Magnesite Alumina Spinel Brick for RH Refining Furnace - Unburned Magnesium-Aluminate Brick and Snorkels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

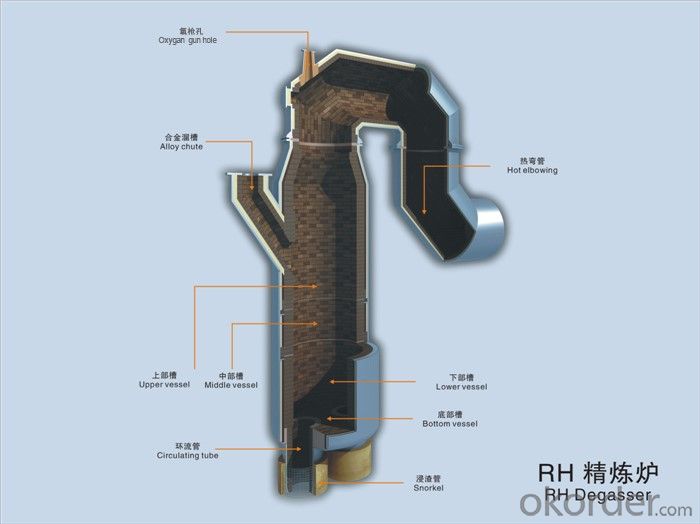

Refractories for RH refiniing furuace

Our company has chrome-free refractories integration technology for RH reflning furnace . We can provide customers whole service Iife solutions including overall design , optimal configuration , comprehensive masonry,on-site maintenance , and used refractories recovery and disposal . As the main drafter of T/ACR10003-2017 Periclase-spinel bricks for RH refining furnace ( a group standard of The Association of China Refractories Industry ), our company develops the series magnesium-aluminate spinel unburned bricks for RH refining furnace , which have been appraised as the green and environment friendly products by the expert committee of The Association of China Refractories Industry. The products are featured with high production efficiency, energy saving, environmental protection, superior performance, long service life and so on. Tested by Hubei Refractory Product Quality Supervision and Inspection Station, the product meets the requirements of Q/MGN 007-2018 standard. The products play an exemplary role in the green development of refractories, and reach the international advanced level.

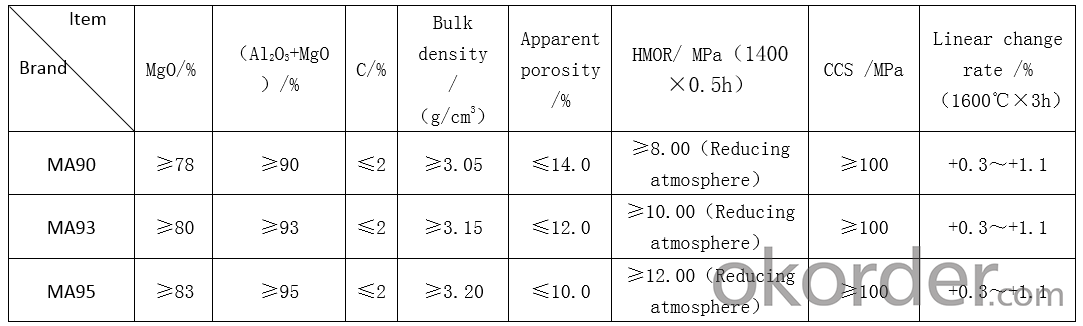

1、Magnesium-aluminate spinel nuburned brick

The magnesium-aluminate spinel unburned bricks are prepared using high quality fused magnesite as main raw material, adding special additives, high pressure shaping and low temperature heat treatment. The bricks are featured with good thermal shock resistance, good corrosion and erosion resistance. Products with different brands are suitable for different service areas.

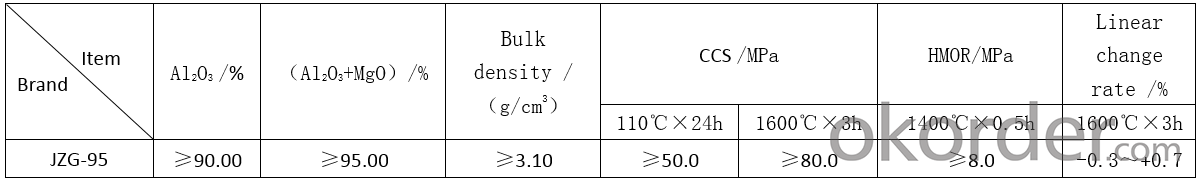

Physical properties and chemical composition of Magnesium-aluminate spinel unburned brick

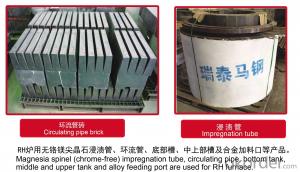

2、Snorkels

The RH refining furnace snorkels are comprehensively lined using MA95 magnesia spinel bricks and high quality corundum spinel castables. The circulation tubes are assembled using MA95 magnesia spinel bricks. The products are featured with good corrosion and erosion resistance, and thermal shock resistance.

Physical properties and chemical composition of Snorkels

- Q: What are the uses of magnesia spinel brick in the industry?

- Instead of magnesia chrome brick sand manufacturing magnesia spinel brick used in cement kiln, not only to avoid the chrome pollution, but also has good resistance to spalling;

- Q: What is the primary crystal phase? What is the secondary phase?

- The properties, quantities, distribution and bonding state of the main crystalline phases of refractory determine the properties of the products directly. A lot of refractory products, such as mullite brick, corundum brick, magnesia brick, magnesia spinel brick, silicon carbide refractory products, etc., are the main crystalline phase named. What is called a crystalline phase? The second phase and second phase or second phase, refers to the refractory material and the main crystal under high temperature and liquid phase coexist, the number and influence on high temperature properties of materials is the main crystal phase is small second phases. As to the main crystalline phase of periclase magnesia chrome brick, magnesia brick, magnesia brick and magnesia calcium brick respectively containing Cr spinel, spinel, forsterite and calcium silicate two are secondary phase.

- Q: Spinel refractory brick air-cooled razheng times

- The components of magnesia alumina spinel refractories can be magnesia alumina spinel, excessive alumina, or magnesium aluminate spinel with excessive amount of Magnesium Oxide.

- Q: Is magnesium spinel harmful to the body? Such as title magnesium spinel, harmful to the body?

- Extremely harmful! Studies have shown that brain tissue has affinity for aluminum, and excessive deposition of aluminum in brain tissue can cause memory loss, mental retardation, slow action and aging.

- Q: What's the difference between iron spinel and magnesium aluminum spinel?

- Spinel is a mineral of magnesium aluminum oxide, because it contains elements such as magnesium, iron, zinc, manganese and so on

- Q: Spinel compound brick composite layer pollution layer does not affect the use of theoretical basis for it

- The study of mg Al spinel synthesized with MgO raw materials and Al2O3 raw materials (calcined alumina or alumina) has begun as early as 1930s. Magnesia alumina spinel was synthesized from industrial alumina and activated alumina in 1939 and used for making bricks. In 40s, people found that the addition of alumina powder in magnesia could improve its thermal stability, this is actually a spinel bonded brick. When the magnesia brick is mainly used in cement kiln, but in addition to the production of white cement kiln, it was replaced by magnesia chrome refractories.

- Q: What are the characteristics of Mg rich spinel and aluminium rich spinel?

- Occurs in the contact metamorphic zone of acid intrusive rocks and dolomite and dolomitic limestone, and is associated with forsterite, diopside and so on. It is also found in peridotite, Kimberley rock, magnesian porphyry and some crystalline schist.

- Q: The difference between aluminium refractory and magnesia refractory

- Magnesia refractory belongs to alkaline refractory materials refers to refractory products such as magnesia magnesia brick magnesium iron spinel magnesium aluminum spinel magnesia ramming materials and other products of raw materials is the main crystal phase is periclase magnesia products

- Q: What is the significance of the synthesis of mg Al spinel? What are the main approaches?

- The spinel has high hardness, chemical stability, high melting point and good properties, high temperature resistance in various melt erosion is very strong, so the orebody in spinel, improve the high-temperature performance of the product. Although the spinel has the above properties, the natural magnesium aluminum spinel is very few and can not meet the needs. Therefore, the synthetic method is usually used in modern times.

- Q: Characteristics of sintered spinel used in refractory zzjsnc

- Sintered aluminum magnesium spinel has good anti erosion ability, anti abrasion ability of good heat shock stability and its main use: instead of magnesia chrome sand manufacturing aluminum magnesium spinel brick used in cement rotary kiln to avoid the chrome pollution but also has good resistance to spalling

Send your message to us

Magnesite Alumina Spinel Brick for RH Refining Furnace - Unburned Magnesium-Aluminate Brick and Snorkels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Ruitai Ma Steel New Materials & Technology Co., Ltd.

Ruitai Ma Steel New Materials & Technology Co., Ltd.