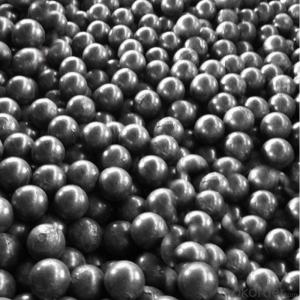

G10-G120 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Product Description:

1.18 years on metal abrasives manufacturing and exporting.

2. Delivery within 15 days.

3. Full transport insurance.

4. Sell to 32 countries on 5 continents.

Product Picture:

Size:

S780, S660, S550, S460, S390, S330, S280, S230, S170, S110, S70

Chemistry Composition:

| C | Mn | Si | S | P |

| 0.70-1.20% | 0.60-1.20% | 0.40-1.20% | ≤0.05% | ≤0.05% |

Average degree of hardness:

| Normal | 40-50HRC (377-509HV) |

| Special | 52-56HRC (543-620HV) |

| Special | 56-60HRC (620-713HV) |

| Minimum density | 7.4g/cm3 |

Package:

25kgs/bag, 40bags/ton/pallet

1000kgs/ton bag

Product Standard:

SAE J827

We press American Cast steel association strictly"SFSA20-66 The Cast steel whets to anticipate the standard", American automobile engineer's association"SAE J1993Cast Steel GritThe standard", the People's Republic of China black metallurgy profession"YB/T5150-1993Cast Steel GritThe standard", the American soldier mark"MIL-S -851CTidy up and enhance to use the metals steel sand and the steel pill"and the nations standardize organization" ISO11124-3High carbon Cast steel pillCast Steel Grit Standard"the future life produce.

Product use:

Cast steel shot is wildly used for cleaning the rust of metal surface and the reinforced of metal parts. Such as Foundry Industry, Shipbuilding Industry, Container Industry, Marble Cutting, Petroleum Pipeline, Automotive Industry etc.

- Q:What are the different types of steel rails and their applications in the railway industry?

- There are primarily three types of steel rails used in the railway industry: plain carbon steel rails, head-hardened rails, and composite rails. Plain carbon steel rails are the most common type and are widely used for general railway tracks. They offer good strength, durability, and affordability, making them suitable for most applications. Head-hardened rails are heat-treated to increase their hardness and wear resistance. These rails are commonly used in high-speed and heavy-haul tracks where the forces and wear are more significant. Head-hardened rails reduce the maintenance requirements and offer a longer lifespan compared to plain carbon steel rails. Composite rails are a combination of different materials, typically steel and other alloys. These rails are used in specific situations where additional properties are required, such as increased strength, reduced noise, or improved resistance to extreme temperatures. Overall, the choice of steel rail depends on factors like the expected traffic load, speed, and environmental conditions. The railway industry carefully selects the appropriate type of steel rail to ensure safe and efficient operations.

- Q:What are the different types of steel mesh and their applications?

- There are several types of steel mesh used for various applications. Welded wire mesh is commonly used in construction for reinforcing concrete structures and fencing. Expanded metal mesh is suitable for industrial applications such as walkways, security screens, and ventilation panels. Woven wire mesh is used for filtration, sieving, and separation in industries like mining, agriculture, and food processing. Additionally, stainless steel mesh is corrosion-resistant and often employed in architectural projects, sieving applications, and as a safety measure in windows and doors.

- Q:What are the different types of steel coatings for fire resistance?

- There are several types of steel coatings used for fire resistance, including intumescent coatings, cementitious coatings, and epoxy coatings. Intumescent coatings are designed to expand and form a protective barrier when exposed to high temperatures, providing insulation and delaying the spread of fire. Cementitious coatings are made of cement and other additives that provide fire resistance by forming a solid protective layer when exposed to heat. Epoxy coatings are primarily used for corrosion protection but can also provide some level of fire resistance due to their ability to prevent the spread of flames and heat transfer.

- Q:How is steel used in the production of wind turbine towers?

- Steel is commonly used in the production of wind turbine towers due to its strength, durability, and ability to withstand harsh weather conditions. The towers are typically constructed using sections of steel that are bolted or welded together, providing the necessary height and stability for the wind turbine to operate efficiently. The steel also acts as a support structure for other components such as the nacelle and rotor, ensuring the overall stability and safety of the wind turbine.

- Q:How do steel products withstand extreme temperatures and weather conditions?

- Steel products are able to withstand extreme temperatures and weather conditions due to their inherent strength and durability. Steel has a high melting point, making it resistant to heat, and its composition allows it to maintain its structural integrity under severe weather conditions such as strong winds, heavy snow, or intense rain. Additionally, steel can be coated with protective layers such as galvanization or paint, which further enhances its resistance to corrosion and rust.

- Q:What are the different types of steel profiles used in architectural designs?

- There are several types of steel profiles commonly used in architectural designs, including I-beams, C-channels, angle iron, T-sections, and hollow structural sections (HSS). These profiles are utilized for their structural strength, versatility, and ability to support heavy loads in various architectural applications.

- Q:How is steel used in the manufacturing of elevators and escalators?

- Steel is used extensively in the manufacturing of elevators and escalators due to its strength, durability, and load-bearing capabilities. It is utilized in various components such as the elevator car, support structures, guide rails, and escalator steps. The steel framework provides the necessary stability, while its corrosion resistance ensures a long lifespan for these transportation systems.

- Q:What are the different types of steel fasteners used in construction?

- There are several different types of steel fasteners commonly used in construction, including bolts, screws, nails, and rivets. These fasteners are essential for joining various components together, providing strength and stability to structures. Bolts are typically used for heavy-duty applications, while screws are versatile and can be used in multiple construction projects. Nails are commonly used for fastening wood materials, and rivets are frequently used to join metal components together. Each type of steel fastener has its own unique characteristics and uses, ensuring that construction projects are secure and durable.

- Q:How is steel used in the production of agricultural machinery and equipment?

- Steel is used extensively in the production of agricultural machinery and equipment due to its strength, durability, and versatility. It is used to construct the frames, bodies, and components of various agricultural machines such as tractors, harvesters, plows, and irrigation systems. Steel's robust nature allows these machines to withstand harsh environments, heavy loads, and repetitive use, ensuring they can operate efficiently for long periods. Additionally, steel can be easily shaped and welded, making it ideal for creating complex and custom parts required in agricultural equipment.

- Q:What are the advantages of using steel wire?

- There are several advantages of using steel wire. Firstly, steel wire is incredibly strong and durable, making it suitable for a wide range of applications. It can withstand heavy loads, resist deformation, and maintain its structural integrity over time. Secondly, steel wire has high tensile strength, meaning it can withstand pulling forces without breaking. This makes it ideal for use in industries such as construction, automotive, and manufacturing. Additionally, steel wire is resistant to corrosion, which increases its lifespan and reduces maintenance costs. Lastly, steel wire is flexible and versatile, allowing it to be easily shaped and manipulated for various purposes. Overall, the advantages of using steel wire include its strength, durability, resistance to corrosion, and versatility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

G10-G120 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords