed loaders do law enforcement officers back in the day or today who carried revolvers carry?

- That varies. I like revolvers for their large caliber options, mechanical simplicity, ruggedness and reliability. Unfortunately the cylinder width makes a revolver a little large for concealed carry -- especially with summer clothes. I do own speedloaders but I don't use them except for convenience at the firing range. It takes a good deal of practice to be able to use them properly, they make a bulge, and they are completely unnecessary for concealed carry. The way I see it, if you're going to carry a revolver there is little difference in physical size between a small and large caliber revolver -- so you might as well go large. If I need more than 6 shots of .44 mag, there are more than 6 guys and I'm probably toast anyway. I carry what is in the gun only. There is nothing wrong with protecting yourself and loved ones. There is nothing wrong with being prepared. There is a point however where prepared becomes paranoid and eventually paranoid just becomes silly. Seriously, when will you EVER (short of a warzone) need to fight off 5 or 6 men at once if you have a large-caliber revolver? Even if the most ridiculous and improbable set of events occur IN YOUR TOWN (you're concealed carrying, right? You're probably at home) and you end up attacked by a dozen men for some reason, killing two will make the rest rethink their decision. If it doesn't, then your only option is running because they are obviously willing to die to get you. So how many speed loads should you carry for a concealed-carry revolver? Zero. Oh, most of the old police belts had two pouches for speed loaders (at least the one I have does).

Send your message to us

SEM919 Motor Grader with ZF Transmission

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 150 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords