Safety Rotary Slip of Type WA-T with API 7K Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Safety Rotary Slip of Type WA-T Description

Safety Rotary Slip are tools for handling flush joint pipe and drill collar. There are three types of safety Rotary Slip:Type WA-T, Type WA-C and Type MP.

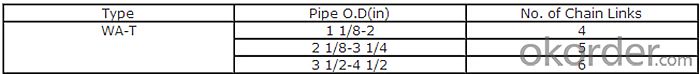

WA-T Safety Clamps can accommodate pipe from 1 1/8 to 4 1/2 O.D.

2. Main Features of Safety Rotary Slip of Type WA-T

1) API standard;

2) Very Good Quality;

3) After-sale Service.

3. Safety Rotary Slip of Type WA-T Images

4. Safety Rotary Slip of Type WA-T Specification

5. FAQ of Safety Rotary Slip of Type WA-T

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class supplier of Mannual Tongs. Our products have been sold to various domestic oilfields and exported to Europe, America, Middle East, Central Asia, North Africa and South-East Asia and other overseas regions.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

We will arrange the delivery as soon as possible after receiving the contract.

- Q: What spare parts does mine machinery equipment have?

- My company with good products, reliable reputation, reasonable prices and warm service, is willing to work with you sincere cooperation, hand in hand, and pioneering and innovative, and seek common development!

- Q: What are the common faults of tower cranes? Removal method

- Tower crane (tower crane) is called tower crane, also known as tower crane, originated in Western europe. A revolving crane mounted on top of a tall tower. The working space is large, mainly used for the vertical and horizontal transportation of materials and the installation of building components during the building construction. It consists of three parts: metal structure, working mechanism and electrical system. The metal structure includes the tower, the boom and the base. The working mechanism has four parts, lifting, luffing, turning and walking. The electrical system consists of motors, controllers, power distribution cabinets, connecting lines, signals and lighting devices, etc..

- Q: China's most powerful mine wear parts

- Wear parts, usually wear plate processing, such as JFE-C400, JFE-C500, DILLIDUR 400V and other imported wear-resistant plate processing parts, long service life, than ordinary wear parts is about ten times higher.

- Q: What are the accessories for mining machinery?

- Bearings, screens for vibrating screens, belts for belts, etc.!! A lot of ah, these are worn parts, what's the problem, ask me again, see the signature on the phone

- Q: What are the accessories for mining machinery?! Mainly refers to?

- Screws, screws, caps, lubricants, gears, belts are things used in mining machinery. Do you understand?

- Q: How to do the maintenance of mining machinery parts?

- Mining machinery belong to large-scale equipment, the purchase of new equipment and frequent replacement parts will consume a lot of money, and affect the enterprise production schedule, therefore, how to correct for mine equipment maintenance so as to prolong the service life of the equipment is very important. The following is the Aupu mining machinery for you to collate how to maintain mechanical parts

- Q: I would like to ask the general mine machinery industry, the purchase of accessories must not go to the original factory to buy?

- Not necessarily, it is best to buy the original factory, after all, they are supporting the production of it!

Send your message to us

Safety Rotary Slip of Type WA-T with API 7K Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches