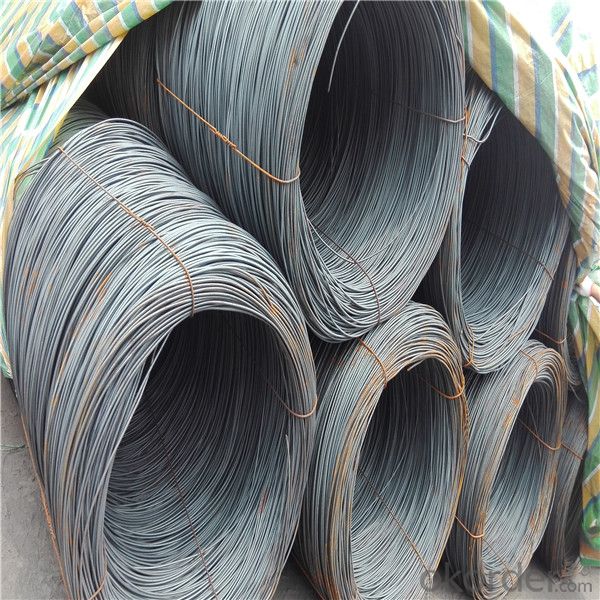

SAE1008 Steel wire rod 5.5mm-14mm low carbon

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 17645 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Produced from billets at the rolling mill, wire rod is the basis of all steel wire, rope and fencing products.

The most important characteristic in determining wire rod’s end use is its drawability. Common low carbon

wire rod is used for nails, small shaped products, barbed wires, various wire nettings, steel chains, and

other applications. High Carbon wire rod uses include steel tire cords for automobiles, conveyor belts, and

pressure hoses. Other applications include bolts, nuts, and machine parts, as well as compression, tension

and torsion springs.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale,

easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

It generally used in braiding the hose for bathing product and machinery. With it

good flexibility, resistant to high temperature and resistant to corrosion, it

used widely in many industries.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the main distribution channels for steel wire rod?

- The main distribution channels for steel wire rod include direct sales to manufacturers, wholesalers, and distributors.

- Q: How is steel wire rod used in the manufacturing of wire forms for HVAC systems?

- Wire forms for HVAC systems depend on steel wire rod as a crucial element in their manufacturing process. These wire forms play a vital role in providing structural support and stability to the HVAC system. To begin with, the actual wire used in wire forms is produced using steel wire rod. This rod is typically made from high-quality steel, ensuring that the resulting wire is strong and durable. The rod then goes through various manufacturing techniques, such as drawing, annealing, and coating, to achieve the desired wire diameter and properties. Once the wire is formed, it can be used in different ways within HVAC systems. For example, it can be employed to create wire forms that serve as support structures for air ducts. These wire forms establish a robust framework that maintains the shape and integrity of the ductwork. Furthermore, steel wire rod can be utilized to manufacture wire forms that act as reinforcement for HVAC components. For instance, wire grids can be made to support air filters, enhancing their structural stability and preventing collapse under pressure. Wire forms made from steel wire rod can also serve as fasteners or connectors within HVAC systems. They can be shaped into hooks, clips, or springs that securely hold various components together, ensuring a reliable connection. The incorporation of steel wire rod in the manufacturing of wire forms for HVAC systems offers several advantages. Steel's strength and durability make it an ideal material for withstanding the harsh conditions encountered in HVAC applications. Moreover, its excellent corrosion resistance ensures the longevity of wire forms in diverse environments. In conclusion, steel wire rod is an essential material in the manufacturing of wire forms for HVAC systems. Its strength, durability, and versatility make it a suitable choice for creating wire forms that provide structural support, reinforcement, and fastening mechanisms within HVAC systems.

- Q: How does the tensile strength of steel wire rod vary with different heat treatment processes?

- The heat treatment process applied can greatly impact the tensile strength of steel wire rod. Various heat treatment processes, including annealing, normalizing, quenching, and tempering, can have a profound influence on the wire rod's tensile strength. Annealing is a process where the steel wire rod is heated to a specific temperature and then slowly cooled. This helps alleviate internal stresses and enhance the wire rod's ductility. Consequently, the tensile strength decreases, but the elongation and overall toughness improve. On the contrary, normalizing involves heating the steel wire rod to a higher temperature than annealing, followed by cooling in still air. This refines the grain structure, enhancing both strength and hardness. The tensile strength increases, but there may be a slight decrease in ductility and toughness. Quenching is a rapid cooling process that entails immersing the steel wire rod in a quenching medium, like oil or water, after heating it to a high temperature. This leads to the formation of a strong and hard structure known as martensite. Consequently, the tensile strength significantly increases, but ductility decreases substantially. Lastly, tempering involves reheating the quenched wire rod to a lower temperature and then slowly cooling it. This helps relieve internal stresses and reduce brittleness caused by quenching. Therefore, the tensile strength slightly decreases, but ductility and toughness improve. To summarize, different heat treatment processes have varying effects on the tensile strength of steel wire rod. Annealing decreases tensile strength but improves ductility; normalizing increases tensile strength while slightly reducing ductility; quenching significantly increases tensile strength but decreases ductility; tempering slightly reduces tensile strength while improving ductility. Hence, the choice of heat treatment process must be carefully considered based on the desired properties of the steel wire rod.

- Q: What are the common machining methods for steel wire rod?

- Some common machining methods for steel wire rod include turning, drilling, milling, and threading.

- Q: What are the common production processes for helium-coated steel wire rod?

- The common production processes for helium-coated steel wire rod include wire drawing, cleaning and coating, annealing, and spooling.

- Q: How is steel wire rod used in the manufacturing of wire forms for communication cables?

- Steel wire rod is an essential component in the manufacturing process of wire forms for communication cables. The steel wire rod serves as the base material from which wires are manufactured. After the steel wire rod is obtained, it undergoes a series of processes to transform it into wire forms suitable for communication cables. Firstly, the steel wire rod is cleaned and inspected for any defects or impurities. This ensures that the resulting wire forms are of the highest quality and meet the required standards. Once cleaned, the steel wire rod is then heated to a specific temperature and passed through a series of dies. This process, known as drawing, reduces the diameter of the wire rod while increasing its length. After the drawing process, the steel wire rod is further processed to enhance its mechanical properties. This may include annealing, a heat treatment process that increases the wire's flexibility and reduces its brittleness. Additionally, the wire may undergo various surface treatments to improve its resistance to corrosion or to provide insulation. Once the wire forms are manufactured, they are used in the production of communication cables. These wire forms can be used as conductive elements within the cables, allowing the transmission of electrical signals. The wire forms may also be utilized as structural components, providing strength and support to the cables. In the manufacturing of communication cables, the steel wire rod ensures the production of high-quality wire forms that meet the specific requirements of these cables. The durability, flexibility, and conductivity of the wire forms contribute to the efficient and reliable transmission of information through the communication cables.

- Q: What are the different packaging materials used for steel wire rod?

- There are several different packaging materials commonly used for steel wire rods. These materials are chosen based on factors such as the length and weight of the wire rods, the level of protection required during transportation, and the ease of handling for both the manufacturer and the end user. Here are some of the most commonly used packaging materials for steel wire rods: 1. Steel Coils: One of the most popular packaging options for steel wire rods is to bundle them into coils. The wire rods are wound tightly into a coil shape using a winding machine. This method provides a compact and secure packaging solution, making it easy to transport and handle the wire rods. 2. Wooden Reels: For longer and heavier wire rods, wooden reels are often used. The wire rods are wound around a wooden reel, providing a larger and more stable packaging option. Wooden reels are commonly used for wire rods that are used in construction and industrial applications. 3. Pallets: Another packaging option for steel wire rods is to stack them on wooden or plastic pallets. This method provides a stable base for the wire rods and allows for easy handling using forklifts or pallet jacks. Pallets are commonly used for bulk shipments of wire rods. 4. Cardboard Boxes: Smaller wire rods or wire rods with specific length requirements may be packaged in cardboard boxes. These boxes provide protection against damage during transportation and allow for easy handling and storage. 5. Plastic Wraps: In some cases, steel wire rods may be packaged using plastic wraps. This method is often used for smaller quantities or when the wire rods need to be protected from moisture or dust during transportation. It is important to note that the choice of packaging material may vary depending on the specific requirements of the wire rod manufacturer and the end user. Factors such as cost, transportation method, and storage conditions can also influence the selection of packaging materials.

- Q: What are the common production processes for hydrogen-coated steel wire rod?

- The common production processes for hydrogen-coated steel wire rod include pickling, drawing, coating with hydrogen, and annealing.

- Q: What are the common production processes for californium-coated steel wire rod?

- The common production processes for californium-coated steel wire rod typically involve several steps. First, the steel wire rod is cleaned and treated to remove any impurities or contaminants. This may include processes such as pickling, shot blasting, or acid treatment. Next, a layer of californium is applied to the surface of the steel wire rod. This can be done through various methods, such as physical vapor deposition (PVD), chemical vapor deposition (CVD), or electroplating. The californium coating is carefully controlled to ensure a uniform and consistent thickness. Once the californium coating is applied, the steel wire rod may undergo additional processes to enhance its properties. This can include heat treatment, annealing, or quenching to improve its strength, hardness, or other desired characteristics. Finally, the californium-coated steel wire rod is inspected for quality assurance purposes. This may involve visual inspection, dimensional measurements, or testing for adherence to specific standards or specifications. Overall, the production processes for californium-coated steel wire rod aim to ensure a high-quality product with the desired properties and performance.

- Q: What are the different types of steel wire rod surface defect evaluation criteria?

- There are several different types of steel wire rod surface defect evaluation criteria used in the industry. Some of the commonly used criteria include visual inspection, dimensional measurement, and non-destructive testing methods such as ultrasonic testing, magnetic particle testing, and eddy current testing. These criteria are used to identify and classify defects such as surface cracks, pits, scratches, and deformations in the wire rod surfaces, ensuring the quality and integrity of the product.

Send your message to us

SAE1008 Steel wire rod 5.5mm-14mm low carbon

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 17645 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords