Thermal Insulation Rubber Tube and Pipe with Insulation Rubber Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

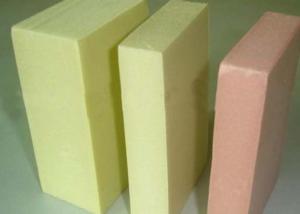

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is polystyrene a polycyclic aromatic? Is not all the hydrocarbon chemical products are carcinogenic, such as the production of foam raw materials: polystyrene

- This is a lot, but do you say the site is the construction site?

- Q: This question is asking for instructions on how to clean and store aluminum foil rolling film to maintain its quality and usability.

- <p>To clean aluminum foil rolling film, gently wipe it with a damp cloth to remove any residue. Avoid using abrasive materials that could scratch the surface. After cleaning, let it dry completely. To store, roll the film tightly and wrap it in a protective layer, such as a plastic wrap or a clean cloth, to prevent dust and scratches. Store it in a cool, dry place away from direct sunlight to maintain its integrity.</p>

- Q: What are the safety regulations or guidelines that aluminum foil facing must adhere to?

- <p>Safety standards for aluminum foil facing are crucial to ensure the product's safety and effectiveness. These standards typically include requirements for material composition, thickness, and bonding strength to ensure the foil's durability and resistance to tearing. Additionally, there are guidelines for the foil's reflectivity and heat resistance, which are important for its performance in various applications. Compliance with these standards is often verified through testing and certification processes, ensuring that aluminum foil facing products meet the necessary quality and safety benchmarks before they reach the market.</p>

- Q: Behind the wall at the head of bedroom is an elevator, but how can indulate sound? Waht do you think if install silicic acid board of 12 centimeters plus glass wool and splint fo 9 centimeters and then nail soft package background in the rear?

- Soundproofing measures: if conditions permitted, it probably can make soft pakage.

- Q: Is it possible to use black fiberglass tissue as a material for flooring?

- <p>Yes, black fiberglass tissue can be used for flooring. It is often used in commercial and industrial settings due to its durability, resistance to chemicals, and ability to withstand heavy traffic. Fiberglass tissue is a type of composite material that can be combined with resins to create a strong and stable flooring surface. However, it is important to ensure that the fiberglass tissue is properly treated and combined with the right resins to avoid any health or safety concerns.</p>

- Q: Can glass wool be used in exterior wall for thermal insulation?

- It is ok in that it is the same as rock wool in construction work!

- Q: This question asks for methods to properly store black fiberglass tissue to avoid damage or deterioration.

- <p>To store black fiberglass tissue and prevent damage or degradation, follow these steps: Store the tissue in a cool, dry place away from direct sunlight and moisture. Keep it in a sealed, airtight container to protect it from dust and contaminants. Avoid stacking heavy objects on top to prevent compression damage. If possible, use a container with a desiccant to control humidity. Regularly check for any signs of damage or degradation, and replace the tissue if necessary. Proper storage will help maintain the integrity and performance of the fiberglass tissue over time.</p>

- Q: This question asks for a comparison between domestic and foreign aluminum foil, specifically focusing on their differences.

- <p>The differences between domestic and foreign aluminum foil facing primarily lie in material quality, manufacturing processes, and market positioning. Domestic aluminum foil often uses locally sourced materials and may have variations in thickness and quality, while foreign foil might employ higher-grade materials for enhanced durability and consistency. Manufacturing processes abroad may incorporate advanced technology, leading to better surface smoothness and uniformity. Additionally, foreign aluminum foil is often marketed as premium, targeting niche segments with specific requirements for quality and performance. Domestic foil, on the other hand, is generally more affordable and caters to a broader market, including everyday household use.</p>

- Q: What are the differences among glass wool, rock wool and mineral wool?

- So performances are the same. Though materials are different, they are the same as glass wool. They are blown into wool after being melted. Rocks and slags are raw materials, and they will mix together in the same proportion, and finally become glass.

- Q: What are the negative effects on the environment when aluminum foil facing is utilized?

- <p>The environmental impacts of using aluminum foil facing include increased waste generation due to its non-biodegradable nature, leading to landfill accumulation. Aluminum production is energy-intensive, contributing to greenhouse gas emissions. Additionally, improper disposal can lead to water and soil contamination. Recycling rates for aluminum are high, but not all foil is recyclable, and the process itself consumes energy. Overall, aluminum foil facing can have significant environmental consequences if not managed responsibly.</p>

Send your message to us

Thermal Insulation Rubber Tube and Pipe with Insulation Rubber Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords