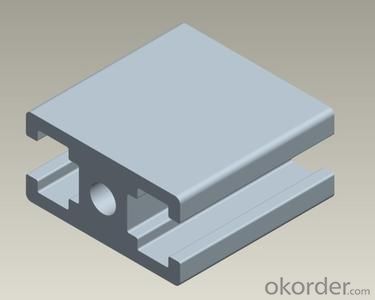

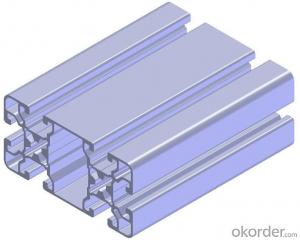

Sandblasting Anodizing Aluminum Alloy Profile Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: This question asks for a list of various uses of aluminum profiles within the construction industry.

- <p>Aluminum profiles have a wide range of applications in the construction industry due to their strength, durability, and lightweight properties. They are used in window and door frames for their resistance to corrosion and ease of maintenance. They are also employed in curtain walls, which are the outer coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are utilized in the construction of scaffolding for their high strength-to-weight ratio, ensuring safety and stability. Additionally, they are used in the manufacturing of modular buildings and prefabricated structures due to their ease of assembly and disassembly. Other applications include roofing systems, flooring structures, and as support beams in various construction projects.</p>

- Q: What are the standards and regulations that control the use of aluminum profiles in construction?

- <p>Yes, there are several standards and regulations that govern the use of aluminum profiles in construction. These include international standards such as ISO 7039 and ISO 8039, which specify requirements for aluminum alloy extruded profiles. In the United States, the American Architectural Manufacturers Association (AAMA) provides guidelines, and the Aluminum Association sets standards for aluminum products. European standards like EN 755 and EN 12206 cover aluminum extrusions for general purposes and structural applications. Compliance with these standards ensures the safety, durability, and performance of aluminum profiles in construction projects.</p>

- Q: Is it possible to utilize aluminum profiles for constructing exterior railings and staircases?

- <p>Yes, aluminum profiles can be used for exterior railings and staircases. They are known for their durability, resistance to corrosion, and low maintenance requirements, making them ideal for outdoor applications. Aluminum's strength and lightweight properties also contribute to its suitability for these structures. However, it's important to ensure that the aluminum is of high quality and properly treated to withstand weather conditions and ensure longevity.</p>

- Q: Is aluminum factory harmful to people?

- But most companies now have the ability to avoid these dangers. Only those illegal backward production capacity will do some damage to the environment for money. These national policies, the city firmly banned the shutting down.

- Q: Identify the key elements to evaluate when choosing aluminum profiles for a particular project.

- <p>When selecting aluminum profiles for a specific project, consider the following factors: 1) Load-bearing capacity, ensuring the profile can support the intended weight and stress; 2) Dimensional stability, to maintain structural integrity over time; 3) Corrosion resistance, especially for outdoor or humid environments; 4) Aesthetics, matching the profile's appearance with the project's design; 5) Cost-effectiveness, balancing quality with budget constraints; 6) Availability of the profile, considering lead times and supply chain reliability; 7) Ease of fabrication and assembly, which can affect construction time and labor costs; 8) Thermal properties, important for energy efficiency in buildings; 9) Compliance with industry standards and regulations; 10) Customizability, for projects with unique specifications or design requirements.</p>

- Q: What are the different surface sandblasting options for aluminum profiles?

- There are several surface sandblasting options for aluminum profiles, including: 1. Aluminum oxide blasting: This involves using aluminum oxide particles to remove surface impurities and create a smooth finish on the aluminum profiles. It is commonly used for cleaning and preparing the surface before further treatments or coatings. 2. Glass bead blasting: Glass beads are used to blast the aluminum surface, which helps to remove oxidation and provide a satin-like finish. This method is often employed for decorative applications or to achieve a specific aesthetic look. 3. Walnut shell blasting: Crushed walnut shells are used as the blasting media to gently remove contaminants and provide a smooth, matte finish on aluminum profiles. It is a non-aggressive option that is suitable for delicate or sensitive surfaces. 4. Steel shot blasting: Steel shot particles are propelled onto the aluminum surface to remove scale, rust, and other imperfections. This method is ideal for heavy-duty cleaning and surface preparation, especially for profiles that will undergo subsequent coatings or treatments. Overall, the choice of sandblasting option for aluminum profiles depends on the desired outcome, surface condition, and the specific requirements of the application.

- Q: Can aluminum profiles be used in railway and transportation infrastructure?

- Yes, aluminum profiles can be used in railway and transportation infrastructure. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and easy fabrication. It can be used in the construction of train bodies, windows, doors, and various structural components. Additionally, aluminum profiles are recyclable, making them environmentally friendly and cost-effective for transportation projects.

- Q: The number of aluminum profiles can be meters or KG. How exactly is it? How do you understand that?

- You see the amount of it, if it is aluminum ingot is certainly in tons to calculate, the profile is, if it is a fixed size, usually 6 meters long. According to the calculated root.The general material company is used to calculate the weight or root. Few meters.

- Q: This question asks if aluminum profiles can be utilized in the construction of environmentally friendly buildings.

- <p>Yes, aluminum profiles can be used for green building applications. They are valued for their durability, recyclability, and energy efficiency. Aluminum is lightweight, which reduces the building's carbon footprint during transportation. It also has excellent thermal conductivity, allowing for better insulation and energy conservation. Additionally, aluminum can be recycled without losing its properties, contributing to a circular economy and reducing waste. These characteristics make aluminum profiles suitable for sustainable construction practices.</p>

- Q: How do you calculate the strength of aluminum profiles?

- In order to determine the strength of aluminum profiles, there are several factors that must be taken into account. Firstly, it is necessary to gather information about the mechanical properties of the aluminum alloy being used, such as its yield strength, ultimate tensile strength, and elastic modulus. This data can be obtained from material data sheets or through testing. Next, the cross-sectional area of the aluminum profile needs to be determined. This can be achieved by measuring the profile's dimensions or referring to its specifications. Generally, the cross-sectional area is calculated by multiplying the profile's width and height. Once the cross-sectional area is known, the applied load on the profile can be calculated. This involves considering the weight or force that will be exerted on the profile. It is important to account for any potential variations or impacts, as the load can be either static or dynamic. With the load and cross-sectional area determined, the stress on the aluminum profile can be calculated using the formula: Stress = Load / Cross-sectional area. This will provide the stress value in units of force per unit area, such as N/m2 or psi. To ensure that the profile's strength is sufficient, a safety factor is typically applied. This accounts for uncertainties in the load calculations and guarantees that the profile can withstand unexpected loads or variations. The magnitude of the safety factor may vary depending on the specific application and industry standards, ranging from 1.5 to 4. By considering these factors and performing the necessary calculations, it is possible to ascertain the strength of aluminum profiles and ensure that they meet the required safety standards for their intended applications.

Send your message to us

Sandblasting Anodizing Aluminum Alloy Profile Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords