Wood Sandwich Panels with Rockwool for Sanwhitch Panel House Building Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

House Building Board Rockwool Sandwich Roof Panel

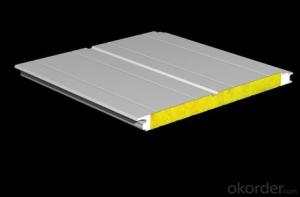

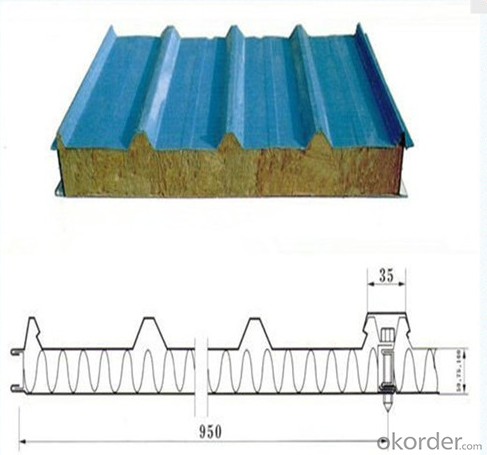

1. Size

Thickness:50/75/100mm

Width:960mm/950mm

Density:80-120kg/m3

2.Product Line

3. Specification

Rock Wool Sandwich Panel | |||

Fireproof grade | Grade A | ||

Density | 120kg/m3 | ||

Steel Thickness | 0.15mm-0.8mm | ||

Effective Width | 950mm 960mm 1150mm | ||

Length | Arbitrary length , according to the transportation ,<12m< span="">

| ||

Zinc Galvanized | 120gr/ m2 Minimum | ||

Paint | 25/7 Micron Polyester Minimum | ||

Density | 120kg/m3 | ||

Temperature Range | -200°C~+ 150°C Specs | ||

Water Absorption Rate | Less than 0.118 | ||

color | Polyester Varnish With Standard Color Shade | ||

Rock Wool Thickness | 50mm | 75mm | 100mm |

Plate Weight KN/m2 | 0.178 | 0.263 | 0.301 |

Heat transfer coefficient W/M2K | 0.749 | 0.530 | 0.411 |

Kcal/m2.h. °C | 0.644 | 0.456 | 0.353 |

Certification | ISO9001:2000 | ||

COMMENT | Qualified. The item tested is in accordance with the national standard of P.R.OF China completely. | ||

4.FAQ

A, The size of the panle can be changed?

Yes. We could product according to your requirement.

B, The rockwoll has fire resistance?

Yes. The fire resistance is Class A.

C, If I want to contact directly with a manager, who can I call?

You can call directly Ms. Carla Wang, phone No. is +86 18511808895.

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- What are the best companies (including imported products) in China?

- Q: Reinforced concrete and metal sandwich board how much difference

- Tower crane driver, scaffolding type of work, all kinds of welding workers

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- 5 cm, 10 cm, 15 cm and 25 cm The general material 5 cm price between 45 to 75 yuan; 75 cm price of 55 to 90 yuan range; 10 cm price of 70 to 100 yuan, Caigang Caigang purification plate thickness can also Custom So we must first understand their choice of materials and thickness, different scenes of the plate is not the same choice

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: How does the wall rock wool sandwich panel be installed?

- All the components are axially connected and the mechanical properties are good , The connection is reliable, the composition of the scaffolding integrity is good, there is no loss of fasteners Construction of the bowl button steel pipe scaffolding from the steel pipe pole, bar, bowl buckle joints and other components 粻 Fu Gang Huang 蕺 number reported copper stem expansion The basic structure and erection requirements and fastener steel scaffolding similar to the difference lies mainly in the bowl buckle joints Bowl buckle joints are made up of the bowl buckle, the next bowl buckle, the bar connector and the bowl buckle limit pin and so on In the pole on the welding under the bowl buckle and bowl buckle on the limit pin, the bowl will be inserted into the pole Weld the plug on the cross bar and the diagonal bar When assembling, insert the crossbar and diagonal bar into the lower bowl, press and rotate the bowl buckle, and use the limit pin to fix the bowl buckle

- Q: Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q: Color steel sandwich board on the price of how much?

- Due to the level of restrictions, there must be inappropriate, hope to add to the same channel or finger scaffolding erection of quality requirements and safety requirements should be organically unified to ensure that the erection process and the subsequent use and removal process of safety and application

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Clamp material, and pressure ah, a little bit of deformation of the clamp will lead to the next time the use of water leakage; some clamp is sealed with rubber ring, pressure, the rubber ring is not fully restored, will lead to Leakage of water; some cases in the pressure, the pipeline to the development of the process of training, but also lead to tight hoop tightly

Send your message to us

Wood Sandwich Panels with Rockwool for Sanwhitch Panel House Building Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords