Insulated Rubber Plastic Sheet / Insulated Rubber Plastic Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

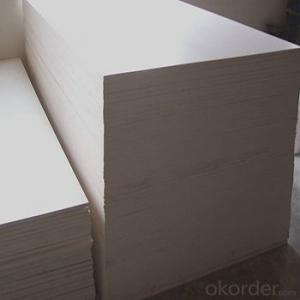

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What steps should be taken to manage and dispose of broken black fiberglass tissue pieces safely and effectively?

- <p>When handling broken pieces of black fiberglass tissue, it's crucial to take safety precautions. Wear protective gear such as gloves, long sleeves, and a dust mask to prevent skin contact and inhalation of fibers. Use a broom and dustpan or a vacuum cleaner with a HEPA filter to collect the broken pieces. Avoid sweeping with a regular broom as it can release more fibers into the air. Dispose of the collected material in a sealed plastic bag, marking it as hazardous waste. Check local regulations for proper disposal methods, as fiberglass may require special disposal procedures.</p>

- Q: This question asks for guidance on the proper cleaning and maintenance methods for black fiberglass tissue to ensure its longevity and appearance.

- <p>To clean and maintain black fiberglass tissue properly, follow these steps: 1. Use a soft brush or cloth to gently remove dust and dirt. 2. For stains, mix a mild detergent with warm water and use a soft sponge to clean the surface. 3. Rinse thoroughly with clean water to remove any soap residue. 4. Dry the area completely with a soft cloth to prevent water spots. 5. Avoid using harsh chemicals or abrasive materials that can damage the fiberglass. 6. Regularly inspect the tissue for any signs of wear or damage and address them promptly. 7. Apply a UV-resistant coating if recommended by the manufacturer to protect against sun damage. Proper care will help maintain the appearance and longevity of your black fiberglass tissue.</p>

- Q: This question asks about the advantages of black fiberglass tissue in terms of environmental protection compared to other materials.

- <p>The use of black fiberglass tissue offers several environmental benefits. It is a lightweight material that can reduce the energy consumption required for transportation. Additionally, it has excellent thermal insulation properties, which can lead to energy savings in buildings and reduce greenhouse gas emissions. Black fiberglass tissue is also resistant to moisture and rot, reducing the need for replacement and disposal, thereby decreasing waste. Furthermore, it is made from glass, a material that can be recycled, contributing to a circular economy and reducing the environmental impact of material extraction and production.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material within walls?

- <p>Yes, black fiberglass tissue can be used for insulation in walls. It is a type of fiberglass insulation that is often used in residential and commercial buildings due to its effectiveness in reducing heat transfer and providing thermal insulation. Black fiberglass tissue is made from glass fibers and has a high resistance to heat flow, which helps to maintain a comfortable temperature inside the building. It is also known for its durability and resistance to moisture, making it a popular choice for wall insulation. However, it's important to follow proper installation procedures and safety precautions to ensure the insulation's effectiveness and to protect against potential health risks associated with fiberglass.</p>

- Q: How effective is fireproofing glass fiber cotton?

- Fire-resistant glass fiber cotton is very good. More holes the fibers have, more breathable, warm, fluffy and soft it will be. This is because air is stored in holes. More holes it has, more air it will be. Moreover in the isolation layer, more air content it has, more permeable and thermal insulating it will be.

- Q: Explain the distinctions between aluminum foil facing and tin foil, including their composition and uses.

- <p>Aluminum foil facing and tin foil are both thin sheets of metal used for various purposes, but they differ in composition and properties. Aluminum foil facing is a thin layer of aluminum bonded to a substrate, often used in construction for insulation, while tin foil is pure tin and is used for wrapping food or as a decorative element. Aluminum foil is lightweight, corrosion-resistant, and conducts heat well, making it ideal for cooking and insulation. Tin foil, on the other hand, is less common in everyday use due to its higher cost and lower durability compared to aluminum. It is often used in niche applications such as art and craft projects or for certain types of food packaging that require a barrier to light and oxygen.</p>

- Q: How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q: Specifications and models of glass wool

- Models of glass wool: 32kg / 50mm, 48kg / 50mm, 80kg / 50mm, 96kg / 25mm, 80kg / 25mm

- Q: Hi, I have got a physics question and was just wondering about it.. Can someone pls tell me how does roof insulation work? how is it effective? How does the insulation changes the heat circulation and transfer inside a house?I know that the insulation prevents radiation from the sun and overheating.. but any more details about radiation, convection and conduction of heat pls?

- Well insulation makes a dead air space (air is stagnant). Since the air is not moving the transfer of hot and cold is slowed down considerably. But since you have to create cross ventilation to reduce rotting in wood and the build up of explosive gasses. Its a crap shoot that it even does any good. Radiation is heat so that's covered by the dead air space. Convection is usually not an issue with the cross venting. Also for conduction the insulation should slow it down considerably.

- Q: Plastic tube most afraid of what the East unitary

- The bonding strength of the gypsum board and the extruded polystyrene plate is ≥010MPa, and the interface is in the extruded polystyrene board The bond strength of the bonded gypsum and the composite plate is ≥010MPa The combustibility of the composite plate reaches B1 level Construction technology points: the installation of the board between the natural close (including the long board) does not leave; for long board, should be installed before the hardening of the bonding material can be carried out; per square meter composite board with at least 2 Expansion of the anchor, each commonly used specifications of the composite board at least 6 expansion anchors evenly anchored to the grass-roots wall; external walls and internal wall connection should be extended to the wall, the width should not be less than 300mm; And wall bonding area ≥ 30% Applicable conditions and scope: hot summer and hot summer and warm winter area outside the building insulation works

Send your message to us

Insulated Rubber Plastic Sheet / Insulated Rubber Plastic Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords