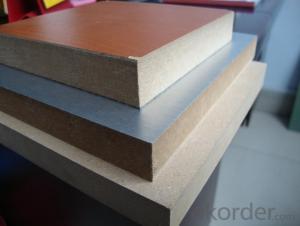

18mm Satin Surface Finish Melamine Faced MDF Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Melamine MDF Board are used for furniture making and house decoration

Characters:

Light, easy to install and disassemble and beautiful.

Products Details:

Detailed Specification:

Product name: Satin Surface Finished Melamine MDF Board

Size: 1220*2440mm

Thickness: 3mm-18mm

length/width tolerance: +/- 0.5mm

thickness tolerance: +/- 0.2mm

glue: E1,E2,E0

moisture: 6~12%

packing: seaworthy export pallet packing,strengthen by steel tape with 3*6 or loose packing in containers

loading quantity: 21.5CBM per 20'container

minimum order quantity: one 20'container

usage: used for furniture

payment term: by T/T or L/C at sight

delivery time: within 20 days after we got your advance payment

2. Packing Details of Melamine Faced MDF Boards

Four sides are around with MDF in thickness ≥4mm,

Top cover is thin MDF in thickness ≥ 8mm,

Bottom board is MDF in thickness ≥12mm ,

4+8 steel strips.

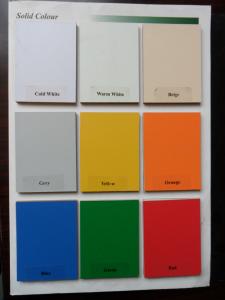

3. Surface Texture of Melamine Faced MDF Boards

Satin, Pearl, Wood Grain, Corrugation.

FAQ:

Q1. How long can we receive the product after purchase?

A1: Normally, cargoes can be shipped within 25days if the paper are in fast-moving colors; however, if colors are special need to be matched, then, we need at least one month to prepare and produce.

- Q: What are the types and usage of interior panels?

- Decorative panels are widely used in the wall, the pillars, furniture, Pass, door, door sets of goods to the site after the use of the best brush before the first varnish to prevent contamination of the board, the need to discuss with the construction manager, A lot of team paint the color of the different methods, some want to color on the floor first, will have been on the varnish after the bad and then the color.

- Q: What is called a panel?

- Three hydrogen ammonia plywood, specifications are: 1.22 * 2.44m, 1.22 * 3m, generally used for furniture or interior decoration!

- Q: What are the quality requirements for decorative panels?

- One: veneer in two kinds: Ma face and smooth, feel good plate flat no bubbles, stickers without broken. Second: the substrate is divided into two categories, MDF and particleboard, a tough degree of environmental protection is difficult to achieve poor water resistance. There are many kinds of wood-based substrate, the substrate is waterproof, the substrate can not have impurities (iron and stone) formaldehyde can not exceed the standard (no pungent odor) see you use dew river plate.

- Q: Is there a difference between paint and plywood?

- The scope of a large number of paint-free panels, plywood is also considered a kind of paint-free, not deceived.

- Q: How to identify the furniture board is good or bad

- See the hardness of the wrench, hardness is also higher that the better the density.

- Q: What kind of glue when you use it?

- White latex (environmental protection is better, and the price is relatively cheap)

- Q: What are the advantages of ecological boards and other boards?

- Consumers in the selection of such plate furniture, in addition to taking into account the color and texture satisfaction, but also from several aspects to identify the appearance of quality: whether stains, scratches, indentation, porosity, color gloss is not uniform, there is no Bubbling phenomenon, with or without local paper tear or defect phenomenon and so on. If the phenomenon of veneering cracking or damage, you can use the following methods to repair: first in the damaged place to put a damp cloth, and then put a hot iron on the hot cloth, forcing the moisture into the veneer, so that the veneer becomes tough and difficult Fragmentation. So that you can first clean the old plastic, and then coated with a layer of milk at the grass layer of wood, and then in the loose surface of the negative coated with a layer of new plastic, compaction, to be completely dry glue.

- Q: Wooden door surface panels (multi-layer board) is a solid wood door or solid wood composite door?

- According to the solid wood doors are not posted, solid wood doors of the process is generally refers to the section, or pure wood.

- Q: How to choose tiles

- Third, the drip test. Can be the water droplets in the back of the tile, watching the water spread after the infiltration of the speed, in general, the slower the water, indicating that the greater the density of the tile; the other hand, the faster water, indicating the density of sparse, the inherent quality of the former is excellent.

- Q: White European furniture oak veneer good or smooth look good

- White furniture on the market are smooth, and good care

Send your message to us

18mm Satin Surface Finish Melamine Faced MDF Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords