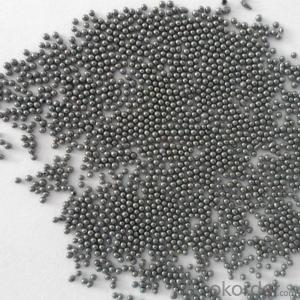

S70-S780 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Description:

1.18 years on metal abrasives manufacturing and exporting.

2. Delivery within 15 days.

3. Full transport insurance.

4. Sell to 32 countries on 5 continents.

Product Picture:

Size:

S780, S660, S550, S460, S390, S330, S280, S230, S170, S110, S70

Chemistry Composition:

| C | Mn | Si | S | P |

| 0.70-1.20% | 0.60-1.20% | 0.40-1.20% | ≤0.05% | ≤0.05% |

Average degree of hardness:

| Normal | 40-50HRC (377-509HV) |

| Special | 52-56HRC (543-620HV) |

| Special | 56-60HRC (620-713HV) |

| Minimum density | 7.4g/cm3 |

Package:

25kgs/bag, 40bags/ton/pallet

1000kgs/ton bag

Product Standard:

American automobile engineer's association "SAE J827Cast steel shot standard"

Product use:

Cast steel shot is wildly used for cleaning the rust of metal surface and the reinforced of metal parts. Such as Foundry Industry, Shipbuilding Industry, Container Industry, Marble Cutting, Petroleum Pipeline, Automotive Industry etc.

| Cast Steel Shot Grain the degree distribute | ||||||||||||

| The eyes count | mm | sizes | ||||||||||

| 2.5 | 2.0 | 1.7 | 1.4 | 1.2 | 1.0 | 0.8 | 0.6 | 0.5 | 0.3 | 0.2 | ||

| 7 | 2.80 | all pass | ||||||||||

| 8 | 2.36 | all pass | ||||||||||

| 10 | 2.00 | 85% min | all pass | all pass | ||||||||

| 12 | 1.70 | 97% min | 85% min | 5% max | all pass | |||||||

| 14 | 1.40 | 97% min | 85% min | 5% max | all pass | |||||||

| 16 | 1.18 | 97% min | 85% min | 5% max | all pass | |||||||

| 18 | 1.00 | 96% min | 85% min | 5% max | all pass | |||||||

| 20 | 0.850 | 96% min | 85% min | 10% max | all pass | |||||||

| 25 | 0.710 | 96% min | 85% min | 10% max | ||||||||

| 30 | 0.600 | 96% min | 85% min | all pass | ||||||||

| 35 | 0.500 | 97% min | 85% min | 10% max | ||||||||

| 40 | 0.425 | 97% min | all pass | |||||||||

| 45 | 0.355 | 80% min | 10% max | |||||||||

| 50 | 0.300 | 90% min | ||||||||||

| 80 | 0.180 | 80% min | ||||||||||

| 120 | 0.125 | 90% min | ||||||||||

| 200 | 0.075 | |||||||||||

| 325 | 0.045 | |||||||||||

| SAE Standard | S-780 | S-660 | S-550 | S-460 | S-390 | S-330 | S-280 | S-230 | S-170 | S-110 | S-70 | |

- Q: What are the different types of steel wire products?

- There are several different types of steel wire products, including steel wire ropes, steel wire mesh, steel wire cables, steel wire springs, and steel wire fencing.

- Q: What are the different types of steel sheets and their applications?

- There are several different types of steel sheets, each with their own unique properties and applications. Some common types include cold rolled steel sheets, hot rolled steel sheets, galvanized steel sheets, and stainless steel sheets. Cold rolled steel sheets are known for their smooth finish and high strength, making them ideal for applications such as automotive parts, appliances, and construction materials. Hot rolled steel sheets are less smooth but have a higher tolerance for shaping and bending, making them suitable for structural components, machinery, and pipe manufacturing. Galvanized steel sheets are coated with a layer of zinc to protect against corrosion, making them commonly used in outdoor structures, roofing, and automotive body parts. Stainless steel sheets are highly resistant to corrosion and staining, making them popular in applications such as kitchen equipment, medical instruments, and architectural features. Overall, the choice of steel sheet type depends on the specific requirements of the application, including strength, durability, corrosion resistance, and desired aesthetic.

- Q: What are the applications of steel in the food processing industry?

- Steel is widely used in the food processing industry due to its durability, hygiene, and resistance to corrosion. It is utilized in various applications such as food storage containers, processing equipment, conveyor belts, and cutting tools. Steel's ability to withstand high temperatures and easy cleaning make it ideal for maintaining food safety standards and ensuring the efficiency of food processing operations.

- Q: What are the different types of steel fasteners and their uses in the marine industry?

- There are several types of steel fasteners commonly used in the marine industry. Some of the most common ones include stainless steel bolts, screws, and nuts. These fasteners are highly resistant to corrosion, making them ideal for use in marine environments where they are exposed to saltwater and moisture. They are often used to secure various components of a boat or ship, such as railings, cleats, and fittings. Additionally, steel fasteners like snap hooks and shackles are used to connect ropes and chains, providing reliable and secure connections in the marine industry.

- Q: What are the common types of steel products used in the pet photography and videography industry?

- In the pet photography and videography industry, some common types of steel products used include tripods, camera mounts, light stands, and backdrop support systems. These steel products provide stability and durability, ensuring steady shots and capturing the perfect moments with pets.

- Q: How is steel used in the production of packaging materials?

- Steel is commonly used in the production of packaging materials due to its strength, durability, and recyclability. It is used to create cans, containers, and lids that can safely hold and preserve various products, such as food, beverages, and chemicals. Steel packaging provides excellent protection against moisture, light, and air, ensuring product integrity and extending shelf life. Additionally, steel is highly sustainable as it can be recycled indefinitely, making it an environmentally friendly choice for packaging materials.

- Q: What are the properties of tool steel for precision cutting tools?

- Tool steel for precision cutting tools typically has several important properties: 1. Hardness: Tool steels used for precision cutting tools are known for their high hardness. This allows the tools to retain their sharp cutting edges, even when subjected to high temperatures and repeated use. 2. Wear resistance: Precision cutting tools are often subjected to abrasive materials and high-speed cutting operations. Tool steels with good wear resistance properties can withstand these conditions and maintain their cutting performance over extended periods. 3. Toughness: While hardness is crucial, tool steels for precision cutting tools also need to have a certain level of toughness. This allows the tools to withstand impacts, shocks, and vibrations without chipping or breaking. 4. Heat resistance: Precision cutting tools can generate significant heat during cutting operations. Tool steels with good heat resistance properties can withstand these high temperatures without losing their hardness or temper. 5. Corrosion resistance: Precision cutting tools may be exposed to various corrosive environments, such as oils, coolants, or moisture. Tool steels with good corrosion resistance properties can prevent rusting and maintain their cutting performance. Overall, tool steels for precision cutting tools need to strike a balance between hardness, wear resistance, toughness, heat resistance, and corrosion resistance to ensure optimal cutting performance and longevity.

- Q: What are the different types of steel products used in the manufacturing of gardening tools?

- There are various types of steel products used in the manufacturing of gardening tools, including stainless steel, carbon steel, and alloy steel. Stainless steel is popular due to its resistance to corrosion and rust, making it ideal for tools exposed to moisture. Carbon steel is durable and can be heat-treated for added strength, commonly used for blades and pruning tools. Alloy steel, a blend of different metals, offers a combination of strength, durability, and resistance to wear and tear, making it suitable for heavy-duty gardening tools.

- Q: What are the advantages of using steel in automotive manufacturing?

- There are several advantages of using steel in automotive manufacturing. Firstly, steel is known for its exceptional strength and durability, making it ideal for withstanding the harsh conditions and stresses experienced by vehicles. This helps ensure the safety of passengers and enhances the overall structural integrity of the vehicle. Additionally, steel's malleability allows for complex shaping, enabling manufacturers to create intricate designs and improve aerodynamics. Moreover, steel is readily available and cost-effective compared to alternative materials, making it a practical choice for mass production. Lastly, steel is highly recyclable, contributing to sustainability efforts and reducing the environmental impact of automotive manufacturing.

- Q: What are the applications of steel in the mining industry?

- Steel is widely used in the mining industry for various applications including mining equipment, infrastructure, and structural components. It is used in the construction of mining machinery such as drills, excavators, and trucks due to its high strength and durability. Steel is also used in the fabrication of mine shafts, storage tanks, and pipelines for transporting minerals. Additionally, steel is used in the construction of mine buildings, bridges, and other structures required for mining operations. Overall, steel plays a crucial role in the mining industry by providing robust and reliable materials for equipment and infrastructure.

Send your message to us

S70-S780 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords