SAE1008 Steel Wire rod 6.5mm with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 99 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of wire Rod:

wire rod:

Grade:SAE1006B/SAE1008B/SAE1018B

Size:5.5/6.5/7/8/9/10/11/12mm

Festures of wire Rod:

· fasteners, bolts, rivets, screws,

· general purpose wires,

· electrode wires, industrial wires, agriculture wires,

· bush wires, chain rivet wires,

· detonator wire,

· Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

· ACSR wires, earth wires,

· tyre and hose reinforcement wires

· prestressed concrete wire, springs and rope wires,

· card clothing wires,

· vineyard wires,

Specifications of wire Rod:

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | Cr | |

SAE1006B | 0.03~O.07 | ≤0.32 | ≤0.30 | ≤0.045 | ≤0.040 | 0.3-0.35 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

250-280 | 350-380 | ≥32 | ||||

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | Cr | |

SAE1008B | 0.10max | 0.3~O.50 | 0.15max | 0.050max | 0.040 max | 0.3-0.35 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

≥195 | 315-430 | ≥30 | ||||

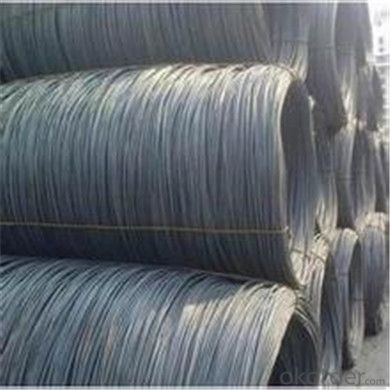

Images of wire Rod:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How is steel wire rod used in the production of fencing?

- Steel wire rod is used in the production of fencing as the primary material for creating wire mesh, which is commonly used in various types of fencing. It is also used to reinforce and strengthen the structure of the fencing panels, ensuring durability and security.

- Q: What are the cost considerations of steel wire rod?

- The cost considerations of steel wire rod include the price of raw materials, production and processing costs, transportation and logistics expenses, market demand and competition, and any additional charges or tariffs. Factors such as the quality, grade, diameter, and quantity of steel wire rod can also affect the overall cost.

- Q: What are the different heat treatments applied to steel wire rod?

- Some of the different heat treatments applied to steel wire rod include annealing, quenching and tempering, normalizing, and case hardening.

- Q: What are the different types of steel wire rod finishes for improved impact resistance?

- There are several types of steel wire rod finishes that can improve impact resistance. Some common finishes include galvanized, epoxy coated, and zinc-coated finishes. These finishes provide a protective layer that enhances the durability and strength of the wire rod, making it more resistant to impacts and potential damage.

- Q: How is steel wire rod used in the manufacturing of wire for automotive seat belts?

- Steel wire rod is a crucial component in the manufacturing of wire for automotive seat belts. It is used as the primary material for the wire due to its exceptional strength and durability. The wire rod undergoes a series of processes to transform it into the final wire used in seat belts. Firstly, the steel wire rod is carefully selected based on its specific properties, such as tensile strength and flexibility. The rod is typically made from high-carbon steel, which ensures it can withstand the intense forces applied during accidents. The selected steel wire rod is then subjected to a process called cold drawing. This process involves reducing the diameter of the rod by pulling it through a series of dies, resulting in a thinner, more uniform wire. Cold drawing helps to enhance the wire's strength and improve its surface finish. After cold drawing, the wire is usually coated with a layer of zinc through a process called galvanization. This coating serves as a protective barrier against corrosion, ensuring that the wire remains strong and reliable over time, even in harsh environments. The coated wire is then further processed to meet the specific requirements of automotive seat belts. It is typically wound onto spools or bobbins, ready to be fed into the seat belt manufacturing machines. In the seat belt assembly process, the wire is cut to the desired length and threaded through the seat belt webbing. The wire provides the necessary strength and support to the seat belt, ensuring it can effectively restrain passengers during sudden stops or accidents. Overall, the use of steel wire rod in the manufacturing of wire for automotive seat belts plays a vital role in ensuring the safety and reliability of these critical safety devices. The exceptional strength, durability, and corrosion resistance of the steel wire rod make it an ideal material for seat belt production, providing peace of mind to both manufacturers and consumers alike.

- Q: What are the different types of steel wire rod coatings used for electrical conductivity?

- Various types of coatings are used for electrical conductivity in steel wire rods, each with their own distinct characteristics and advantages. Copper is a commonly used coating for electrical conductivity. It possesses excellent electrical conductivity properties, making it an ideal choice for applications that require high electrical performance. Copper coatings can be applied using methods such as electroplating or hot-dipping, ensuring a uniform and durable coating on the steel wire rod. Silver is another coating used for electrical conductivity. It is known for its exceptional electrical conductivity, surpassing even that of copper. It is often utilized in applications that demand the highest level of electrical performance, such as high-frequency cables or precision electronic components. Silver coatings can be applied through electroplating or electroless plating processes, resulting in a thin and highly conductive layer on the steel wire rod. Zinc, although it may not possess the same level of conductivity as copper or silver, is also a commonly used coating for electrical conductivity. Zinc coatings are frequently employed for corrosion protection in electrical applications, as they create a sacrificial layer that prevents the underlying steel wire rod from corroding. Additionally, zinc coatings can enhance the electrical conductivity of the steel wire rod to some extent. Tin coatings are utilized for electrical conductivity as well. Tin is known for its low electrical resistance and good corrosion resistance properties. Tin coatings can be applied through electroplating or hot-dipping processes, resulting in a reliable and conductive layer on the steel wire rod. There are also specialized coatings, such as nickel or gold, that can be used for specific applications requiring unique electrical conductivity properties. Nickel coatings offer good electrical conductivity and corrosion resistance, making them suitable for various electrical and electronic applications. Gold coatings, on the other hand, are highly conductive and provide excellent corrosion resistance, making them ideal for high-end electronic components or connectors. In conclusion, the coatings used for electrical conductivity in steel wire rods encompass copper, silver, zinc, tin, nickel, and gold. Each of these coatings offers specific advantages and is selected based on desired electrical performance, corrosion resistance, and application requirements.

- Q: How are steel wire rods used in the manufacturing of wire baskets for storage and organization?

- Steel wire rods are used in the manufacturing of wire baskets for storage and organization by being shaped and woven into the desired basket structure. The rods provide strength and durability to the baskets, allowing them to hold various items securely. Additionally, they can be coated or galvanized to prevent rusting, ensuring longevity.

- Q: How is steel wire rod used in the manufacturing of tire cords?

- Steel wire rod is used in the manufacturing of tire cords by being processed into high-tensile steel wires. These wires are then coated and twisted together to form a strong and durable cord that provides reinforcement and stability to the tire. The tire cords made from steel wire rod enhance the overall strength and resilience of the tire, making it capable of withstanding high pressures and providing better grip and control on the road.

- Q: How is the inclusion content of steel wire rod determined?

- The inclusion content of steel wire rod is determined through various methods and techniques. One common approach is the use of microscopic analysis, where a sample of the wire rod is examined under a microscope to identify and quantify the inclusions present. The sample is typically prepared by cutting a small section of the wire rod and mounting it on a microscope slide. This allows for a clear and detailed view of the inclusions. The sample is then polished and etched to reveal the inclusions more clearly. Under the microscope, the inclusions can be categorized based on their size, shape, and composition. They can range from small particles to larger clusters, and can be identified as oxides, sulfides, or other types of impurities. Quantifying the inclusion content involves counting the number of inclusions present in a given area or volume of the sample. This can be done manually by counting each inclusion, or by using automated image analysis software that can detect and count the inclusions. In addition to microscopic analysis, other techniques such as scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) can be employed to further analyze the inclusions and determine their elemental composition. The inclusion content of steel wire rod is an important quality parameter, as excessive inclusions can negatively affect the mechanical properties and performance of the final product. Therefore, accurate determination of the inclusion content is crucial for ensuring the quality and reliability of the steel wire rod.

- Q: How is steel wire rod tested for quality control?

- Steel wire rod is tested for quality control through a series of rigorous inspections and tests. These include visual inspections to check for any surface defects, dimensional measurements to ensure the wire rod meets specified size and shape requirements, and chemical composition analysis to verify the desired levels of various elements. Mechanical tests, such as tensile and hardness tests, are conducted to assess the strength and durability of the wire rod. Additionally, non-destructive tests like ultrasonic or magnetic particle inspections are performed to identify any internal flaws or discontinuities. These comprehensive testing methods ensure that steel wire rods meet the highest quality standards before being used in various applications.

Send your message to us

SAE1008 Steel Wire rod 6.5mm with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 99 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords