Melamine Slotted MDF Board for Furniture Making

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Slotted MDF Board are It is directly used for display board in retail stores and super market, and they are used for furniture making, such as shop fitting, display rack, storage cabinet, garage cabinet

Characters:

Light, easy to install and disassemble and beautiful.

Products Details:

Detailed Specification:

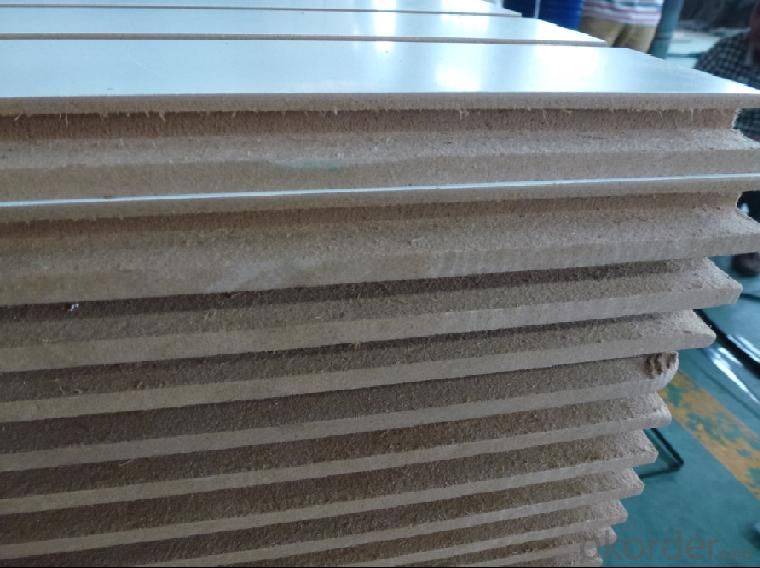

Product name: Slotted Melamine MDF Board

Size: 1220*2440mm

Thickness: 3mm-18mm

length/width tolerance: +/- 0.5mm

thickness tolerance: +/- 0.2mm

Slot Length: 1220mm,2440mm

Slot Distance: 75mm,100mm,150mm,200mm,300mm

Groove type: Rectangle,ellipse,trapezoid.

End side 1: Full groove

End side 2: Half groove(1/2 groove at the top and bottom to allow the panels to be installed one and another without a seam)

Accessories: aluminium bar, thickness is 0.4mm,0.5mm, 0.6mm,0.8mm,1.0mm or customize.

glue: E1,E2,E0

moisture: 6~12%

packing: seaworthy export pallet packing,strengthen by steel tape with 3*6 or loose packing in containers

loading quantity: 21.5CBM per 20'container

minimum order quantity: one 20'container

usage: used for furniture

payment term: by T/T or L/C at sight

delivery time: within 20 days after we got your advance payment

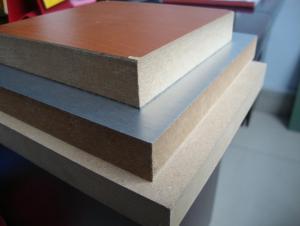

2. Packing Details of Melamine Faced MDF Boards

Four sides are around with MDF in thickness ≥4mm,

Top cover is thin MDF in thickness ≥ 8mm,

Bottom board is MDF in thickness ≥12mm ,

4+8 steel strips.

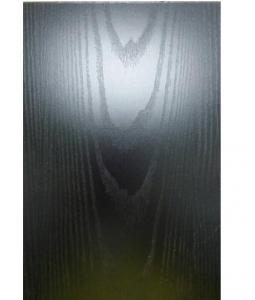

3. Surface Texture of Melamine Faced MDF Boards

Satin, Pearl, Wood Grain, Corrugation.

FAQ:

Q1. How long can we receive the product after purchase?

A1: Normally, cargoes can be shipped within 25days if the paper are in fast-moving colors; however, if colors are special need to be matched, then, we need at least one month to prepare and produce.

- Q:What are the types of wood panel?

- 1. Beech: Scarlet and white beech, can be processed into a plate, square material, thin slices. Texture is fine and straight, or even dotted. Wood hard, tough, resistant to corrosion-resistant impact, easy to crack after drying, transparent paint coating effect is quite good. (Facade) combined with plywood (substrate) for the wall, the column, the staircase handrail, and the various decorative wire (door and window cover, furniture edge, angle, grille, etc.) Face, door and window cover and furniture trim panel

- Q:Do closet, wardrobe board, what plastic good?

- After all, posted a layer of panels, more than a plastic, more pollution sources. There are direct blockboard brush varnish, solid wood side of the edge. Good blockboard texture is also very beautiful!

- Q:Solid wood veneer surface of the veneer how many kinds of materials

- Features for the touch smooth, with your fingers buckle the board has a thick sense of the surface wood clear but not regular, in the corner of the plate can be vaguely see 1 mm or so veneer.

- Q:Plywood hot press and plywood hot press is different

- Uses: veneer press models for neutral furniture factory or small man-made board secondary processing (professional veneer) factory, used for hot pressing adhesive furniture panels, building partitions, wooden doors and in a variety of wood-based panels

- Q:What is the plate? Is it really environmentally friendly?

- Ecological board, sub-narrow and broad two concepts. 1. The general ecological plate is equivalent to the melamine plywood, its full name is melamine impregnated film paper facing wood-based panel, is to have different colors or textures of paper into the eco-board resin adhesive soak, and then dry to a certain degree of curing , Will be paved in the particleboard, moisture board, medium density fiberboard, plywood, blockboard or other hard fiber board surface, made by hot pressing plate.

- Q:Is the wooden door good for solid wood or plywood?

- The surface of the veneer is composed of solid wood door, wood paper layer, primer layer and finish layer. It is characterized in that one surface of wood grain is pasted on the surface of solid wood door and the other surface is connected with primer layer , The topcoat and the primer layer above the connection, composed of solid wood veneer door.

- Q:The difference between eco-board and blockboard

- The carpentry mainly refers to the blockboard commonly known as the big core board, which is made of two pieces of veneer center. Central board is made by the wood side by drying the future, processed into a certain standard of wood, made by the puzzle machine stitching.

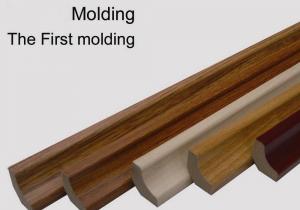

- Q:How many types of wooden lines

- Wood-plastic lines, is the use of domestic booming in recent years, a new type of composite materials, refers to the use of polyethylene, polypropylene and polyvinyl chloride, instead of the usual resin adhesive, and more than 35% -60% , Straw and other waste plant fiber mixed into a new wood material, and then by extrusion processing and output. Mainly used to replace the wood lines and plaster lines.

- Q:Wooden door surface panels (multi-layer board) is a solid wood door or solid wood composite door?

- Is a solid wood composite door. But also look at what is inside. Some doors are densely coated on the board, the middle is the wooden side.

- Q:Bamboo stickers, polymer panels which is good?

- The first point, whether there are children at home, polyester varnish is no matter how good the brand, the last formaldehyde or excessive (I believe that I am doing decoration). Second, the quality of decoration, varnish, mixed oil, plywood (polymer, or paint-free board), varnish quality is definitely the most durable, but also relatively simple

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Melamine Slotted MDF Board for Furniture Making

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords